- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- powder coating process

Results for

Powder coating process - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

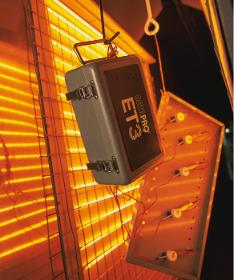

EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. It is the third generation of the globally accepted Datapaq EasyTrack brand successfully used in the powder and paint coating market by applicators and coating suppliers. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: Monitor and prove QA Optimize your powder coating oven performance and save energy costs Identify potential problems in your powder coating process and correct them quickly and efficiently Customize your EasyTrack3 system with ET3 temperature datalogger and a choice of thermal barriers, software and thermocouple range to meet your exact industrial coating process needs. For detailed information download the EasyTrack3 Brochure, EasyTrack3 Datasheet and EasyTrack3 3 Key Wins. EasyTrack Insight™ Software

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The automotive industry standard in thermal profiling of paint cure processes Silicone-free technology Multiple oven tests possible before returning to PC Process Pass/Fail at oven exit Up to 16 measurement locations in a single run Hard wired real-time data analysis from batch ovens Fully customizable and easy-to-use Insight analysis software Wide range of thermal barriers & thermocouples to suit your process needs

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ temperature profiling systems include high-accuracy industrial-strength data loggers, analysis software, thermal barriers, and thermocouples. EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: • Monitor and prove QA • Optimize your powder coating oven performance and save energy costs • Identify potential problems in your powder coating process and correct them quickly and efficiently The range of thermal barriers is designed to match different coating applications or operational needs. These provide dual protection confidence using microporous insulation and phase change technology and maintain logger temperatures at a level to guarantee the accuracy of the temperature measurements recorded.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LECHMANN ENGINEERING GMBH

Germany

Passivation is the chemical treatment of surfaces to increase corrosion protection with excellent conductivity. Positive for subsequent painting and powder coating processes, to reduce fingerprint sensitivity and to change the appearance (gloss, color). Maximum measurements 4000 x 1000 x 360 mm

Request for a quoteResults for

Powder coating process - Import exportNumber of results

7 ProductsCountries

Company type