- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller table

Results for

Roller table - Import export

FEMIA INDUSTRIE

France

Pulls off the husks of unprocessed ears of corn.Machine primarily comprised of a roller table, a vibrating feeder and of a variable speed conveyor with its hopper in the upper portion. The roller table is comprised of 4, 8, 12 or 16 “Lanes” keeping in mind that a “Lane” comprises 2 axes with rollers. Range of various husker rollers according to the variety of corn processed Regular feed thanks to a variable speed conveyor belt and a vibrator that aligns the ears before the roller table. Recovery of the husk and silk waste under the roller table.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Well-rounded: The ASP 560 derinder was designed specifically to process round cuts such as ham, shoulder and haunch. Advantages Clean removal of the rind without remnants Perfect speed regulation in combination with the Weber tension roller Variable adjustment of the rind or cutting thickness Moveable with swivel and fixed castors Space-saving With integrated bucket support and low space requirement User friendly Foot lever as standard Options: Special tables Special rollers Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Well-rounded: The ASP 460 derinder was designed specifically to process round cuts such as ham, shoulder and haunch. Advantages Clean removal of the rind without remnants Perfect speed regulation in combination with the Weber tension roller Variable adjustment of the rind or cutting thickness Moveable with swivel and fixed castors Space-saving With integrated bucket support and low space requirement User friendly Foot lever as standard Options: Foot switch or body operated lever Special tables Special rollers Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Doubly well-rounded: The Skinner ASP 560 D is an open derinding and defatting machine for round cuts, such as ham, shoulder and haunch. Advantages Clean and fast removal of rind and simultaneous removalof shoulder fat Perfect collection of rind and fat Variable adjustment of the rind and cutting thicknessfor fat removal Two workflows in one machine Toolless removal and assembly of all parts to be cleaned Modern, hygienic design Ergonomic machine design Integrated crate shelf Space-saving Options: Application-specific table for ham/shoulder without bone Extended discharge table Special tension rollers

Request for a quote

NEAUSTIMA UAB

Lithuania

Technical needle punched felt used: - as acoustic material for acoustic panels/walls - in ironing industry for ironing rollers and tables

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MECANUMERIC

France

Pure water jet cutting machine MDE range allows VHP pure waterjet cutting. Available with different pumps and options, it is designed mainly for tissu and leather industries. Structure : - frame single block in welded steel - mobile gantry in welded steel - stainless steel tank - plastic or aluminum honeycomb coating - 3-turn rotary table for cutting / loading and simultaneous nesting / unloading (MDE-R only) Kinematics : - guidance by stainless steel precision linear rails with preloaded ball slides - XYZ transmission by pre-loaded ball screws (double X-axis motorization) - motorization by AC brushless motors - rotative table with cross-roller crown (MDE-R only) Numerical control : - Numerical control MECANUMERIC CN7000 ISO with 40 Gb hard disk - MHI on control desk with a 15-inch touch screen - Data input by Ethernet link, USB port Features : TYPE MDE MDE-R X-axis travel in mm 1005 1050 Y-axis travel in mm 755 750 Z-axis travel in mm 75 50 Max. speed in mm/sec 30...

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is designed to operate quickly and precisely lock’s holes on aluminum and PVC profile, without releasing the workpiece. Copy router with 1 vertical and 2 horizontal spindle motors ( 3 x 1.1 Kw 12.000RPM) Designed to perform quickly and precisely lock’s holes on 3 sides of the aluminum profile without releasing the workpiece Pneumatic 2 x horizontal and 2x vertical clamps Horizontal and vertical pneumatic tracers with 3 diameters Ø 5, Ø 8, Ø 10 mm Horizontal & vertical templates with standard figures for Aluminum and PVC profiles Smooth movement, high precision and great sensitivity provided with gas spring and ergonomic handles 1 m of roller support table at the right (with ruller) and left side Spray tool lubrication system OPTIONAL ACCESSORIES • Additional router bits with Ø5mm, Ø8mm and Ø 10mm • Additional collets with, Ø 8 and Ø10 • Special templates Videolar TECHNICAL SPECIFICATIONS 3x1.1 kw 1 P 230 V 50-60 Hz 6-8 Bar 8 lt./ min.

Request for a quote

MOSCA GMBH

Germany

•Corrosion-resistant ultrasonic sealing system with electronic self-calibration •High-end Standard 6 sealing unit •Wear-free DC drives with integrated electronics •Stepless turnable control panel for many-sided operation •Adjustable strap tension via control panel •Switching from maximum to material-friendly Ecospeed in the control •Quick strap coil change •Automatic strap threading system •Strap end detection with ejection of remaining strap •Automatic strap loop ejection •4 castors, 2 of them lockable (Ø 80 mm) •CE marking inclusive conformity declaration •Potential-free contacts to upstream and downstream machines •Continuously adjustable conveyorspeed from 0-1 m/s •Parameter control panel for setting strapping parameters •Selector switch for pass, single, double or multiple strapping •Machine completely corrosion-resistant (main use of V4A stainless steel) •IP 56 protection class design •Sensitive components (e.g. motors) are equipped with additional covers

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

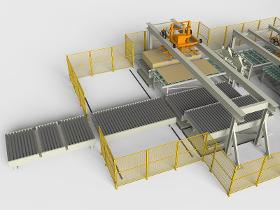

The boards to be coated are fed to the raw-board-handling section where they are separated to allow their surfaces to be cleaned. Features, function A forklift truck is used to place the board stacks on to a roller table from where roller conveyors or horizontal transfer carriages equipped with roller conveyors transport them to one of the two separating station's places. A suction carriage removes the top board from the stack and places it on a conveyor that takes it to the surface-cleaning machine. Advantages The two redundant stacking places allow the short-cycle press to be supplied without interruption. They make it possible to feed new stacks of boards without the need to shut the machine down

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

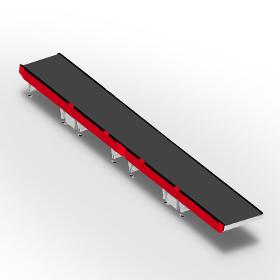

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

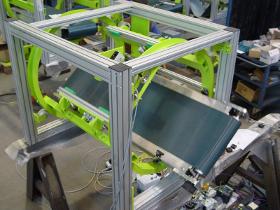

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

TRAPOROL’s special polydirectional roller rails can be used wherever flat conveyed items have to be turned, sorted and shifted in different directions. Note: A and B edges should be mounted alternately next to each other; thus the rollers are arranged shifted in order to realize convenient roller distances. Series ARL 40, fits for ARS 40 Series ARL 48, fits for ARS 48 Series ARL 60, fits for ARS 60 Series ARL 80, fits for ARS 80 Series ARL 120, fits for ARS 120 Versions: — galvanized (untreated cut edges) — stainless steel — powder coated (RAL standard colors) — Special dimensions on request — on request, we manufacture complete tables, roller conveyor

Request for a quote

RISUS MACHINES

Turkey

-It is designed for assembly and test of roller shutters. -Automatic turning mechanism -2 Axis motor controlled -Electro-pneumatically controlled -15.6” Pc controlled touch screen Remote control service

Request for a quoteResults for

Roller table - Import exportNumber of results

15 ProductsCountries

Company type