- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- powder coating process

Results for

Powder coating process - Import export

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Electrostatic powder coating, commonly known as powder coating, is a solvent-free surface coating technique. This method involves applying a layer of very fine powder particles to the surface, which are then baked to create a durable finish. The process starts with the electrostatic spraying of powder particles, which adhere to the material due to an electrostatic charge. After application, the coated product is heated in an oven, causing the powder to melt and chemically bond to the surface, creating a solid, protective layer.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Electrostatic powder coating, commonly known as powder coating, is a solvent-free surface coating technique. This method involves applying a layer of very fine powder particles to the surface, which are then baked to create a durable finish. The process starts with the electrostatic spraying of powder particles, which adhere to the material due to an electrostatic charge. After application, the coated product is heated in an oven, causing the powder to melt and chemically bond to the surface, creating a solid, protective layer.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Electrostatic powder coating, commonly known as powder coating, is a solvent-free surface coating technique. This method involves applying a layer of very fine powder particles to the surface, which are then baked to create a durable finish. The process starts with the electrostatic spraying of powder particles, which adhere to the material due to an electrostatic charge. After application, the coated product is heated in an oven, causing the powder to melt and chemically bond to the surface, creating a solid, protective layer.

Request for a quote

SC PROFINOX SRL

Romania

We provide professional powder coating services to achieve a smooth and pleasant finish on your products. The powder coating process ensures efficient and long-lasting surface coverage and costs are considerably optimized. The Profinox team recommends the use of powder coating if you want the surface of your product to have a different look from the one obtained through stainless steel sandblasting or mechanical finishing. You can choose powder coating both for a normal stainless steel painting process, and for elements obtained by laser cutting. The powder coating service performed by Profinox provides you with a high-performance and efficient technique. The process is carried out using a fine powder (a thermoplastic or thermosetting polymer) which is sprayed on and adheres electrostatically to the substrate. After the powder has been evenly distributed, the final step is to fix the paint. This is achieved by exposing the polymers to a temperature of about

Request for a quote

ERATEC

France

Metal fibre burners for new or existing epoxy powder coating installations Metal fibre burners and infra-red emitters for a more efficient, flexible and compact powder coating installation. POWDER COATING APPLICATIONS Choose the metal fibre burner right from the design stage: Pre/post-treatment, Paint drying, Teflon or ceramic coating, Continuous coating... IMPROVE YOUR FACILITIES The powder coating process: Preparing the substrate: cleaning, pre-heating Application of paint Gelling Polymerisation: hardening paint

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. It is the third generation of the globally accepted Datapaq EasyTrack brand successfully used in the powder and paint coating market by applicators and coating suppliers. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: Monitor and prove QA Optimize your powder coating oven performance and save energy costs Identify potential problems in your powder coating process and correct them quickly and efficiently Customize your EasyTrack3 system with ET3 temperature datalogger and a choice of thermal barriers, software and thermocouple range to meet your exact industrial coating process needs. For detailed information download the EasyTrack3 Brochure, EasyTrack3 Datasheet and EasyTrack3 3 Key Wins. EasyTrack Insight™ Software

Request for a quote

EASTMAN IMPEX SRL

Romania

Eastman offers powder coating services that provide durable, high-quality finishes for various metal products. Our powder coating process delivers excellent protection against corrosion, wear, and tear, with a range of colors and finishes available.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture products that not only perform exceptionally but also showcase a superior level of craftsmanship. We have expertise in a wide range of chemical and mechanical processes: - Electrostatic powder coating, - Liquid painting, - Anodizing (30-50 microns, black or grey), - Hard anodizing (30-50 microns, black or grey), - Zinc plating, - Yellow zinc chromate plating - Blackening (Black oxide coating) - cold or in oil, - Phosphating.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

Powder coating is a complicated process that requires a professional approach. From the very beginning, you should be very careful when choosing the right paint. The selection of appropriate measures ensures that the obtained surface meets all expectations and will last for a specified period of time. Among others, we can choose gloss, matte, or satin paints. Powder coating allows for both perfectly smooth and rough surfaces with various textures. We also have paints with increased resistance to various chemical substances or negative environmental conditions. In each case, we select the preparations and the method of work to obtain the maximum benefits for the client—in terms of functionality, aesthetics, and finances. An important aspect is also the fact that powder coating is a process that does not adversely affect the natural environment.

Request for a quote

VITAL PARTS LTD

United Kingdom

Our High Temperature Tapes are perfect for all kinds of masking uses during processes which regularly use a lot of heat, examples of these processes includes Powder Coating where powder is sprayed on as a coating before being baked on to an application for a permanent finish. Coming in a huge number of variations including Ultra high temperature & Low tack adhesives, you can rest assured that we have the best choice for you. As mainly film based products, these High Temperature Tapes are malleable and flexible meaning that they can be used for tricky areas where there are many sharp corners.Discs are also available which can be used to seal off and prevent small holes such as screw holes from becoming filled during the coating process. For our full selection of Powder Coating Tapes / High Temperature Tapes please visit our website using the link below. Free sample lengths are available on all our tapes meaning you can try before you buy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The automotive industry standard in thermal profiling of paint cure processes Silicone-free technology Multiple oven tests possible before returning to PC Process Pass/Fail at oven exit Up to 16 measurement locations in a single run Hard wired real-time data analysis from batch ovens Fully customizable and easy-to-use Insight analysis software Wide range of thermal barriers & thermocouples to suit your process needs

Request for a quote

SAMES KREMLIN

France

Instant and accurate result Easy and ready to use Reference equipment for powder development laboratories PERFORMANCE Accurate and quick measurement of the fluidity and of the ability of the powder to be fluidized Compact PRODUCTIVITY Helps determine the powder spraying parameters Quality management of powder batches SUSTAINABILITY Easy to clean Saves time for the comissioning of new powder paint facilities and/or new colors in the process AS 100 fluidimeter has been designed for the specific purpose of determining the capabilities of powder to be fluidized. In the powder coating process, the powder is transported and projected onto the part by suspending it in the air. However, powders react very differently to this suspension depending on their grain size, degree of humidity, formula, etc. The AS 100 fluidimeter demonstrates this behaviour and indicates immediately whether a powder is suitable for spraying purposes. It is a...

Request for a quote

ESENER AGRICULTURAL MACHINERY

Turkey

Boron Steel Suitable for Kverneland 14 mm - 10 mm Thickness Heat treatment process Powder coated

Request for a quote

ESENER AGRICULTURAL MACHINERY

Turkey

Boron Steel Suitable for Lemken 14 mm - 10 mm Thickness Heat treatment process Powder coated Code : 3364151 Code : 3364150

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Graphite-free lubricant for the forging of aluminium Temperature Range 130 °C to 380 °C Properties and Advantages • improved cleanliness of work environment (graphite-free) • reduced wear on tool surface due to the forming of an effective release film • good release of forgings • formation of a pressure resistant lubricating film • forgings can be painted and powder coated, downstream processes are trouble-free • alternative to graphite containing products

Request for a quote

PC REALIT

Slovakia

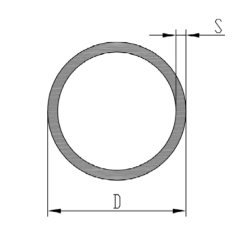

Round tubes from 8 х 2 mm to 120 х 10 mm are available for order. They all can be powder coated in any RAL colour, processed mechanically and anodized.

Request for a quote

PC REALIT

Slovakia

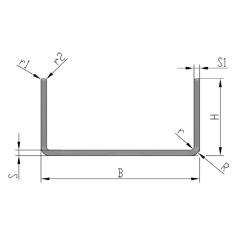

U-shaped channels with radius range from 21.8 х 23.8 х 2.1 mm to 175 х 80 х 8 mm. They can be powder coated in any RAL colour, processed mechanically and anodized.

Request for a quote

PC REALIT

Slovakia

U-shaped channels range from 10 х 10 х 1.5 mm to 125 х 55 х 6.5 mm. They can be powder coated in any RAL colour, processed mechanically and anodized.

Request for a quote

PC REALIT

Slovakia

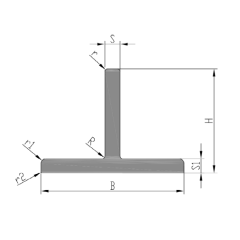

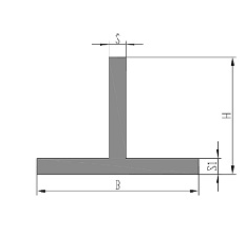

Aluminium T-Profiles with radius fall in the range from 32 х 12 х 2 х 2 mm to 65 х 94 х 10 х 15 mm. They all can be powder coated in any RAL colour, processed mechanically and anodized.

Request for a quote

PC REALIT

Slovakia

Aluminium T-Profiles fall in the range from 25 х 48 х 2 х 2 mm to 185 х 100 х 10 х 15 mm. They all can be powder coated in any RAL colour, processed mechanically and anodized.

Request for a quoteResults for

Powder coating process - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Construction Materials (9)

- Steels and metals - surface treatment and coating (5)

- Laser - cutting and welding machines (4)

- Anti-corrosion coatings (3)

- Coating machinery (3)

- Finishing of surfaces - machinery (3)

- Agricultural machines and accessories (2)

- Aluminium and aluminium alloys (2)

- Metal powders (2)

- Temperature sensing devices (2)

- Aluminium coatings (1)

- Cements, special (1)

- Cutting - steels and metals (1)

- Industrial paintings (1)

- Infrared tubes (1)

- Metalworking hand tools, non-power (1)

- Painting machinery and equipment (1)

- Paints and varnishes (1)

- Plastic coating - steels and metals (1)

- Stairs, metal (1)