- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recycling systems

Results for

Recycling systems - Import export

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One particular challenge in the refrigerator recycling process is presented by chlorofluorocarbons such as R 11, R 12 or R 141b, which were used for decades as foaming agents for insulation materials. Since these substances damage the Earth’s ozone layer when released, they must be removed and collected securely in a closed-system pre-processing plant. With ERDWICH, you are assured of the latest, technologically advanced solutions: Whether you’re handling small-scale units or complex refrigeration plant: utilise the expertise we’ve gained in processing over 30 million refrigerator units. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The shredding and sorting of rubbish and refuse is one of the key challenges within the waste management cycle. And with ERDWICH systems, there is a perfect set of solutions for meeting any of these application scenarios: System solutions range from simple shredding machinery through waste volume reduction plant to complete turnkey facilities for shredding and sorting. Deployed in waste sorting facilities, waste incineration plant, hospitals, major catering businesses, light and heavy industry, composting firms or waste reclamation units, ERDWICH wastes no time with waste. With hundreds of machines and systems deployed worldwide, use market-leading ERDWICH technology to ensure your success in special waste recycling. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor that influences the service life and productivity of the expensive machine tools: The key challenge here is therefore process reliability. For efficient swarf management, ERDWICH offers proven centralised and decentralised solutions with the following benefits: Whether centralised or decentralised, Erdwich lets you handle swarf management in double-quick time. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your project enquiry!

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The reclamation of valuable resources from electrical and electronic scrap – a global volume in excess of 40 million tonnes/year – is one of the greatest challenges facing our society. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its turnkey system solutions. ERDWICH pre-processing: All process execution is fully compliant with the new DIN EN 50625/1 rules. Whether you need to handle electrics/electronics, small/large household appliances or specialist items such as fluorescent lamps, PCBs, LCD monitors and PV modules, whether as a mobile or stationary solution: create new value from electronic waste with ERDWICH. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your...

Request for a quote

BÜRKLE GMBH

Germany

The compact jerrycan, made of electrically conductive HDPE, is especially well suited for use in explosion-proof areas. With a specific surface resistance of <105 ohms, the canister has a very high electrical conductivity. When correctly earthed, it prevents the danger of ignition due to an accumulation of electrostatic charge. The canister thus helps to meet the requirements of the ATEX 137, TRBS2153 and CENELEC 50404 guidelines. The plastic industrial canister is non-rusting and can be disposed of with no problems in the recycling system. It can be used for dispensing and storing combustible and highly flammable liquids of explosion groups IIA, IIB and IIC, such as laboratory waste in industrial applications or mining. Due to its narrow width of 6.5 cm or 12.5 cm, the space-saving canister requires very little room, making it suitable for use in very confined spaces.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding. Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements. Also in this area, Geppert Ruhrtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas.

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 40-12-016 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 40-11-016 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With double centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 30-12-016 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Standard design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 30-10-046 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: Open discharge of liquid components Constructional features: Drive without clutch Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: ODB 260-71-107 Manufacturer: GEA Westfalia Separator Description: Self-cleaning disc centrifuge Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With double centripetal pump Constructional features: Drive without clutch Design of hood and sediment collector: Removable hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 100-12-517 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Pressure tight design Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: DA 100-12-117 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Drive without clutch Design of hood and sediment collector: Hinged hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: SDC 210-12-107 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With single centripetal pump Constructional features: Drive without clutch Design of hood and sediment collector: Removable hood Type of drive: Flange type motor vertical

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: SDC 110-11-003 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification with concentrate recycle system Liquid discharge: With double centripetal pump Constructional features: Standard design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

GRUBER SYSTEME HORST GRUBER

Germany

Oecostep collecting stations become indispensable elements in all areas using different bins for waste and recyclable materials: hospitals, clinics, medical centers, administration and headquarter facilities, senior and nursing homes, laboratories, washing rooms and lavatories, cafeterias, catering, hotels, food industry – oecostep collecting stations show their efficiency in action everywhere. Mobile or fixed, the step bins help to reduce cleaning costs and to make working procedures easier. Trolleys - dedicated to oecostep collection bins - are available. This ensures a simple, clean and hygienic disposal!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

The system RS 6000 is a high-performing recycling system that cleans large oil volumes in several process stages. This system was constructed for many years of reliable work without service. By several process steps such as heating and settling, large amounts of water and dirt are removed. Additionally, the usage of settling technology and a pre-filter increases the service life of the main filter. The RS 6000 can be operated manually, semi- automatic, and fully automatic. It is the ideal recycling system for central treatment of, for example, cutting oil or cooling lubricants. 400 V asynchronous-motor Robust, stable gear pump Free choice of settling- and heating times and the number of filter passes Either manual, semi-automatic, or fully automatic operation Displays for operation- and process status Flow regulation for high viscosity oils Element lifter for fast filter exchange

Request for a quote

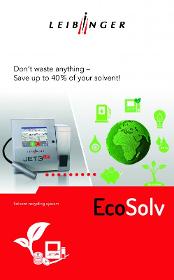

PAUL LEIBINGER GMBH & CO. KG

Germany

The EcoSolv solvent recycling system ensures LEIBINGER inkjet printers consume the smallest possible amount of solvent. A JET3up or JET2neo series printer with EcoSolv consumes up to 50% less solvent. EcoSolv recovers the evaporated solvent from the printer exhaust air through condensation and directs it back into the supply tank. Solvent recovery allows you to save cash and protect the environment!

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 2,8 l /m. 15 KW, 32A. With closed parts cleaning cabin in stainless steel, incl. vapour exhaust system, integrated light and compressed air supply. Access via brush curtains. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 1 m hose with small pistol, quick change coupling and nozzle SR-ST inside cabin. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. With closed parts cleaning cabin in stainless steel, incl. vapour exhaust system, integrated light and compressed air supply. Access via brush curtains. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 1 m hose with small pistol, quick change coupling and nozzle SR-ST inside cabin. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle SR-ST. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

All media contacted parts are resistant against acid and demineralised water, media must be compatible with V2A stainless steel, version 1.4301. Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 1,8 l /m. 10 KW, 16A. 5 m hose with large pistol, hand screw coupling and lance ESR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle ESR-ST. Hoses with quick change couplings at the device.

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile. Parts cleaning collector with sturdy drip-off grid, 80 kg load capacity, 30l. Water recycling via special sedimentation system with filter monitoring. 60 l water tank, 5 l cleaning agent reservoir, stepless adjustable pressure, metering device for cleaning agent, water shortage control, overheat fuse. Volume 2,8 l /m. 15KW, 32A. 5 m hose with large pistol, hand screw coupling and lance SR-LA 600, 2 m hose with small pistol, quick change coupling and nozzle SR-ST. Hoses with quick change couplings at the device.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

AUWEKO GMBH

Germany

Smart and minimalistic: SKYLINE is the name of a high-end recycling system which we have designed in 2017. As separation of recyclable materials is becoming increasingly complex, a system with clear contours and convincing benefits meets these requirements. The brushed stainless steel surfaces are easy to maintain with standard cleaning agents: Shiny material that is predestined for continuous use and can withstand high stresses. The SKYLINE series combines the advantages of large capacity (100 litres per compartment), large openings and certified fire protection.

Request for a quote

AUWEKO GMBH

Germany

Public, highly frequented areas with sophisticated architecture and design, e.g. airports, public transportation stations, exhibition centres, stadiums, hospitals or shopping centres, not only demand waste- and recycling collection systems with an elegant yet subtle design. Requirements for high safety standards are also prioritized. Demands which the AUWEKO TEMPTATION series fulfils brilliantly, and not only with its patented fire safety system. The best solution for recycling in public spaces!

Request for a quoteResults for

Recycling systems - Import exportNumber of results

30 ProductsCountries

Company type

Category