- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press brake

Results for

Press brake - Import export

PERGEL METAL

Turkey

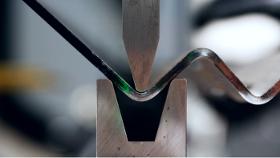

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

SINOP SMP

Czech Rep.

Die Bending with Press Brake Custom manufacturing as well as large volume production Software simulation of bending feasibility CNC programming of press brakes from office “Z” bend, flattened hems and radius bends Bending flexibility thanks to 6-axis backgauge Maximal bending length 3000 m, maximal sheet thickness 10 mm

Request for a quote

FUSED MACHINERY

Belgium

Excellent press brake with 650T bending force and 6200 bending length. This machine is in very good condition, immediately available and can be inspected under power. Extensive set of tooling available as well. More information on request.

Request for a quote

FUSED MACHINERY

Belgium

Bystronic press brake in very good condition. Can be inspected under power upon appointment. Immediately available. QUALITATIVE MACHINE BENEFITS: PRICE INCLUDES A BOX OF BENDING TOOLS, AS SHOWN IN THE FOTOS SPECIAL OPTIONS: BENDING SUPPORT, LED, SWING COUNTER, HOUR COUNTER

Request for a quote

METALUX

North Macedonia

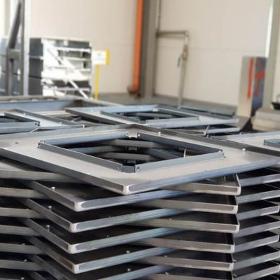

At our company, we take pride in offering CNC bending services that adhere to the highest standards of quality and precision, utilizing Press Brake's advanced bending technologies. We provide a wide range of CNC bending operations, tailored to meet each customer's specific preferences and needs. Quality is of paramount importance to us, and we are committed to maintaining this principle throughout all our CNC bending operations. To achieve exceptional results that meet our stringent quality standards, we rely on the industry's best-performing machines – Press Brake bending technologies. As your trusted OEM partner, we meet production demands with an agile approach and strict quality control, ensuring precision in every piece. Contact us now to discuss your needs and partner in shaping a brighter future for your sheet metal endeavors.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages through our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages through our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

OREMUS S.R.O.

Czech Rep.

The basis of efficient welding process is precision bending on modern machines. In our case, TruBend 8400 Press Brake offers a maximum bending width up to 4000 mm with pressure of a respectable 400 tons.

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

We offer sheet metal bending services up to 3m. We have high-performance press brakes with 7 axes and up to 160 tons of bending force.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

ESTIMET SP Z O.O.

Poland

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PPS (PRESSURE PROFILE SYSTEMS)

United Kingdom

The Industrial TactArray is a flat sensor that can capture and map pressure distribution in even the most extreme conditions. Constructed from high-quality Kapton or Polyimide, the Industrial TactArray can pressure distribution of up to 700 psi and in temperatures between -40° C and 200° C. This system is best suited for use in applications requiring tactile sensors that can withstand extremely high temperatures and pressures—like heat presses, brake pads, and nip rollers. Key Features High-resolution sensor arrays can measure pressure distribution at levels of up to 700 psi and retain performance characteristics in temperatures between -40° C and 200° C Real-time thermal compensation ensures accurate measurements even under changing temperature conditions Ultra-thin construction, 0.3 mm thick, and high-resolution sensing elements Can accommodate moderate flexing and bending Available in multiple sizes and configurations Chameleon Visualization Software included

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: - Sheet metal bending, - CNC tube/pipe bending, - And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: - Advanced press brakes with wipe dies to allow precise bending with minimal distortion. - Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. - Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. - Sheet bending up to 4000 mm. Capabilities for pipe bending: - Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

INOTECH MACHINING SRL

Romania

We perform various bending, edging, and forming procedures based on our client's needs and requierements: Sheet metal bending, CNC tube/pipe bending, And bending of elements obtained through other technological operations. Capabilities for metal sheet edging and bending: Advanced press brakes with wipe dies to allow precise bending with minimal distortion. Wide range of bend angles and radii: we can make sharp bends, complex curves, and intricate forms, tailored to your needs. Wide range of materials: steel, stainless steel, aluminum, alloys, and other sheet metals. Sheet bending up to 4000 mm. Capabilities for pipe bending: Our machines allow us to bend pipes up to Ø25 mm in diameter.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in manufacturing precise sheet metal components according to customer drawings and specifications, whether in steel, stainless steel, or aluminum. Our commitment to precision is ensured through the use of ACB sensors equipped in our bending and forming machines, allowing us to achieve highly efficient production repeatability. Additionally, we utilize 4 press brakes from TRUMPF company - models 7036, 3066, 5170, and 5085 - which enable us to bend sheets with a maximum width of 4250 mm. However, considering laser cutting capabilities, we bend sheets with a maximum width of 4000 mm, ensuring seamless integration of all production processes.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide sheet metal bending services. Our sheet bending is carried out with the help of edge presses with very high accuracy, long-series elements can be implemented through an automated device that supports the work of qualified operators. Material possibilities: • we have three press brakes that enable sheet bending at a length of 3000 mm. • The maximum bending length is 3000 mm • The maximum thickness of bending over a length of 1000mm – 5mm and 8mm • Pressure – 125 and 135 tons • With Laser head for cutting material at an angle – 3D Please send your inquiry to the following e-mail address: biuro@web-elektron.pl

Request for a quote

ELEKTRON SP. Z O.O.

Poland

“Bending” is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in plastic materials, most commonly sheet metal. Commonly used equipment includes box and cup brakes, press brakes, and other specialised machine presses. Typical products that are produced in this way are boxes, such as electrical enclosures and rectangular ducts. Bending sheet steel The combination of modern presses, advanced matrix, stamps and the experience of our employees provides excellent results in the form of professionally performed artistic processing of various sheets. We bend sheets quickly and extremely precisely, and thanks to the fact that the process is fully repeatable and automatic, we can undertake even very large orders. The maximum pressure of our machines is as much as 200 tons, thanks to which we can undertake artistic processing of materials with a thickness of 6 mm over a length of 3 meters.

Request for a quote

MIFA ALUMINIUM B.V.

Netherlands

Proper bending of aluminium and magnesium requires specific knowledge of the material. The phase in the process in which the material is bent is also crucial to the final result, right after pressing or only after hardening, for example. There are many techniques for bending, such as roll forming, press (brake) bending, swivel bending, deep drawing, stretch forming, and 3D bending.

Request for a quote

VOSSE SP. Z O.O.

Poland

We offer sheet metal bending on a CNC hydraulic press brake with a maximum pressure of 225 tons and a bending length of up to 4000 mm. Thanks to numerical control, we ensure very high repeatability of shapes. Sheet metal bending service is an indispensable process in the metal industry, allowing precise forming and shaping of sheet metal according to individual customer needs. We have a well-equipped warehouse of bending tools allowing us to make even the most complicated elements. Our advanced technology and the experience of our team guarantee the excellent quality of the bending workmanship and quick execution of orders.

Request for a quote

FUSED MACHINERY

Belgium

Bystronic press brake in good condition with a large set of tooling included (cf. pictures with description of tooling) Full technical specifications in attached document. More information on request

Request for a quote

FUSED MACHINERY

Belgium

Amada press brake in very good condition. Can be inspected under power. Immediately available! More information on request. Machine dimensions: Length: 5480mm Depth: 3000 mm Height: 3100mm Weight: 17250 kg

Request for a quote

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quoteResults for

Press brake - Import exportNumber of results

66 ProductsCountries

Category

- Bending - steels and metals (13)

- Brakes, servo-brakes and accessories (11)

- Bending machine tools (9)

- Laser - cutting and welding machines (4)

- Milling - steels and metals (4)

- Tempering, metals - machinery and installations (4)

- Cutting - steels and metals (3)

- Industrial sheet metal work (2)

- Metal industrial presses (2)

- Motor mechanics - hand tools, non power (2)

- Agricultural systems and equipment (1)

- Compactors and crushers (1)

- Construction, industrial - contractors (1)

- Finished Metal Products (1)

- Folding - steels and metals (1)

- Handling - Machines & Equipment (1)

- Magnetic equipment (1)

- Measurement - Equipment & Instruments (1)

- Punching machines, plastic (1)

- Sensors (1)