- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production robots

Results for

Production robots - Import export

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

ROLLON GMBH

Germany

The PLUS SYSTEM series of linear actuators consists of highly protected linear units featuring a self-sustaining anodized aluminum structure and a steel re-enforced driving belt. This is a line of exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration. High load capacity,High speed,Low wear and tear,Low friction,Low maintenance.Corrosion resistant version All Plus System series of linear actuators are available with stainless steel elements, for applications in harsh environments and/or subject to frequent washes. The Plus System linear units are made by using extruded anodized Anricorodal 6060 and 6082 aluminum, which houses bearings, linear rails, nuts and bolts and components made of low carbon SS AISI 303 and 404C steel, preventing or delaying corrosion caused by humidity experienced in the environments where the linear units are used.The PLUS SYSTEM series consists of 3 distinct products with different features: ELM,Robot,SC.

Request for a quote

THOMSON MACHINERY BV

Netherlands

The manufacturing landscape is changing at a rapid pace. Gone are the days of large offshore factories with cheap labor. Companies can now build closer to home and enable the shift from mass production to mass customization. Robotics, which has been driving much of this change, also needs to evolve further

Request for a quote

THOMSON MACHINERY BV

Netherlands

Industrial robots can complete tasks with precision and repeatability without requiring stoppages or breaks. This ability to continuously operate without fatigue makes robots highly productive and can lead to a quick return on investment for manufacturers. The precision of robots also means fewer errors are made in the production process, which often corresponds with a decrease in waste and production costs as well.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

robot collecting cups filling solutions for high and fast production needs. Full Automatic Robot Collecting cups then arrangmrnt in special dish suitable for high capacity factories up to 25,000 cups/H

Request for a quote

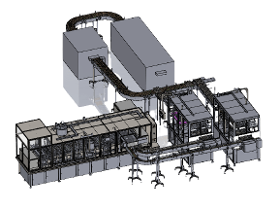

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quote

ELKON GMBH

Germany

ELKON Cement silos are precisely manufactured by the fully automatic welding robots in production molds in ELKON-3 factory which is dedicated only for the production of cement silos. For easy and efficient transportation, ELKON provides a wide range of bolted type cement silos with the capacity of 50, 75, 100, 150, 300 and 500 tons.

Request for a quote

HENGONG PRECISION EQUIPMENT

China

Industrial Robot Intelligent Production Horizontal Machining High-precision Testing The production facility is equipped with more than 400 sets of horizontal machining centers, vertical machining centers and high speed CNC, mainly Mazak, Nachi-Fujikoshi and Doosan. Our company is approved by ISO9001 quality management.

Request for a quote

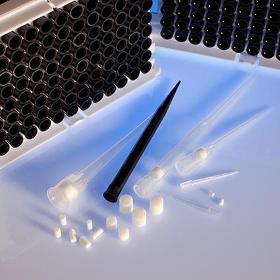

POREX TECHNOLOGIES GMBH

Germany

Maximum consistency in airflow, filter purity, and aerosol containment POREX® Automation Certified Pipette Tip Filters are customized and optimized to meet the fit, air flow, and volume placement of your specific robotic and automated liquid-handling instruments, sample processors and dispensing systems. To streamline laboratory operations and production, these automation and robotic pipette tip filters are backed by the Certified Pure Porex™ Program and: Maximize air flow –Delivers optimal dispensing and pipetting performance across a wide range of liquid volumes. Prevent cross-contamination–Eliminates aerosol bypass and sample carryover. Increase sample throughput–Provides tighter tolerance control for increasing laboratory workflow and reducing instrument downtime.

Request for a quote

GRAVOTECH

France

COMPACT The Fiber laser robust design and high-quality optical components guarantee high strength and low maintenance. Whether integrated on production lines or robotic cells, its implementation is simple in all mounting positions. The laser marker can be oriented to the part surface to significantly reduce installation times and costs. INDUSTRIAL Equipped to meet the needs of Industry 4.0 in terms of identification marking, the Fiber laser marker is equipped as standard with full network communication ports allowing full compatibility with all PLCs brands and ensure quick and cost-effective integration. POWERFUL This laser marking machine is available in several powers, 20W, 30W and 50W. The 20W laser head is adapted for most of the applications for a surface marking, 30w is the solution for your fast and high-contrast markings, and 50W is the most suitable solution for deep laser markings.

Request for a quote

QP PLC

Hungary

The Automated Serial production qualified for the highest standards in CNC machining in a 6000 sqm. The production lines here are made of automated, robotized cells and are able for high precision mass production of different parts for any industry – engine or structural parts, any other components – as well as aluminium and steel products. We have centralised chips and emulsion management, temperature and filtered air control, 7/24 shift pattern.

Request for a quote

QP PLC

Hungary

The Automated Serial production qualified for the highest standards in CNC machining in a 6000 sqm. The production lines here are made of automated, robotized cells and are able for high precision mass production of different parts for any industry – engine or structural parts, any other components – as well as aluminium and steel products. Besides the production for our customers there are Data Matrix Code laser engravers, online production control and support system (OEEm) for full traceability, robotized high pressure washing equipment, tightness Quality CMM machines, assembly and logistic services. We have centralised chips and emulsion management, temperature and filtered air control, 7/24 shift pattern.

Request for a quote

QP PLC

Hungary

Besides the production there are robotized high pressure washing equipment, waterproof with special positioned pins for pricese water targetting, dryer and tracebility control too.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Existing factory workshops and industrial plants can be surveyed three-dimensionally in detail. For new buildings, further extensions and reconstruction in the future, there are spatial coordinates available which are accurate to a millimeter, from which two-dimensional construction plans can easily be drawn. Generation of 3D models From the data gathered by Z+F laser scanner systems and with the LFM software, 3D models of the actual state of the factory or plant (e.g. tubes, steel girders) can be generated. Furthermore, it is possible to generate complete CAD models from the 3D scan data (the so-called point cloud). Clash detection It is possible to simulate manufacturing processes and to carry out collision checks with 3D models. Example: Another production robot of the same type has to be added to an existing plant. Facility management All fixed equipment like cables or tubes is surveyed as well and saved in a 3D database which serves as the basis for future reconstruction.

Request for a quote

INAC

Spain

3D design software to create wooden pallets (INAC PALET CREATOR) Wood preparation machine (1 or 2 preparation tables) Smart Robot Nailing System Palletisation on chain conveyors Production control system

Request for a quote

INAC

Spain

Conveyor and accumulator for wooden profiles from production lines Robotic handling of profiles Box preforming and forming Palletisation of boxes Instruction manual-based software for processing different profiles

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORGECO SPOL. S R.O.

Slovakia

We specialize in the production of metal welded brackets according to the individual drawings and requirements of our customers. We are able to provide high-quality products that precisely meet the needs of our clients. Our production is based on the latest technologies in the industry. We utilize laser cutting and CNC bending of sheet metal, which allows us to achieve high precision and repeatability in our products. Thanks to robotic grinding, we are able to achieve optimal surface quality, ensuring consistent and aesthetically appealing surface finishing. One of the key aspects of our production is ensuring a high standard of corrosion resistance and safety for our customers. For this purpose, we use top-of-the-line COSTA machinery, which allows us to round the edges of components with precision and efficiency. This process not only enhances the aesthetics of our products but also increases their durability and resistance to external influences.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We are a manufacturer of metal pallets, also known as pallet frames, tailored to individual customer requirements, providing flexibility and a personalized approach. We utilize state-of-the-art technologies such as laser cutting and CNC sheet bending to achieve a high standard of precision and quality in the production of our metal pallets, or pallet frames. Robotized welding ensures consistent and reliable quality of joints, which is critical for the safety and longevity of our products. With the help of robotic grinding, we achieve a smooth and aesthetically pleasing surface on our metal pallets, or pallet frames, enhancing their attractiveness and functionality. Our combination of modern technologies and expertise enables the production of metal pallets, or pallet frames, in a wide range of dimensions and shapes, allowing us to meet even the most demanding needs and requirements of customers.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

Metal chair frames are the basis of every solid and durable piece of furniture. Without them, in many cases, the design of the chair would be impossible. As a manufacturer of metal chair frames, we focus on the quality of workmanship and precision in production. Metal chair frames manufacturer - Project implementation process Our machine park includes many CNC numerically controlled machines. It is a technology thanks to which we are able to make chair frames of various shapes and sizes while maintaining high quality. The bending of metal chair frames is performed on CNC mandrel benders, which ensures perfect precision and repeatability of production. Thanks to this, our frames are perfectly matched to the other elements of the chairs with which they will be connected. In our production process, chair frames are welded on a robotic welding station. This not only ensures high joint quality, but also increases production efficiency. Robotization

Request for a quote

PJM MECHANICAL CO.,LTD

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quote

TROTEC LASER GMBH

Austria

The industrial laser engraver is designed to operate 24/7, with the VIN marker achieving a perfect typeface at high speeds. The robust and compact integration laser, with IP 54 protection class, is one of the most compact lasers on the market with only 0.012 m³. Easy integration supports integration into new or existing production lines on industrial robots, manipulators or balancers. Inexpensive and powerful - depending on project implementation, it takes only 15 seconds to engrave a complete VIN and is more economical than many other systems. The VIN marker can also engrave hard metals such as titanium, hardened steel, cast aluminum or others without any problems.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Cable trunking for footfall loading in machining centres PFLITSCH Automobile-Trunking complies with the works standard for many automotive manufacturers and serves as walkable floor trunking in many automated manufacturing lines and robotic production plants, allowing loads of up to 1,200 N and using antislip channelled sheet covering (slip-resistance rating R10). With seven cross sections from 100 mm to 600 mm wide, standard base perforations and universal separating walls, this robust trunking can be placed and combined with other PFLITSCH trunking systems to customer requirements. Your advantages: Walkable floor trunking with high footfall load High strength, wide support spacing Channelled sheet for antislip safety Can be combined with other trunking systems

Request for a quote

LVD

Belgium

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Dolfin KNV series conveyor belt washing machines are parts washing machines used for washing parts produced in series in large quantities. The parts placed at the entry point are moved towards the exit point of the device by means of the conveyor. The parts guided on the conveyor line are washed with high pressure, pre-washing, washing, rinsing, spraying with passivation liquids. At the end of the cleaning process, these parts are dried with pressurised hot air and discharged at the exit point. If desired, it can be integrated into production processes and robotic loading and unloading options are also available. While the entire device is fully automatic, all washing details are parametric. Cleaning is provided at any desired level by means of spray nozzles specially designed according to the part geometry.

Request for a quote

A TECH SUPPLY APS

Denmark

In our moulding departments we are producing items for hear devices and other medical equipment. The demanding quality request from our customers are for us daily business. The production is equipped with handling robots and that´s why we can offer all quantities from prototypes / small production batch sizes to several million items per batch for a competitive price level. We can also offer customer packing from our 2 automatic packing machines. We have for many customers a security stock or an annual framework agreement.

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Robonet: Network operation and remote access ISDES embedded: Weld seam and operating data acquisition system Smartstep: Generating robot programs iPAT: manipulation and the assembling of robot programs i4i: Visualisation of system status Robonet igm software for network operation and remote access from an arbitrary PC to the robot control Transfer of data to one or more machines Remote monitoring of welding and operating data Teach pendant display can be viewed on your notebook or PC ISDES embedded ISDES EMBEDDED is a weld seam and operating data acquisition system for monitoring, documentation and quality assurance of welding processes, as well as for the evaluation of operating data at partially, or fully automated welding robot systems. The ISDES integrated on the control system offers the possibility to record, monitor and evaluate the parameters decisive for the quality as well as the operationally relevant data. isdes embedded functions directly integrated into the...

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Operational availability of the robot installation for production is increased by using an off-line system for generating robot programs. While saving time, programs may be prepared more conveniently in an office environment and simulation test runs (accessibility, computation of cycle time) may be performed. Collisions of the robot with the workpiece or fixtures may be detected at an early stage. Offline programming - Online working Simple robot programming is available through the self developed PC-based off-line programming system, using the original software of the robot control system and the teach pendant K6. Offline programming involves work piece oriented programming in 3D mode using a PC and simulation software. The workpiece is first imported into the programming system as 3D-CAD geometry, then the movements of the robot are determined. For path generation and definition of the processing parameters, a number of automatic functions as well as data bases stored in the...

Request for a quoteResults for

Production robots - Import exportNumber of results

48 ProductsCountries

Category

- Industrial robots (9)

- Automation - systems and equipment (4)

- Aluminium and aluminium alloys (3)

- Finished Metal Products (2)

- Internal transport systems (2)

- Monitoring and control equipment (2)

- Painting robots (2)

- Paper - Printing - Machines & Equipment (2)

- Robotics (2)

- 3D scanner (1)

- Adjustment - machine tools (1)

- Armchairs (1)

- Brakes, servo-brakes and accessories (1)

- Cable ducts (1)

- Cocoa and chocolate - machines and equipment (1)

- Concrete mixers (1)

- Cylinders, pneumatic (1)

- Food Industry - Machines & Equipment (1)

- Food Processing (1)

- Grinding - steels and metals (1)