- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning drives

Results for

Positioning drives - Import export

NORELEM FRANCE

France

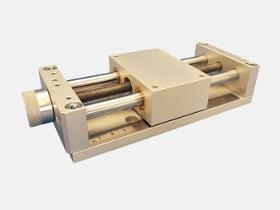

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

AVM AUTOMATION

France

Manual positioning table drived by metric fine thread screw (pitch 1 - 1,25 mm). Actuated by grip knob. Guided by 2 rods on bronze bearings. Robust and economical table. Interchangeable with the 309B range. Options : Positioning indicator Position clamping Base plate (with or without ruler) Assembly in XY or YZ table

Request for a quote

AVM AUTOMATION

France

Economical manual positioning table drived by leadscrew. Actuated by grip knob. Guided by 2 rods on bronze bearings. Using of economical manual tables Acting is done by a grip knob supplied with the table. Maxi stroke is 100 mm for size 0, and 200 mm for sizes 1 and 2. Any nonstandard intermediate stroke can be produced. The locking in position is done on the trapezoidal screw, either in position B1 (above the front plate) or in position B2 (at the end of the end plate) depending on the access and the space available. The position is visualized by a mechanical indicator or by ruler on the base plate. The fixing on the frame is done by the 2 end plates (laminated holes) or by the end plate in « Z axis » version for vertical applications. The positioning accuracy of economical manual tables The axial positioning accuracy of these tables is <0.20 mm (in practice 0.05 to 0.15 mm), because the axial play is largely eliminated after locking in position

Request for a quote

AVM AUTOMATION

France

Small manual positioning table Driving by metric screw M6x1 Guided by 2 rods in steel Precision and compactness of this small manual table It is the smallest manual table in our range (width 54 mm / height 27,5 mm). Screw step is 1 mm per round and axial precision of these tables is <0.05 mm after locking in position (<0,10 mm before locking in position). Locking in position is done on the transmission screw, either at the top of the bearing (position B1) or at the end of the table (position B2). Grip knob, position indicator and maxi stroke The shaft outlet is threaded to screw in the grip knob with or without a position indicator (or the handwheel, but it can’t be used with an indicator). The maxi stroke is 100 mm, and any intermediate stroke can be produced. Compact lifting table, miniature cross table and base plate A version « Z axis » allows to fix the table only by its end plate. It can be fixed directly on the carriage of another table for a YZ mounting.

Request for a quote

AVM AUTOMATION

France

Manual positioning table drived by lead screw Guided by 2 rods on bronze bearings or ball bushings Precision manual tables The guidance is ensured by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without play. The guide length of long body tables (309L/M) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking. Manual crossed tables XY or YZ For the creation of XY crossed table, the tables are mounted one on the other directly by the body (long body version only) with the option 308922 * making smooth holes in the body of a table. To combine 2 tables in YZ, it is preferable to use a lifting table for the Z axis, mounted by its end on the body of the horizontal table.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAFDEL

France

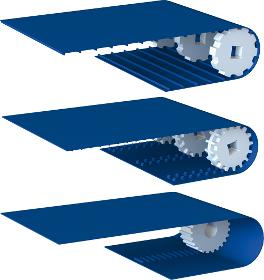

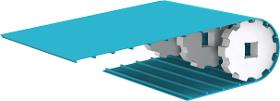

Positively driven conveyor belts POSITIVEBELT offer an exceptional guidance thanks to the dual rows of teeth. The perfectly smooth upper face facilitates the cleaning and helps maintaining a high hygiene level. Compliant with the strictest standards, the POSITIVEBELT is also resistant to abrasion and cut. The POSITIVEBELT can be equipped with accessories (cleats, sidewalls, scrapers...) to meet the conveyance constraints.

Request for a quote

MAFDEL

France

Positive drive conveyor belts associate advantages of modular belts and monomaterial conveyor belts without their disadvantages. The hygiene level is thus optimized, and the risks of slippage are eliminated. MAFDEL proposes 3 positively driven conveyor belts: - DEL/DRIVE: The alternative ideal to conventional modular belts - POSITIVEBELT: The self-tracking positive belt - DEL/SYNC: Fully synchronous drive The positive drive conveyor belts can be equipped with accessories (cleats, sidewalls…) and are adapted to many conveyor configurations: inclined, swan-necked, bidirectional, troughed conveyor… The whole range is compliant with the strictest hygiene standard, and contribute to meet the needs of HACCP requirements.

Request for a quote

MAFDEL

France

The range DEL/DRIVE conveyor belt is the ideal alternative to conventional modular belts: it can replace a modular belt without any modifications. To meet all needs, DEL/DRIVE range is composed by several versions: - DEL/DRIVE 50: Made in polyurethane, it is both flexible and resistant and has high tensile strength. - DEL/DRIVE 25: The pitch of 25mm allows using smaller diameter of sprockets. The space required is thus reduced, and the transfer of the transported products is facilitated. - DEL/DRIVE 50H: Made in polyester elastomer, it is recommended for the transport of medium to heavy-weight - DEL/DRIVE 50AM: It benefits of an antimicrobial treatment which improves the hygiene level. - DEL/DRIVE 50AMEM: It also benefits of an antimicrobial treatment and has an embossed upper face that reduced the adherence of transported products. - DEL/DRIVE 50EMLT: It works in very low ambient temperatures and its embossed upper face facilitates the conveyance of frozen poducts.

Request for a quoteResults for

Positioning drives - Import exportNumber of results

9 ProductsCountries