- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot cell

Results for

Robot cell - Import export

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Ideal automation solutions for loading and unloading of parts on machining centres, presses, measuring stations, etc… Convenient, accurate, repeatable and reliable! The CLA Robot Cell is composed of the following: - A polyarticulated robot or scara with specific grippers - A camera device for part recognition - Automatic camera calibration - Parts loading/unloading system - Protection (cage, mats, detection, etc) - Each application is studied and simulated in order to define the ideal solution - Microplates screening. CLA is a center of expertise of Mitsubishi robots

Request for a quote

REP INTERNATIONAL

France

REP AUTOMATED SOLUTIONS Automation is adapted to the needs and objectives of each customer. An infinite number of possibilities for the following operations Feeder channels Evacuation Flash and gum cutters Evacuation Spraying of release agent and / or cleaning of the mold Loading of inserts Demoulding of finished parts Visual control of conformity and many others... 3 levels of automation possible o Operator assistance Insert loader o Partial automation Demoulding kit (front, rear top, rear bottom, etc.) o Total automation Robotic cell, brushing on horizontal presses, etc.

Request for a quote

MTA ROBOTICS AG

Switzerland

The laser MRC500 is the larger robotic cell that supports point to point laser soldering from above. The standardized platform is based on a flexible and modular concept that can be adapted to a range of processes from fully-automated in-line to stand-alone semi-automated processes. The frame of the laser MRC500 is designed to ensure the safety of the operator during the laser soldering process. Furthermore, it also provides maximum accessibility to the working area. The laser robotic cell is only equipped with mta MLH45 laser head. The main features of our laser MRC500 include: Welded frame construction 3-axis Cartesian robot 500x500mm working area Industrial PC controller with Embedded Windows® operating system Intuitive menu-driven mta MotionEditor software

Request for a quote

SYNERLINK

France

EL PAL is a secure robotic cell for palletizing open trays, closed trays, plastic crates, bundles, etc. This robot is integrated with existing equipment to increase efficiency by having an optimized pallet. The pallet settings are indexed according to your cases. The interlayer pick-up function is incorporated within the gripper. EL PAL is totally designed to be interfaced with any SYNERLINK machines.

Request for a quote

MTA ROBOTICS AG

Switzerland

MRC500 soldering platform for robotic soldering from above is a free-standing machine cell. Our design engineers purposes-built the MRC500 for soldering applications then standardized the design. We purpose-built our own platform so we would not need to compromise functionality based on the limitations of third-party equipment. Standardizing the design offers three primary advantages. It is well-proven, available faster, and costs less than-off custom designs. Although the design is standard, it is highly flexible. We designed the mechanical structure to work with a wide range of process equipment, material handling, and guarding systems. In its basic configuration, the MRC500 is a free-standing, semi-automated machine. At the other extreme, we can outfit it with SMEMA conveyors, collaborative robots, turntables, and many other systems.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

FÖHRENBACH GMBH

Germany

The straightening machine RM-1000 was developed for straightening deep-hole drills, as 4- and 6-axis version. The radial run-out of a drill is straightened using the 4-axis version. The 6-axis machine additionally corrects the camber of the shank and the head run-out of the soldered carbide drill bits. The maximum length of the drills is 1,000mm, the accuracy of the straightening process is 0.08 mm (depending on the work piece). An exportable straightening protocol is created for each straightening process. A robot cell is available as an option. Using this robot cell, the insertion and removal of the drills is performed. The robot cell is mobile and can be disconnected at any time in order to allow manual straightening processes.

Request for a quote

GRAVOTECH

France

COMPACT The Fiber laser robust design and high-quality optical components guarantee high strength and low maintenance. Whether integrated on production lines or robotic cells, its implementation is simple in all mounting positions. The laser marker can be oriented to the part surface to significantly reduce installation times and costs. INDUSTRIAL Equipped to meet the needs of Industry 4.0 in terms of identification marking, the Fiber laser marker is equipped as standard with full network communication ports allowing full compatibility with all PLCs brands and ensure quick and cost-effective integration. POWERFUL This laser marking machine is available in several powers, 20W, 30W and 50W. The 20W laser head is adapted for most of the applications for a surface marking, 30w is the solution for your fast and high-contrast markings, and 50W is the most suitable solution for deep laser markings.

Request for a quote

METAL TECHNOLOGY GROUP

Bulgaria

CNC turning machines Vertical CNC turning machines Vertical CNC milling centers Horizontal CNC milling centers Robotic cell designed for fettling and deburring of castings

Request for a quote

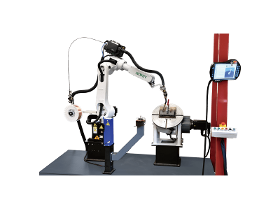

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

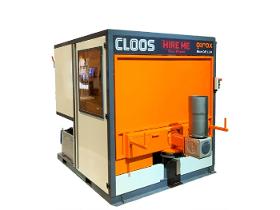

KEY PLANT AUTOMATION LTD

United Kingdom

High performance plug and weld robotic welding cells. Cost effective, production boosting and floor saving, the pay by the hour robotic welding cells are delivered ready to weld, simply plug and go – it’s as easy as that! All cells are two station, Loading whilst welding, and are protected by a light barrier and safety fence. Hassle free delivery – straight to your facility and workshops. With their one lift, easy to transport modular design, the robotic welding cells are delivered direct, hassle free to your facility. Pay by the hour rental Ready to use, plug and weld Cloos welding technology One lift, easy to transport Save production floor area

Request for a quote

FOXLASER

Bulgaria

FoxLaser offers all types of welding of ferrous and non-ferrous metals: 7-axis robot cell for MIG/MAG welding. Positioner up to 5 tons. MIG/MAG – electric arc welding in a protective gas environment with a melting electrode. TIG – electric arc welding in a protective gas environment with a non-melting electrode and with automatic supply of additional material. TIG MICRO-WELDING with PUK-U3. MAW – manual metal (electric) arc welding. SPOT electric resistance welding. We have 3D welding tables for assembling complex sheet and tubular structures. Their dimensions are 3000/1500/200 mm and 2400/1200/200 mm. The use of special attachments and fixtures or the assembly of several tables together makes it possible to increase the size of the assembled structures.

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Welding and cutting processes Depending on material and sheet thickness following processes are used: GMAW - Gas Metal Arc Welding (MIG/MAG) GTAW - Tungsten Inert Gas Welding (TIG), Cold & Hot Wire PAW - Plasma arc welding or cutting FSW - Friction Stir Welding Laser-Hybrid Welding RSW – Resistance Spot Welding igm robots may be used for all non-contact welding and cutting processes. Power sources from many well-known manufacturers can be integrated with our robot systems for welding and cutting applications. Products range from digital inverter power sources for MIG/MAG welding, TIG applications, plasma cutting and welding apparatus to high-capacity devices for the tandem process. Brushing, Grinding and Handling - Manipulation using Robots Through the possibilities afforded by a modular configuration of robot cells and the integration of diverse tools in the robot control sequence, significantly better throughput times and constant process qualities can be achieved. As a...

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

Your #1 source for welding automation and positioning equipment hire. We will not be beaten on price. Key Plant will undercut any genuine quote. We have comprehensive stocks of high quality and reliable weld automation, handling and positioning rental equipment. From welding rotators, tank turning rolls and welding manipulators to pay by the hour, plug and weld robotic welding cells – find your ideal rental solution today. A major advantage we have over our competitors is that, as the manufacturer we have the ability to keep an extensive level of available ‘rent-ready’ stock. A rental department built over 65 years. Short or Long Term Project? Perhaps you have equipment that requires maintenance or a refurbishment, but cannot afford production downtime? We offer affordable rental solutions to help you keep your production at an optimum level. Rental also enables you to evaluate your needs before purchasing.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Metalworking companies are increasingly looking for practical solutions on how to quickly and easily carry out welding tasks. For small quantities, however, automation systems for welding have so far been difficult to implement, from an economical point of view. At the same time, it is becoming increasingly difficult to find qualified welders for manual processing. OTC DAIHEN EUROPE has developed EASY ARC, a new mobile welding robot system for workshop operation, which meets the economic and pragmatic requirements. EASY ARC includes a compact welding robot with intuitive OTC Easy-Teach control, which offers the operator with the perfect weld seam, thanks to the integrated expert system and manufacturer’s own 400A MIG / MAG power source inverter. The robot is mounted on a welding table that is prepared for holding standard clamping elements and equipped with rollers. The simple conversion of the system thus ensures appropriate flexibility in production.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

GIZELIS ROBOTICS

Greece

Gizelis Robotics provides turn-key solutions for machining with robots for all kind of materials like wood, stone, marble, alumium, steel etc. The robot cell consists of: Robot Spindle Robot CNC CAM Software Machining table Automatic tool change Safety fence There is also the possibility for costumers to bring their parts and make them a live demo. Robot CNC CAM software lets you program robots with external axes such as rotary tables and linear tracks as easily as you could program a 5-axis NC machine. Working closely with the highly skilled integrator Gizelis Robotics opened up new opportunities for testing the software which guarantees fast, accurate and easy multi-axis programming for robots.

Request for a quote

GIZELIS ROBOTICS

Greece

Robotic systems assist in such applications thanks to their particularly enabling features. Typical grinding applications include a closed robotic cell to avoid particle dispersion in the surrounding area. A head-bearing robot is located inside as well as various other grinding machines. The robot picks the piece from the feeding area, drives it with precision through all processing stages and places it at the discharge area before it starts all over again by picking the next piece. Depending on the product, a suction system is put in place to keep the robotic cell clean. Robotic grinding is the only option for all related industries since production time is greatly decreased, maximum degree of safety is achieved and, most significantly, it offers flawless quality and consistency to end products. Only companies using robotic systems stand out from the competition, as they can produce optimum products at the lowest possible production cost.

Request for a quote

MEGA-METAL D.O.O.

Slovenia

With a team of highly trained and certified welding technologists, technicians and welders we are welding according to TIG, MIG, MAG and REO procedures for the electrical and machine industry. We use 6 modern robotic CNC cells for the benefit of our clients.

Request for a quote

CIMAT

Poland

Suitable for a manual operation by operator, Suitable for an automatic cell with a robot load/unload, Suitable for an automatic conveyor production, Wheel presence sensors, Imbalance compensation of a spindle, Ergonomic size of the machine, Sophisticated fluids drain system with reservoir, Spindle protection system from metal chips, Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck, Automatic brake and wheel positioning, Fastest balancing cycle time, Fastest tool changeover time, Made of wellknown brands heavy duty components, Servomotor as a spindle drive motor, Software capabilities Valve compensation feature, The best quality, automatic display, Password protection access for operator and shift manager, Any language possible, Industry 4.0 compliant, Static and dynamic imbalance display, Autotest and selfcalibration, Data transfer and communication with master station, CSV file data creation Sophisticated remote diagnostic and support software .

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series painting robots combine high mileage with powerful programming flexibility. With six explosion-proof models, Kawasaki has the right robots for every robot-controlled painting application, from the painting cell with individual robots to integrated multi-robot painting systems. The KF193E is a K-Series industrial robot manufactured by Kawasaki. It has a payload wrist of 12kg and arm of 20kg, a horizontal reach of 1,973mm, a vertical reach of 2,887mm, a maximum painting speed of 1,200mm/s, a weight of 720kg, a floor mounting position, and a 3R ø40 mm that can do a triple roll with its hollow wrist. The industrial robot was specifically created for painting applications.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K Series line of painting robots combines high operational performance with powerful programming flexibility. With six explosion-proof models available, Kawasaki has a robot that will suit any robotic painting application, from a one robot paint cell to complete multi-robot integrated finishing systems.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The K range of painting robots blend top notch operational performance and robust configuration flexibility. It can be ordered in seven distinct models, which ensures that Kawasaki has a robot model that will be a perfect fit for any application from a single robot painting cell all the way up to a full multi robot appointed finishing systems. The specifications of the K-Series painting robots include 12 kg, arm 20 kg payload wrist, 2,665 mm horizontal reach, 4,107 mm vertical reach, 1,200 mm/s maximum painting speed and 3R ø40 mm (Roll Roll Roll - hollow wrist). This series of painting robots is best suited for painting applications.

Request for a quoteResults for

Robot cell - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Industrial robots (11)

- Welding robots (6)

- Painting robots (5)

- Laser - cutting and welding machines (3)

- Robotics (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Aluminium alloys (1)

- Automation - systems and equipment (1)

- Balancing machines and systems (1)

- Food Industry - Machines & Equipment (1)

- Grinding - steels and metals (1)

- Industrial equipment hire (1)

- Marking machines (1)

- Metal straightening machines (1)

- Welding work - steels and metal (1)