- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recycling systems

Results for

Recycling systems - Import export

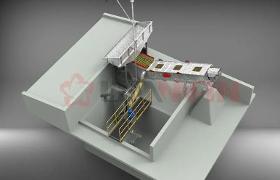

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Recycling Systems Aluminum Recycling Unit With unique design, our aluminum dross recycling system manage the hot dross very effectively. the oxidation and metal loss will be terminated in a very short time, in-house metal recovery could be 70-80%, much higher than any other solutions. The system covers the following equipment.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Press Recycling System Capacity: customized

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Recycling System With unique design, our aluminum dross recycling system manage the hot dross very effectively , the oxidation and metal loss will be terminated in a very short time, in-house metal recovery could be 70-80%, much higher than any other solutions. The system covers the following equipment. Dross stirrer Dross cooler Crusher and screening machine Dust collector Conveyor

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

With unique design, our aluminum dross recycling system manage the hot dross very effectively , the oxidation and metal loss will be terminated in a very short time, in-house metal recovery could be 70-80%, much higher than any other solutions.

Request for a quote

UMMANMAK

Turkey

UMMAN Concrete Recycling System aims to recycle the waste concrete formed in the concrete plant by washing the aggregate and cement so that it can be used in the concrete plant again. The Concrete Recycling Unit recycles the waste concrete, providing great benefits in terms of cost and preventing environmental pollution. ENVIRONMENTALLY FRIENDLY In our period when the protection of the environment is much more important, minimizing the environmental impact and producing harmless to the nature have become a necessity for concrete production plant. Waste concrete left to nature freezes, pollutes underground resources and harms the environment and living things by adversely affecting groundwater. The Recycling Unit is of great benefit to the environment as it recycles the waste concrete into production.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. Recycling is done with the cyclones in our powder coating booths with cyclone. It is preferred because it allows easy and fast color change. The powder particles which are not used passes through the cyclone unit before the filter unit. While the particles go down through cyclones with centrifugal effect, the particle that cannot be reused is sent to the filter unit and filtered there. The parts which are suitable for recycling are recycled to the system for reuse. Multi and mono type cyclone units are used in our booths. Both types offer efficiency with recycling systems, practicality with easy color changing. In filter cabins, it is necessary to change

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. In our powder paint booths with filter, the air is sucked through the filters while the unused powder particles are held by filters. The filters are automatically and periodically pumped air in reverse direction to direct the powder paint that held by filters to the sieve tanks which is under the cabinet for reusing. As a result of this process, the unused powder paint is recycled. Polyester-Teflon and Sinter-Lamellar type filters are used in our booths. Polyester-Teflon filters are preferred due to their low cost and Sinter-Lamellar filters are preferred due to their long filter life. Both types offer efficiency with recycling systems, economical solution

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The main part of the powder coating lines that we have produced is powder coating booths. Powder coating booths are used to apply powder coating on the material under the most ideal conditions after the surface cleaning process and to prevent the paint particles that cannot hold onto the work piece from being escaped to the environment. Electrostatically charged dye particles adhere to the surface with maximum efficiency and homogeneous spread. The system is preferred because; non-adherent powder is reusable with the recycling system in the booths. As Rota Makine, we design lines with conveyor and robots to offer our esteemed customers who want to make production with high capacity, automation and untouched. Our powder coating booths are categorized as With Filter and With Cyclone because of their different advantages. Powder enameling cabinets for enamel applications are also available in our scope of production. Our powder enamel booths are produced

Request for a quote

ROBINSON CO.

Turkey

It performs the task of separating the light grains and shells of the unwanted foreign substances from the grain with the air flow. The grain is spread over the bottom by a vibrating feeder and conveyed towards the air duct. It is washed by the air flow opposite the movement of the grain, which enters the air channel with a homogeneous distribution. In the meantime, unwanted light grains are separated from the grain by moving with the air. Applications Fields ◾ Food Industry ◾ Flour Mills ◾ Semolina Mills ◾ Feed Mills ◾ Grain Cleaning Plants ◾ Corn Processing Plants ◾ Oil Factories ◾ Plywood Factories ◾ Grain Storage Silos ◾ Corn Mills ◾ Corn, barley, rye, oats, and so on grain processing plants

Request for a quote

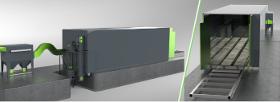

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One particular challenge in the refrigerator recycling process is presented by chlorofluorocarbons such as R 11, R 12 or R 141b, which were used for decades as foaming agents for insulation materials. Since these substances damage the Earth’s ozone layer when released, they must be removed and collected securely in a closed-system pre-processing plant. With ERDWICH, you are assured of the latest, technologically advanced solutions: Whether you’re handling small-scale units or complex refrigeration plant: utilise the expertise we’ve gained in processing over 30 million refrigerator units. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The shredding and sorting of rubbish and refuse is one of the key challenges within the waste management cycle. And with ERDWICH systems, there is a perfect set of solutions for meeting any of these application scenarios: System solutions range from simple shredding machinery through waste volume reduction plant to complete turnkey facilities for shredding and sorting. Deployed in waste sorting facilities, waste incineration plant, hospitals, major catering businesses, light and heavy industry, composting firms or waste reclamation units, ERDWICH wastes no time with waste. With hundreds of machines and systems deployed worldwide, use market-leading ERDWICH technology to ensure your success in special waste recycling. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor that influences the service life and productivity of the expensive machine tools: The key challenge here is therefore process reliability. For efficient swarf management, ERDWICH offers proven centralised and decentralised solutions with the following benefits: Whether centralised or decentralised, Erdwich lets you handle swarf management in double-quick time. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The reclamation of valuable resources from electrical and electronic scrap – a global volume in excess of 40 million tonnes/year – is one of the greatest challenges facing our society. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its turnkey system solutions. ERDWICH pre-processing: All process execution is fully compliant with the new DIN EN 50625/1 rules. Whether you need to handle electrics/electronics, small/large household appliances or specialist items such as fluorescent lamps, PCBs, LCD monitors and PV modules, whether as a mobile or stationary solution: create new value from electronic waste with ERDWICH. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your...

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Recycling System Remove the hot aluminum sIag from the meIting furnace to the hot slag pot. and send it to the frying pot with the forklift truck. Separate hot aluminum ash and aluminum which have different density by rotating blade. Convey the separated hot aluminum ash to cooling barrel automatically.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Dross Recovery Unit for secondary aluminum producer With unique design, our aluminum dross recycling system manage the hot dross very effectively , the oxidation and metal loss will be terminated in a very short time, in-house metal recovery could be 70-80%, much higher than any other solutions. The system covers the following equipment. Dross stirrer Dross cooler Crusher and screening machine Dust collector Conveyor

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai was founded in 1995. We are an ISO 9001 certificated company. We have been providing various models of sow molds to aluminum smelters in America, Australia,Canada, Germany, India, Italy and South Africa for nearly 3 decades. We gradually expanding our product line from sow molds to other castings used in aluminum recycling system, including dross pans, cooling heads, skim tools and other iron and steel castings. Responding to the customer demand, since 2010, we started to design and build dross press and other devices needed for aluminum recycling system, providing solutions for customers to maximize their aluminum recovery rates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Sandblasting cabin also called Shot Blasting Room; It refers to the closed sandblasting area in which sandblasting is carried out with the labor of one or more operators. Sandblasting rooms: It consists of the Cabin, the Sandblasting System, the Recycling System that allows the used sand to be reused, the Ventilation & Filtering System and the Control Panel. It is mostly preferred for sandblasting a large number of parts that do not require a large and automatic machine. Automotive, Steel Construction, Defense Industry etc. preferred in the sectors. Standard sized sandblasting chambers are shown in the table below, although they are produced by BF BLAST in all sizes according to customer needs.

Request for a quote

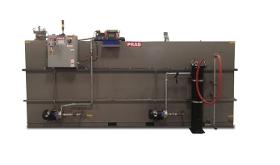

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Proven to reduce new oil purchases by as much as 75%. Extend the life of your oil with the PRAB oil recycling system. PRAB’s Oil Recycling System (ORS) is a centralized, economical solution to the high costs associated with maintaining petroleum- and synthetic-based oils in the metalworking industry. The ORS recycles oils by removing the suspended particles and moisture that shorten the useful life of oil-based fluids, reducing new oil purchases by up to 75%. The system comes available with everything an operation needs to implement a state-of-the-art fluid management program. Each system is designed for easy installation, quick start-up, and simple, efficient operation.

Request for a quote

INSCREEN SA

Greece

Discover the versatility of Inscreen’s Horizontal Zip Systems. Ideal for various applications, these systems offer reliable insect protection . Made from durable, fully recyclable materials, our horizontal zip systems are designed to withstand outdoor conditions while contributing to a sustainable environment. Ideal for very big openings. Single screen max width 6,5 meters. Double screen max width 13 meters.

Request for a quote

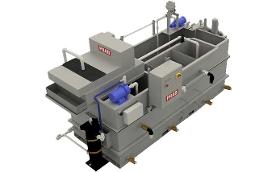

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce coolant waste up to 90%. The effective solution to coolant recycling. The PRAB Guardian™ is a centralized system for recycling used coolants, reducing waste fluids up to 90%, and eliminating concerns about wastewater haul-away liabilities. Typical payback in six to nine months. These versatile and centralized coolant recycling systems remove tramp oils and suspended solids from contaminated coolant, control bacteria and can adjust fluid concentration for fluid recovery. Each turnkey system is designed for easy installation, quick start-up, and simple, efficient operation- clearly making it the best coolant recycling solution on the market today. For a calculation of just how quickly you will pay this system back, call us for a free ROI estimate.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Process loose metal turnings into flowable chips. Scrap metal recycling system couples volume reduction with fluid separation to produce dry chips and reclaim 99% of valuable coolants and cutting oils. The ideal solution for scrap metal consisting of flowable chips and loose turnings

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding. Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements. Also in this area, Geppert Ruhrtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas.

Request for a quote

MACFAB SYSTEMS LTD

Ireland

A great solution for reducing the number of bins in your business. The Crushing chamber is totally enclosed and timed locked by a safety switch during the crushing process. An excellent choice for Hotels, Bars and restaurants to reduce the large volume of empty glass beer and wine bottles generated during events or weekends. Can save valuable space on there business stores area.

Request for a quote

OMECHA UAB

Lithuania

Vibrating screen for recycling systems. Bulk product screening and separation. Material flow and screening for waste, metal scrap, WEEE scrap, and copper wire recycling.

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We offer standard EPS recycling machines and equipment with good quality and competitive prices. Our range of EPS recycling machinery is as follows: * EPS crusher and grinder * EPS deduster - dust collection unit with scrap silo and dust filters * EPS scrap mixing unit with scrap and fresh material silos * EPS scrap silo (half fabric, half metal or fully metal) * Options for material transfer and handling system with or without automation For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quote

FLEXPLAS

Turkey

WHY THROW MONEY AWAY? If you are producing hoses, tubes, or profiles, ideally there would be zero scrap from your production operation. However, even the most efficient operation produces a percentage of scrap material. This is the money that you are losing. Why throw money away? Since the cost of plastic material, which has been constantly rising over the past years, is a large overhead cost to your business, Flexplas offers you very efficient and economical recycling systems to save up your money. With Flexplas recycling lines, you will be able to recycle your scrap plastic material and re-feed them back into your production for additional cost savings. Using an in-house Flexplas Recycling System you will be able to utilize a very high % of scrap back into your main production representing a very fast return on investment.

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 40-12-016 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 40-11-016 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With double centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quoteResults for

Recycling systems - Import exportNumber of results

62 ProductsCountries

Company type

Category

- Vacuum cleaners, domestic (5)

- Dustbins, waste bins (4)

- Goods handling systems, continuous (3)

- Paint spray guns and accessories (3)

- Aluminium alloys (2)

- Compactors and crushers (2)

- Flour milling - machinery and equipment (2)

- Recycling - machines and installations (2)

- Cardboard and cardboard products - processing machinery (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Coating machinery (1)

- Concrete blocks (1)

- Containers (1)

- Conveyor systems (1)

- Display windows (1)

- Granulation, plastics - machinery (1)

- Heat pumps, domestic (1)

- Industrial design (1)

- Kitchens - furnishing (1)

- Marking - diverse products (1)