- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- product adjustment

Results for

Product adjustment - Import export

BELGOMILK IA SA

Greece

The cup falls Feeding station Aluminum placing (preset cap) Waterproofing Dating Carrier’s exit Automatic date placement The cup filling machine has three photocells A photocell to check the filling whether there is any cup or not. Thanks to this photocell system, the machine will not lose the product. If there are no cups, then the machine will not proceed with filling. The photocell control for the aluminum lids, whether there is cup or not, thanks to this system if there is no cup then the machine will not waste the aluminum lids. The photocell control for sealing, thanks to this system it checks whether there are aluminum lids on the cups or not, if there are no lids on the cups then the machine will not reach the sealing unit and the machine stops.. Additional options are possible in the yogurt filling sealing machine Flow filter unit-ΗΕΡΑ Second filling station for filling multiple products Adjustment of placement between cap and cap

Request for a quote

ROBINSON CO.

Turkey

Counterflow cooler is utilized for cooling the feed that comes out from pellet mill in pellet form which is hot, to ambient temperature. It works according to steady air form principle. Air in the external environment contacts the feed in the cooler; while the temperature of the feed drops, warm air is removed from the environment through air aspiration system.Discharge system which is on the cooler, removes cooled feed. Drainage system can be chosen with grid or hydraulic valve depending on the preferred product. Drainage system is adjustable and works according to the capacity. Applications Fields ◾ Feed Plants

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided as a curtain between the roll rolls.

Request for a quote

EOSWISS PHARMA

Switzerland

We carry out the entire technology transfer or production transfer from a manufacturer to a contract manufacturer (CMO, CDMO) for you. Contact us for an initial discussion! In the process, we look for the right CMO for you and prepare a pre-selection. You decide on the best manufacturer, then we carry out the entire transfer for you: •Planning resources •Timetable including work packages •Structure the cooperation with the CMO •Prepare all necessary documents •technical transfer •Adjusting the production parameters, optimisation •we validate the transferred production process •handed over to routine production We bring all the necessary specialists into the project ourselves, or work hand in hand with your internal team. Depending on how it is needed. We carry out transfers very quickly. This shortens the project duration and reduces your costs: They are quickly back on the market! This reduces transfer costs in the long term. Contact us for an initial discussion!

Request for a quote

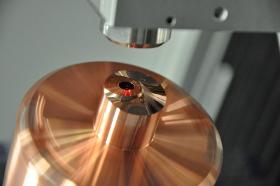

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Special purpose machines are our specialty. We are able to adapt our standard machines to your needs within a short time or to develop and build completely new machines for your application. Our extensive know-how allows us to accompany you from process development through the design and detailed construction of a suitable machine to measurement, commissioning and the start of production in your plant. In addition, even maintenance or product adjustments if necessary.

Request for a quote

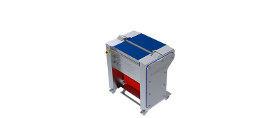

HO-MA GMBH

Germany

Increased output for further processing Tool-free format change Quick adjustment to product formats Selectable direction of rotation

Request for a quote

ROSE PLASTIC AG

Germany

More safety. More efficiency. The new generation of TwistPack packaging tubes convince with user-friendly "twist-lock" closure Maximum flexibility through universal length adjustment Optimal product protection Easy opening and closing through telescopic adjustment

Request for a quote

FERPLAST SNC

Italy

VOLUMETRIC DOSERS KFG SERIES with adjustable cups for powder and granular products Dispenser made entirely of AISI 304 stainless steel, suitable for packaging powder and granular products in preformed bags with volume from 125 to 2000 ml. (depending on the model) The cups are adjustable and indicatively the volume can be reduced to 50% of the maximum capacity. Main features: - sturdy support structure in stainless steel - 25 liter capacity loading hopper - adjustable cups - product discharge cone - start pedal for product unloading

Request for a quote

FERPLAST SNC

Italy

WHEELED VACUUM PACKAGING MACHINE DZ 400 2E WITH TWO SEALING BARS Wheeled vacuum packaging machine with two lateral sealing bars, made of stainless steel (AISI 304) and equipped with volumetric electronic sensor that enables the continuous vacuum control. Tank with with rounded lid for greater usable height in the central part. The compact size of the tank and the high power of the vacuum pump ensure high productivity. The adjustment of the welding time, vacuum and gas placing occur through practical potentiometers positioned frontally. VACUUM MACHINE WITH GAS INJECTION SYSTEM (MAP) Each sealing bar is equipped with two nozzles which introduce gases in different quantities, so the machines are suitable for the packaging of one single use for each sealing bar. When ordering, it is possible to request a modification to the gas inlet system so as to be able to pack two bags per bar by entering the same quantity of gas for each package.

Request for a quote

FERPLAST SNC

Italy

TABLETOP VACUUM PACKAGING MACHINE DZ 400 2T WITH TWO SEALING BARS Tabletop vacuum packaging machine with two lateral sealing bars, made of stainless steel (AISI 304) and equipped with volumetric electronic sensor that enables the continuous vacuum control. Tank with with rounded lid for greater usable height in the central part. The compact size of the tank and the high power of the vacuum pump ensure high productivity. The adjustment of the welding time, vacuum and gas placing occur through practical potentiometers positioned frontally. VACUUM MACHINE WITH GAS INJECTION SYSTEM (MAP) Each sealing bar is equipped with two nozzles which introduce gases in different quantities, so the machines are suitable for the packaging of one single use for each sealing bar. When ordering, it is possible to request a modification to the gas inlet system so as to be able to pack two bags per bar by entering the same quantity of gas for each package.

Request for a quote

FLOTTWEG SE

Germany

Flottweg Sedicanter separates solids from liquids. Its special feature: the solids consist of a sediment with properties ranging between soft and fluid. Typical applications of the Sedicanter are "soft products": ► Biomass, yeast and protein suspensions. ► Fermentation broths and UF retentate ► CIP cleaning liquids and coarse matter-free live sludge ► Fruit juice byproducts and plant-derived raw materials ► Soap separation from oil refining processes The special technical features of the Flottweg Sedicanter: ► Separation of extremely difficult-to-sediment solids by acceleration up to 10,000 gee. ► Hygienic design, thus usable for applications in biotechnology ► Flexibility with fluctuating composition of the feed product by the adjustable impeller ► Gas-tight operation is possible by sealing the separation space off from the ambient air using inert gas

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Robust and extremely low maintenance Pneumatic free Highest rate of availability 5 - 12 mm strap Optimal strap guide at the strapping level 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Automatic Strap feed Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' OPTIONAL: Bundle compensator, side mounted Bundle stops, optional Bundle press, optional SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Table height steplessly adjustable Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Best cost / benefit ratio ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable EPP 'Exact Product Path' Conveyor speed steplessly adjustable For use with PP and PET strap GreenTech energy concept, low power consumption Intuitive touchscreen operating concept Machine movable MFT 'Mono-Frame-Technology' Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Table height steplessly adjustable Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Robust and extremely low maintenance Powerful Maximum flexibility & adaptability 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Wear-free, energy saving...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Variable strap width Optimal access Intrinsically safe machine, protection door-less concept Unique, the lateral strapper principle in the inline strapper 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection EPP 'Exact Product Path' ETS 'Easy to Service' - Maintenance while production Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption High-Speed-Kit, optional Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Robust and extremely low maintenance Optimal access All-round bundle guide Integrated safety concept ASLF 'Anti-Strap-Loss-Function' Constant strap control Pusher (bundle accelerator and bounce back function) Strap width 5 - 9 mm, adjustable Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp Additional operating buttons, opposite to terminal (Start/Stop/Emergency Stop) DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Upstream and downstream interlocks EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' OPTIONAL: Stacker adapter for existing stacker Bundle stops, no contact with bundle when clearing the bundle, with quick adjustment Bundle press Protection covers at feed and discharge side, hinged Lateral bundle guide, adjustable Side...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

With the flexo 700 e-com you are optimally equipped to meet the demands of film packaging for the e-commerce, mail order and logistics sectors. Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging for example, the flexo 700 e-com packs goods with a minimum use of film and automatically adjusts the film bags to the product‘s length as standard. To support the precise fitting of shipping bags, the flexo 700 e-com fit model also adjusts the bag size to the product's width so that the machines fully automatically adjust to varying product sizes during the packaging process. Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-LC automatic spindle capper is almost a universal capper, it is sutiable for capping screw caps, flip flop caps, spray caps, drops caps, metal caps, twist off caps. An automatic spindle capping machine is a device used to cap containers with screw-on caps. The machine works by placing the containers under a series of rotating spindles, which spin the caps onto the bottles or jars. The spindles are adjustable to fit different sizes and shapes of containers, and the speed can be adjusted for different production rates. The machine may also include features such as a cap sorter and feeder, a conveyor system to move the containers through the process, and controls to ensure proper torque and alignment of the caps. Automatic spindle capping machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and efficient capping is necessary for product safety and quality.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

STATEC BINDER GMBH

Austria

The SYSTEM-F, a fully automatic vertical form-fill-seal packaging machine, produces pillow bags and gusset bags with or without carrying handle and a filling weight between 5 kg and 50 kg from flat film. The System-F is particularly ideal for packaging powdery and moderately free-flowing products. Thanks to an adjustable format set, different package sizes can be produced. The format and/or production can be changed by one person in just a few minutes. This is made possible by a rotating magazine, which is installed directly on the machine and holds several format sets of different sizes ready at all times. The vertical FFS packaging machine impresses with its compact design and low space requirement. Further options allow this bagging machine to be adapted to a wide range of requirements.

Request for a quote

MICRO-EPSILON

Germany

The RTP 8302.T is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Request for a quote

MICRO-EPSILON

Germany

The RTP 8301.CT is based on laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The O-frame mechanics of the system dispose of a compensation frame which does not vary with temperature and which is used in order to avoid temperature fluctuations of the measuring frame using further sensors. The profilometer corresponds to the TIP 8301.CT regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

BEHN + BATES MASCHINENFABRIK GMBH & CO. KG

Germany

The continuous product flow from the filling chamber is ensured by the fluidization air quantities being adjustable to your product. For compact bag shapes the special BEHN + BATES filling de-aeration nozzle removes the air from the bag already during filling.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

An idle cut blade head with automatic cutting gap adjustment ensures that the Weber Slicer 604 has a high yield with minimum giveaway. The product throat can be adjusted automatically in height and width, and the fully automatic central loading unit ensures rapid product changes. Products up to 1,700 mm in length are fed in automatically and processed at up to 600 slices per minute. The shear bar and side limit stop can be configured by motor and with programme control. That allows the Weber Slicer 604 to guarantee a precise cut and placement of perfect slices continuously. Options: Slice folder Variogripper Idle cut blade head Separate blade drive Interleaver Portion designer

Request for a quote

FESSMANN GMBH UND CO KG

Germany

FESSMANN genuine spare parts are tried and tested in the process and correspond fully to the construction specifications. This pays off by highest availability. The high quality of the genuine FESSMANN spare parts used will lead to evenly high product quality. Timeconsuming adjustments are a thing of the past. Our service offers spare and wear parts for old and new systems. Our technical support is available to you with its competence and experience for the selection and consulting needed. We supply the required parts just in time for planned maintenance. We will gladly offer any support you need for maintenance and repairs. In the scope of service agreements, we also offer comprehensive and longterm spare parts concepts.

Request for a quoteResults for

Product adjustment - Import exportNumber of results

150 ProductsCountries

Company type

Category

- Jewellery and bijouterie (25)

- Conveyor belts (6)

- Bakery and confectionery industry - machinery and equipment (5)

- Labelling machines (5)

- Dosing pumps (4)

- Furnishings, cushioned (4)

- Machine tools, metal machining - parts and accessories (4)

- Agglomeration and emulsification machines for the food processing industry (3)

- Clothes, women's (3)

- Food Industry - Machines & Equipment (3)

- Bag filling machinery and equipment (2)

- Buckets and grabs, crane (2)

- Energy and raw materials - services to industry (2)

- Filtering equipment and supplies (2)

- Food Processing (2)

- Food industry - machinery and equipment (2)

- Food packaging (2)

- Furniture kits (2)

- Machine tools - metal machining (2)

- Oils, cooking - machinery and equipment (2)