- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- crushers

Results for

Crushers - Import export

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Welded structure from steel sheets. They are mounted on the shaft in the housing two discs to which clamp hammers are attached. Crusher inside it is lined with carpet, in the lower part with grates, and a gap between them allows the crushed material to move downwards at an appropriate level granulation. The hammers, grate and carpets are made of material abrasion resistant. The hammers on the discs are mounted oscillatingly.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

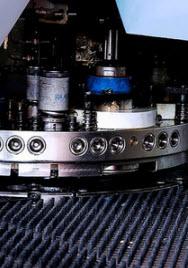

Reduce low volume turnings to flowable chips- at the source. Continuous low volume metal scrap reduction at the source. Metal crushers are the economical solution for processing stringy and bulky turnings into flowable chips. This piece can be integrated into existing equipment or free-standing. PRAB’s automated scrap removal systems are designed for volume reduction of metal turnings. The comprehensive focus on chip processing provides metalworking companies with an automated, safe and cost-effective way to process all kinds of metal scrap. The first step in this operation is to create flowable chips from metal turnings with scrap handling equipment. The Horizontal Axis Crusher processes low volumes of stringy and bulky metal turnings. This scrap metal recycling equipment is typically mounted on a stand or heavy-duty cart which fits on the discharge of the conveyor off the machining center

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial Size Reduction Experience seamless material processing with Lumpmaster, the ultimate low-speed, high-torque lump breaker. Clumping prevention begins when material enters the LumpMaster through the opening in the top. Pieces of material too large to pass through the rotating shaft pins and the stationary combing bars are crushed as the shaft weldments rotate. The material continues to be crushed until it is small enough to pass through. Designed for compact, inline installation in various industrial environments, our durable Lumpmaster unit ensures uniform size reduction. Choose from 12”, 18″, or 24” models in carbon or stainless steel for your specific application.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

During metal scrap processing, conveyance systems using augers or steel belts frequently fail to consistently move bushy bundles of metal scrap because the augers and steel belts are unable to grab hold of the stringy wads. This limitation causes the bundles to bounce around the in-feed hopper until an operator manually breaks them up, or forces the bundle up the conveyor. This practice is both inefficient and unsafe. The PRAB Bundle Breaker installs in a conveyor’s in-feed hopper, where dual rotating cylinders agitate the material, tearing stringy wads of chips, turnings, and bundles apart to allow for effective processing in downstream equipment. The PRAB Bundle Breaker may be added to an existing conveyor or incorporated into a new PRAB metal scrap processing system.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial metal shredders for reducing light to moderate wads of metal turnings to flowable chips. Reduce volumes by shredding metal turnings into flowable chips for higher value in scrap metal recycling. PRAB’s industrial metal shredders are a safe and cost-effective way to process all types of steel turnings and other metalworking scrap. They use less space for storage prior to scrap metal recycling and provide safer work areas. Available as a system integrated unit for use with chip processing/scrap removal equipment or as a stand-alone unit for volume reduction at the source. The development of automated scrap removal systems begins with reducing the volume of metal turnings. Milling, turning, screw machining, and swiss machining operations all produce waste that varies in size, length, hardness, and configuration depending on the tool, operation, and material characteristics.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce metal turnings and bulky wads into shovel-grade chips with a vertical axis crusher. The PRAB vertical axis metal crusher provides continuous, positive feed operation for high volume scrap reduction on the plant floor. Nested wads of metal turnings take up valuable floor space, are a safety hazard and have reduced scrap metal recycling value due to added processing costs. The PRAB vertical axis crusher is one of the most effective pieces of scrap metal processing equipment for quickly and safely creating flowable, thumbnail-sized chips from wads of turnings. Turnings are fed into the crusher’s feed hopper either by self-dumping hoppers, a plant-wide conveyor system, or an automated dump system with standard barrels or chip carts. The crusher’s feed hopper housing -with fixed cast cutters and rotating cutter- then directs the material down into the fixed and rotating cutter rings, where the material is reduced to flowable thumbnail sized chips.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Process loose metal turnings into flowable chips. Scrap metal recycling system couples volume reduction with fluid separation to produce dry chips and reclaim 99% of valuable coolants and cutting oils. The ideal solution for scrap metal consisting of flowable chips and loose turnings

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce volumes of large bundles and stringy turnings. This scrap metal equipment delivers dry, shovel-grade chips and reclaims up to 99% of valuable coolants and cutting oils

Request for a quote

TARET

Poland

Taret's offer also includes a snow plow that can be mounted both at the front and at the rear of the tractor. The plow has a working width of 2.5 meters. The plow can be rotated and set in 3 working positions, both at the front and at the rear.

Request for a quote

TARET

Poland

The product perfectly eliminates physical effort during all kinds of work on the farm, such as: moving loose materials, transporting seed material or collecting stones from fields. The box is equipped with a manual quick unloading system, a popular tipper.

Request for a quote

TARET

Poland

The roller crusher is designed for crushing and grinding grains of cereals into ground grain in order to increase digestibility and for more thorough mixing with other feeds. Before crushing, the grain should be pre- cleaned, it must not contain stones, screws, nails and other items.

Request for a quote

TARET

Poland

Disc harrows are characterized by a simple, durable, proven design in difficult conditions. They are offered in several working widths.

Request for a quote

TARET

Poland

Cultivators with spring tines are used to loosen, crush and mix the surface layer of the soil. They can be used to pull out weeds and cultivate stubble. The aggregate with a string roller can be used for pre-sowing crops for cereals, maize or potatoes.

Request for a quote

TARET

Poland

Plow intended is for mini tractors and tractors with power from 10 KM such as: Kubota, Yanmar, Iseki, DongFeng, Kyoti Jinma,Xingtai, Mitsubishi and others. The design of the plow is reinforced, what allows for plowing in clayey soils and difficult soils

Request for a quote

TARET

Poland

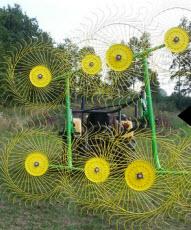

Our rake has both eight and four wheels intended for individual farms for tedding and raking grass and other plants dried for hay. The product is available only on request.

Request for a quote

TARET

Poland

The machine is designed for individual farms for tedding and raking grasses and other haydried plants. The product is available in three versions: three, four and five wheeled.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TARET

Poland

Cutting width: 100 cm Number of knives: 6 Weight of the mower: 135 kg Mower attachment: Three-point linkage Power demand in kW: 18.4 kW (25km) Drive: PTO 540 rpm

Request for a quote

TARET

Poland

The two-row suspended seedling planter is designed for planting all kinds of non-potted seedlings with a height of 6 to 20 cm, in field crops. The seedlings can be planted in any chosen row spacing, starting from 30 cm. In the vegetable industry, the planter is used to plant cabbage, lettuce, tomatoes, celery, peppers and strawberries. In horticulture and forestry, it is used to establish nurseries of roses, shrubs, spruces and pine trees.

Request for a quote

TARET

Poland

Vibrating potato diggers are used on farms growing potatoes for their own needs. These are crops where there is no need for specialized crops potato harvesters.

Request for a quote

TARET

Poland

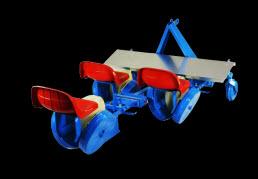

One-row and two-row automatic potato planters are suspended on the tractor's three-point linkage The machine performs all work related to planting potatoes in one work cycle: it plows up furrows, plants potatoes, covers them with soil, forming ridges. Single-row planters should cooperate with a tractor of the class 1N, with a three-point linkage of the category I.

Request for a quote

TARET

Poland

The digger is designed for digging up potatoes and onions. The product is dedicated to work in soils with low weed infestation and stone formation. It achieves very good results in soils with medium moisture. He digs up potatoes from one ridge, cleans and leaves them in the dug-out ridge.

Request for a quote

TARET

Poland

A single-furrow plow is a light device for stubble cultivation, which is perfectly matched to tractors with less power. The plow folds the furrows to one side in the right direction, which allows execution specialized bed plowing with separate tracks travel in the opposite direction.

Request for a quote

TARET

Poland

Our automatic powder coating plant offers comprehensive and professional services for companies. We guarantee a solid and fair approach to each task. As befits reliable powder paint shops, we use equipment that allows us to obtain a precisely dry-painted surface. When providing services in our powder coating plant, we only use materials from reputable manufacturers. We offer paints based on the RAL system and many others, which together provide a wide range of colors. It is possible to obtain various finishes and structures of elements - smooth, fine structure, coarse structure, gloss or matte. We adjust all details to the individual needs of our clients.

Request for a quote

TARET

Poland

We conduct welding processes in carbon dioxide and argon gas shields. We weld inox steel using the TIG method. We also weld aluminum alloys and non-ferrous metals. We perform spot welding on spot, table and forceps welders. We have about 10 welding machines in our machine park We have approximately 20 MIG-MAG and 5 TIG stations for welding. In our machine park we also have 3 welding robots from Yaskawa and one from ABB. Our largest robot has a working area of 6x2.5 meters.

Request for a quote

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quoteResults for

Crushers - Import exportNumber of results

33 ProductsCompany type