- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pellet production lines

Results for

Pellet production lines - Import export

COMERC SP. Z O.O.

Poland

We design, manufacture, build, train and service The pellet production lines designed and installed by our company offer capacities ranging from 2 t/h to 20 t/h. The capacity achieved naturally depends on the number and power of the machines and equipment comprising the production line. Pellet production lines – the offer: •design (technical conceptual design, formal arrangements, technical documentation, manuals, cost calculation), •supply (machines, devices, measuring and control apparatus, control cabinets, and all installation materials), •installation (machines, devices, control cabinets, measurement, control and feed wiring, post-installation testing, acceptance measurements), •software (controllers, operator panels, visualisation and control systems), •commissioning (machines, devices, control cabinets, control and power installations), •training process operators, programmers and IT technicians and technical human resources, •service within the warranty period and beyon

Request for a quote

ERO PROJEKT D.O.O.

Slovenia

We also have our own production program, which covers the areas of telecommunications, railways, post office and dedicated industries. We have also developed a pellet production line.

Request for a quote

DURO DAKOVIC STROJNA OBRADA D.O.O.

Croatia

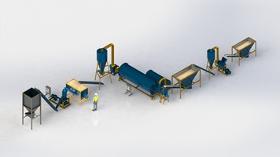

Our company has been producing a pelleting line for pellet production from biomass. Pellet mill capacity and complete lines is 500 kg/h of wood pellets and 1000 kg/h of Biomass. Pallet lines are suitable for sawmills, furniture manufacturers, farms and others. Below you will find the layout of pellet lines, which are designed according to specific customer requirements depending on their production areas

Request for a quote

CHAOYANG RUNXING HEAVY MACHINERY MANUFACTURING CO. LTD

Turkey

Chaoyang runxing heavy machinery Manufacturing Co.,ltd are engaging on manufacturing heavy machinery equipment and spare parts for almost 40 years, we could provide cement production line, rotary kiln, cement mill, ball mill, raw mill, slag mill, cement grinding equipment, preheating equipment, laterite nickel rotary kiln, oxidized pellet production line, air swept coal mill, mining mill, autogenous mill, semi-autogenous mill, rolling machine, vertical mill, crushing equipment, cooling machine, drying equipment, fluidized bed furnace, compound fertilizer equipment, blending machine, feeding machine. We passed the certification of ISO9000. Please contact us for more details. zoeyguo369@gmail.com wechat:chaoyangrunxing

Request for a quote

SEQUOIA HOLZ GMBH

Germany

We are certified Manufacturer of wood pellets according to the ENplus® A1 Standard. When buying chopped Wood pellets & firewood, you get high-quality and eco-friendly products, which provide high heating emission (due to drying of moisture of 8-12%), do not smoke, do not pollute the environment and prolong the service life of heating plants. Diameter: 6 mm Energy content: about 4,9 кВтг/кг Moisture: 8-10% Ash content: ≤ 0,7% Raw material: 100% wood Gross CV (d): 4977 kcal/kg Certificates: ENplus A1 The price for chopped firewood and pellets which meet the quality standards is based on the cost for fuel production without hidden charges. Cost-effective delivery to partners Delivery in Germany and anywhere in Europe is carried out by our partners — carrier companies, which offer several delivery options Certified production The fuel pellets production lines are equipped with modern domestic systems, certified by European standard

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The chili selecting production line is the latest production line developed by our company. Its main function is to improve the quality of chilis through sorting and grading. This production line has a reasonable design, large production capacity, strong practicality, good selection effect, and other characteristics.

Request for a quote

SMARTMAK

Turkey

Tomato sauce production line starts from Fresh tomato to final packaged product. Tomatoes undergo several processes including washing, sorting, crushing, concentrating, filling and packaging according to customer's demands.

Request for a quote

AUTOMATED PRODUCTION LTD

United Kingdom

From fullly automated production lines to simple poke yoke devices for quality assurance, we have the knowledge and experience to meet your specific needs and requirements. No project is too big or too small for our engineers. We build all machines in-house. APL has been improving production processes for manufacturing companies for 30 years.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

Based on years of experience in oilseed pressing and processing, Yongming machinery has designed two processes: cold pressing and hot pressing. The cold pressing process can retain active nutrients, reduce the color of crude oil, and produce oil with a strong flavor when using the hot pressing process to meet the needs of different users. Moreover, the oil yield is high and the production cost is low. The entire production line is equipped with advanced cleaning, pressing technology, and refining technology while paying attention to energy conservation and environmental protection, reducing emissions, saving costs, and maximizing corporate profits. Given the environmental protection and workshop hygiene requirements of modern industry, this production line is equipped with a complete dust removal system, and all connections for material transportation are equipped with suction to meet production and environmental protection requirements.

Request for a quoteResults for

Pellet production lines - Import exportNumber of results

10 ProductsCompany type