- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press drives

Results for

Press drives - Import export

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture gears, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the overhaul of plants and machines (Retrofit).

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

Table presses with different drive types are also suitable for use as a single workstation, as for use in punching systems. The advantage of these presses is that different tools can be used alternately. This is particularly economical in systems with which different articles with different punching patterns are produced.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 1992 Book back nipping press electr. drive hydraulic pressing Ref: GA240098A Please ask for price. We ship and install worldwide!

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Efficient positioning, assembly and handling of workpieces are key components in many manufacturing companies to meet growing cost pressures. Replacing pneumatic cylinders with electric linear drives can save up to 90 % of energy consumption. In addition, there are numerous advantages in motion control. IAI has the world's largest portfolio of electric actuators with 24 or 230 volt stepper or servo motors. The electric cylinders perform linear, rotary or gripping movements and are characterised by the uniquely compact design including motor and encoder as well the high quality. In addition to the standard version, electric cylinders are also available for cleanrooms and as IP-protected models for dusty or wet production environments.

Request for a quote

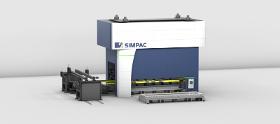

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Press drives - Import exportNumber of results

6 ProductsCountries

Company type