- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning drives

Results for

Positioning drives - Import export

LENORD, BAUER & CO. GMBH

Germany

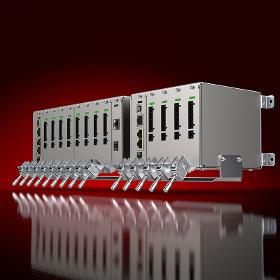

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Intelligent connection box in modular design • Two housing variants with 4/9 slots available • Module combination for control of up to 17 axes • Conveniently configurable via SeGMoSupport Tool

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Interface for controlling up to 5 positioning drives • Integrated power management • Straightforward commissioning of the SeGMoPositioning • Depending on the design either with cULus component recognition or cULus listing • Support Tool for advanced commissioning and configuration

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

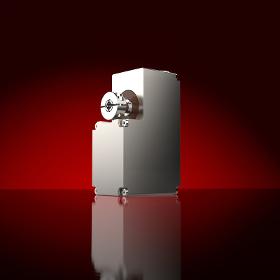

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive with through hollow shaft • Batteryfree multiturn absolute encoder • Aluminium housing • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive suitable for a wide range of applications in various industrial areas • Batteryfree multiturn absolute encoder • High dynamics • Optional use with the SeGMoBox or as a standalone device • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive for installation situations with little space • Monitoring of important system parameters ensures reliable operation (overload protection) • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree due to sealedforlife lubrication • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Conventional thermometers measure the temperature by means of length or volume change of a material, and are only suitable as display instrument. Temperature sensors from Lenord+Bauer use resistance thermometers that feature an almost temperaturelinear r

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

The fully ULcertified positioning system from Lenord+Bauer consists of three individual elements that can be flexibly combined as required positioning drives by the name of SeGMo, the decentralised SeGMoBox control unit for flexible fieldbus integration and the associated hybrid cable solution, including connectors, that is suitable for use with drag chains. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. Lenord+Bauer also offers these for standalone use. With nominal torques of up to 15 Nm, they cover the capacity range typical for secondary axes. Integrate the drives directly into your control system with the function blocks. Alternatively, you can automate up to 17 secondary axes using the decentral SeGMoBox. The box handles the power management for the connected drives and concentrates the interaction with the system control.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

LALK GMBH &CO. KG

Germany

The powerful and lightweight motor paired with the compactness of the machine allows for an excellent weight-to-performance ratio. The integrated gearbox and position of the drive wheels provide a cutting depth of up to 122mm. Starting the machine is also very easy due to its design. Because of the combination of Poly-V belt, maintenance-free DuraStarter, and efficient air filter system the maintenance intervals are extended. The cutting arm ensures a consistent and tight cut whether on a wall or floor. All in all, a great choice for a compact and highly powerful dry-cut saw.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Hydrostatic bearings are characterized by practically frictionless movement. The corresponding linear guides are free from stick-slip effects and there is practically no wear on the guides. Gases (mostly air) or liquids (mostly oil) can be used as the carrying medium. Air-bearing guides are ideal, for example, for clean room applications or at high sliding speeds. If oil is used as the carrying medium, higher carrying forces can be achieved with the same size and better damping properties. Various designs are available, which can be customized at any time to meet special requirements in terms of installation space, load capacity, guide length / table diameter, drive type, position measuring system, etc.

Request for a quoteLT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Hydrostatic bearings are characterized by practically frictionless movement. The corresponding linear guides are free from stick-slip effects and there is practically no wear on the guides. Gases (mostly air) or liquids (mostly oil) can be used as the carrying medium. Air-bearing guides are ideal, for example, for clean room applications or at high sliding speeds. If oil is used as the carrying medium, higher carrying forces can be achieved with the same size and better damping properties. Various designs are available, which can be customized at any time to meet special requirements in terms of installation space, load capacity, guide length / table diameter, drive type, position measuring system, etc.

Request for a quote

SIKO GMBH

Germany

High-resolution encoder MSA213C for drive technology The requirements for sensors used for position detection in automation and drive technology increase with the complexity and performance of the associated machines and systems. A new MSA213C high-resolution absolute sensor from SIKO is a perfect solution. It not only supplies the absolute position at any time without referencing and without requiring a backup battery, but thanks to its small design and many different interfaces, it can also be integrated into the system and control environment with very little effort.

Request for a quote

EC PLAZA

South Korea

The camshaft sensor enables the engine control to determine the exact position of the crankshaft drive. This information is required to calculate the ignition point and injection point, among other things. New auto spare part Original part OE Part number 39350-25010 OE Part name SENSOR-CAMSHAFT POSITION Hyundai GRANDEUR, NF SONATA

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Kendrion offers for its CODESYS-based controllers a library with blocks for motion control functions according to PLCopen for various drive controllers. The Kuhnke Motion Control library provides a wide range of function blocks for parameterization, positioning and diagnostics of the drive. The blocks are simple and intuitive to use and support in all phases of the workflow e.g. during programming, commissioning, diagnostics and maintenance. The motion task in the control system can thus be programmed simply, quickly and thus economically. A drive with only a few lines of code is put into operation via the corresponding visualization templates. The library supports drive controllers from various well-known companies and supplies a wide range of standardized functions. The communication between the drives and the control can take place via various fieldbuses such as EtherCAT®, CAN, Modbus or RS-485. Features

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

—>Highly flexible transfer element with high torsional elasticity —>High torsional vibration and shock load damping capability —>Compensation of misalignments and easy positioning of the drive and drive train possible —>Direct connection to flywheels according to specification Ready-to-install custom solution —>Diverse designs achievable with modular construction —>Compensation of axial, radial and angular displacements —>Radial (dis)assembly of the coupling element —>Maintenance-free —>Extended range of application due to Atex certification in accordance with Directive 2014/34/EU

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

GRW - Geared agitator with worm geared drive The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive. The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals. Upon request, we supply the GRW series with frequency controlled drives.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRK series geared agitator equipped with a helical bevel geared drive with reinforced bearing can be used for a wide range of applications due to its low installation height. This ow installation height can be achieved thanks to the horizontal position of the drive. The agitator shaft of the GRK series is directly mounted in the hollow shaft of the gear and, upon request, this agitator shaft can be divided by flanged coupling. After assembly of the mixer, the agitator shafts are balanced for concentric run. The GRK series features shaft lengths of up to 6,000 mm and drive ratings of up to 75.0 kW. It has a standard output speed of 1 to 250 rpm. According to the specific mixing task, the GRK series can be supplied with matching mixing elements and various seals. Upon request, we supply the GRK series with frequency controlled drives that have drive ratings of up to 7.5 kW. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive. The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals. Upon request, we supply the GRW series with frequency controlled drives.

Request for a quote

AVM AUTOMATION

France

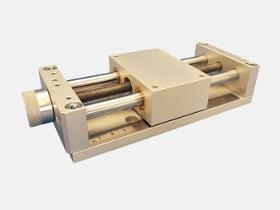

Manual positioning table drived by metric fine thread screw (pitch 1 - 1,25 mm). Actuated by grip knob. Guided by 2 rods on bronze bearings. Robust and economical table. Interchangeable with the 309B range. Options : Positioning indicator Position clamping Base plate (with or without ruler) Assembly in XY or YZ table

Request for a quote

AVM AUTOMATION

France

Economical manual positioning table drived by leadscrew. Actuated by grip knob. Guided by 2 rods on bronze bearings. Using of economical manual tables Acting is done by a grip knob supplied with the table. Maxi stroke is 100 mm for size 0, and 200 mm for sizes 1 and 2. Any nonstandard intermediate stroke can be produced. The locking in position is done on the trapezoidal screw, either in position B1 (above the front plate) or in position B2 (at the end of the end plate) depending on the access and the space available. The position is visualized by a mechanical indicator or by ruler on the base plate. The fixing on the frame is done by the 2 end plates (laminated holes) or by the end plate in « Z axis » version for vertical applications. The positioning accuracy of economical manual tables The axial positioning accuracy of these tables is <0.20 mm (in practice 0.05 to 0.15 mm), because the axial play is largely eliminated after locking in position

Request for a quote

AVM AUTOMATION

France

Small manual positioning table Driving by metric screw M6x1 Guided by 2 rods in steel Precision and compactness of this small manual table It is the smallest manual table in our range (width 54 mm / height 27,5 mm). Screw step is 1 mm per round and axial precision of these tables is <0.05 mm after locking in position (<0,10 mm before locking in position). Locking in position is done on the transmission screw, either at the top of the bearing (position B1) or at the end of the table (position B2). Grip knob, position indicator and maxi stroke The shaft outlet is threaded to screw in the grip knob with or without a position indicator (or the handwheel, but it can’t be used with an indicator). The maxi stroke is 100 mm, and any intermediate stroke can be produced. Compact lifting table, miniature cross table and base plate A version « Z axis » allows to fix the table only by its end plate. It can be fixed directly on the carriage of another table for a YZ mounting.

Request for a quote

AVM AUTOMATION

France

Manual positioning table drived by lead screw Guided by 2 rods on bronze bearings or ball bushings Precision manual tables The guidance is ensured by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without play. The guide length of long body tables (309L/M) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking. Manual crossed tables XY or YZ For the creation of XY crossed table, the tables are mounted one on the other directly by the body (long body version only) with the option 308922 * making smooth holes in the body of a table. To combine 2 tables in YZ, it is preferable to use a lifting table for the Z axis, mounted by its end on the body of the horizontal table.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

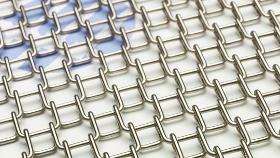

Compact-Grid™ stainless steel conveyor belt is engineered to offer superior support for small products. The unique grid pattern provides 70% open area which makes it easy-to-clean and offers exceptional air and liquid flow-through properties for heating, cooling and coating operations. Compact-Grid’s no-slip positive drive provides the highest standard in belt tracking, which means the belt will run straight and true even under heavy loads. Joining Compact-Grid is fast and simple, making belt installation easy.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Compact-Grid® stainless steel conveyor belt is engineered to offer superior support for small products. The unique grid pattern provides 70% open area which makes it easy-to-clean and offers exceptional air and liquid flow-through properties for heating, cooling and coating operations. Compact-Grid’s no-slip positive drive provides the highest standard in belt tracking, which means the belt will run straight and true even under heavy loads. Joining Compact-Grid® is fast and simple, making belt installation easy.

Request for a quote

MAFDEL

France

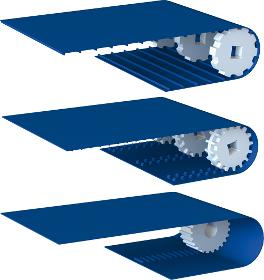

Positive drive conveyor belts DEL/SYNC associate conveyance and synchronous drive with extreme precision. It offers an excellent guidance and precise positioning of the transported products. Made in polyurethane, DEL/SYNC conveyor belt is reinforced by aramid reinforcements that eliminate elongation. Both the upper and lower surfaces are easy to clean and contribute to improve the hygiene level.

Request for a quote

MAFDEL

France

Positively driven conveyor belts POSITIVEBELT offer an exceptional guidance thanks to the dual rows of teeth. The perfectly smooth upper face facilitates the cleaning and helps maintaining a high hygiene level. Compliant with the strictest standards, the POSITIVEBELT is also resistant to abrasion and cut. The POSITIVEBELT can be equipped with accessories (cleats, sidewalls, scrapers...) to meet the conveyance constraints.

Request for a quote

MAFDEL

France

Positive drive conveyor belts associate advantages of modular belts and monomaterial conveyor belts without their disadvantages. The hygiene level is thus optimized, and the risks of slippage are eliminated. MAFDEL proposes 3 positively driven conveyor belts: - DEL/DRIVE: The alternative ideal to conventional modular belts - POSITIVEBELT: The self-tracking positive belt - DEL/SYNC: Fully synchronous drive The positive drive conveyor belts can be equipped with accessories (cleats, sidewalls…) and are adapted to many conveyor configurations: inclined, swan-necked, bidirectional, troughed conveyor… The whole range is compliant with the strictest hygiene standard, and contribute to meet the needs of HACCP requirements.

Request for a quoteResults for

Positioning drives - Import exportNumber of results

84 ProductsCountries

Category

- Servomechanisms (17)

- Welding robots (9)

- Driveshafts and micro-motors - electric (7)

- Measurement - Equipment & Instruments (6)

- Automation - systems and equipment (5)

- Conveyor belts (5)

- Bearings, ball (3)

- Sensors (3)

- Bearings - ball, needle and roller (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Industrial robots (2)

- Car body repair shops - services (1)

- Clutches (1)

- Conveyor systems (1)

- Cooling tanks (1)

- Electrical & Electronic Components (1)

- Electronics - ships (1)

- Gas turbines (1)

- Grids, gratings and wire mesh (1)

- Joints, pneumatic (1)