- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press drives

Results for

Press drives - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work services are fully adapted to meet your facilities maintenance and safety needs : replacement and/or modification of walkways installation and/or modification of ventilation ducts manufacture and installation of floors and access doors on production lines welding of reinforcements on to machine frames modification of fabric drive systems, presses, cylinders and rollers modification of pneumatic and hydraulic control systems installation of conveyor lines mechanical protective equipment: grids, gratings, walkways and doors machine guarding: stainless steel, steel, etc. We guarantee a highly flexible and adaptable service, while meeting all of your production requirements and maintaining the configuration of your existing facilities.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture gears, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the overhaul of plants and machines (Retrofit).

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Table presses with different drive types are also suitable for use as a single workstation, as for use in punching systems. The advantage of these presses is that different tools can be used alternately. This is particularly economical in systems with which different articles with different punching patterns are produced.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 1992 Book back nipping press electr. drive hydraulic pressing Ref: GA240098A Please ask for price. We ship and install worldwide!

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Efficient positioning, assembly and handling of workpieces are key components in many manufacturing companies to meet growing cost pressures. Replacing pneumatic cylinders with electric linear drives can save up to 90 % of energy consumption. In addition, there are numerous advantages in motion control. IAI has the world's largest portfolio of electric actuators with 24 or 230 volt stepper or servo motors. The electric cylinders perform linear, rotary or gripping movements and are characterised by the uniquely compact design including motor and encoder as well the high quality. In addition to the standard version, electric cylinders are also available for cleanrooms and as IP-protected models for dusty or wet production environments.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LVD

Belgium

Effortlessly handle high tonnage, high production punching requirements with the V-Series. This full-featured 30-ton CNC punch press offers a flexible tool configuration, full sheet utilization and heavy-sheet carrying capacity. A large capacity turret provides the versatility of up to 120 fully indexable tools. The press drive system ensures the best power efficiency for higher tonnage applications. CNC programmable and relocatable work clamps allow full sheet utilization. Modular automation options add even more capacity and flexibility. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy reduction system minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute

Request for a quote

LVD

Belgium

The Dyna-Press is your perfect bending partner. The electric drive Dyna-Press delivers fast bending speeds of 25 mm per second to bend more parts per hour at a lower cost per part. Ideal for bending small and simple parts, its ergonomic design permits use in a standing or seated position. Add to this impressive production capabilities, easy to use control and compact size for a press brake that is fast, accurate and flexible. KEY FEATURES Compact design uses minimal floor space Easy transport with a standard forklift (except 40/15) Intuitive touch screen control Touch-B High repeat accuracy with 4-axis back gauge, 5-axis on Pro model PERFORMANCE-ENHANCING OPTIONS Extra gauge finger Safety sytem Air conditioning unit for electrical enclosure Vertical W-style or universal tooling CADMAN-B programming software MODELS Dyna-Press 24/12 Dyna-Press 40/15 Dyna-Press 40/15 Pro

Request for a quote

LVD

Belgium

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quote

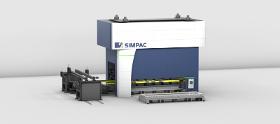

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quoteResults for

Press drives - Import exportNumber of results

11 ProductsCountries

Company type