- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire machining

Results for

Wire machining - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

In addition to our extensive range of bright steel, we manufacture all standard machining steel wires in various designs at our sites in Schwerte, Iserlohn and Nedri Industriedraht (Hamm). according to DIN EN 10263 part 2-4 according to DIN EN 10267 Special analyses on request

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AI 01 E is a stripping machine driven by an electric motor. Exact stripping of different insulated wires up to an outer diameter of 5 mm is possible. Adjustments are very easy to handle with an adjustmend knob. In addition a special funnel to infeed thin wires is also delivered. Special: An integrated battery allows up to 10,000 working cycles when fully charged and without external power supply.

Request for a quote

WIB SA

Switzerland

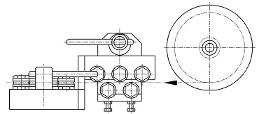

The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the ground “V” groove on the outer ring is machined and positioned precisely relative to the internal geometry. WIB only produces straightener roller bearings produced in this fashion, while many other producers machine the outer wire guide groove after assembly

Request for a quote

PERGEL METAL

Turkey

Today, electrical and wired devices are the most needed products. Computers, televisions, internet, chargers or many machines are used wired. In order for the cables to have a long service life and be used without problems, they must be very well maintained. For this, there are also cable regulators. These regulators prevent and protect the cable from damage. In this way, there are no situations such as breaking, breaking, crushing or bending. It is one of the most preferred materials.

Request for a quote

FERPLAST SNC

Italy

The tying machine with wire FP ASTRO-C2 is suited to the binding of small-sized products, particularly delicate, of variable size. By simply tying the elastic thread FP ASTRO-C2 ensures bundles of flowers or vegetable bundles and packs of small industrial products such as pens and hoses, ligation of labels on cans (preserves, mustards, jams, pickles), small packages of labels, stickers and many more. The minimum diameter of a beam is 7 mm. The machine is conceived and designed to also be used in automatic lines, on request can be realized versions in vertical or upside down. The FP ASTRO-C2 has renewed mechanism FEED IN which ensures a high speed and accurate ligation of the product. This tying machine is also equipped with a delivery system (KRS) that controls the release of the node. In this way the product is associated with the minimum voltage so as not to be damaged.

Request for a quote

FERPLAST SNC

Italy

MINI TWIST 140-160 CABLE - SEALING MACHINES WITH TWIST BAND Twisting manual machine, designed and built to tie different kinds of product, with a twistband wire. It is mode in varnished steel assuring a long life. The MINI TWIST is user-friendly and astonishes for its simplicity. It makes possible a grow of productivity of the worker himself. The machine is feeded by a reel of plastic wire, so-called "Twist band" which has a metal wire inside.

Request for a quote

FERPLAST SNC

Italy

TABLE MONOBLOC SEALER WITH MANUALLY OPERATED SEALING BAR AN INCORPORATED ROLL HOLDER The SP 600 is equipped with sealing bar with NI-CR wire for simultaneous cutting and welding of the film. Allows to obtain a polyethylene or polypropylene bag, perfectly welded and trimmed, using the normal fold film. Suitable for use in laundries, shirt factories, the textile sector in general, but is also suitable for the food sector for the packaging of the bread. Operation: Place the coil with the open side facing the operator Insert the open-film blade between the two flaps Unroll the film to the desired length Lower the sealing bar and cut the bag Enter the product in the bag and make the welding of the side remained open.

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC SEALER SM 40 P - PLASTIC BAND Pneumatic sealer Mod. MINI SM 40 P, robust and safe, built entirely in painted steel suitable for closing polythene bags with clipband (plastic with double metal core). Also available with engraved date or ink date. All parts in contact are made of AISI 304 stainless steel suitable for contact with food.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Use: Designed for soldering or crimping on mineral insulated sheath cable or crimping on insulated wire. Construction: Brass machined, nickel plated insert with 0.1 mm tolerance on the cable OD.

Request for a quote

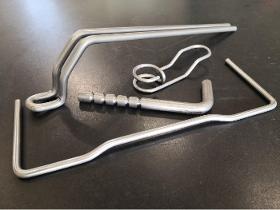

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Application: Crimp-insert can be fitted in the entrance hole of the connector. Designed for soldering or crimping on mineral insulated metal sheathed cable or crimping on insulated wire. Construction: • Brass machined insert with 0,1 mm tolerance on the cable O.D. The adapter fits in all standard connectors.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

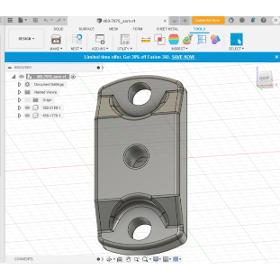

METAL-TECH

Poland

DESIGNING DETAILS FOR THE CUSTOMER'S NEEDS

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

At our sites in Rothenburg/Saale, Hamm, Brandenburg and Nedri Industriedraht (Hamm), we manufacture iron and fabrication wire for the machine, plant and steel construction industry, shopfitting, displays, automotive, furniture industry, household goods, chains, blasting material, tool carriers, filter industry, fence construction, garden and landscape design, connecting elements, logistics, construction industry, electrical and cable industry, bent wire parts, household appliances and gastronomy, animal husbandry, welding technology, lightning protection systems, gabions, packaging industry.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We are specialized manufacturers of wire products tailored to the requirements of our customers. We operate two modern CNC 3D wire bending centers with the following parameters: CNC bending wire center Numalliance 310 OPT Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 10 mm 3D CNC bending wire center Numalliance 214 TF Machine parameters: Max. wire tensile strength: up to 600 N/mm² or 85 Ksi Wire diameter: From 2.5 to 14 mm These machines enable us to create complex and precise shapes according to specifications, ensuring high quality and customer satisfaction.

Request for a quote

SCHNELL SPA

Italy

The rotor type wire straightening machine RI 12 is suitable for processing a wide range of smooth cold drawn industrial wires from Ø 4mm to Ø 12mm. The 4 independent servomotors allow Excellent straightening quality; Max. pulling speed 160 m/min; Burrfree highprecision cutting (tolerance of ±0.1 mm). A wide range of wires can be processed depending on the machine configuration from mild steel to annealed and galvanized wire, highstrength steels such as stainless steel, springs steel and nonferrous wires such as brass, bronze, copper and aluminum using special equipment. The wide range of accessories allows you to customize the machine to the different needs of the industrial market. Available versions RI 12/ML The manual setting of the mechanical lengthstop will enable processing wires with a bar length accuracy of ±0,1 mm. This newly designed contactless lengthstop enables to action the cut without the conventional

Request for a quote

SCHNELL SPA

Italy

The rotor type wire straightening machine RI 8 is suitable for processing a wide range of smooth cold drawn industrial wires from Ø 3mm to Ø 8mm. The 4 independent servomotors allow Excellent straightening quality; Max. pulling speed 160 m/min; Burrfree highprecision cutting (tolerance of ±0.1 mm). A wide range of wires can be processed depending on the machine configuration from mild steel to annealed and galvanized wire, highstrength steels such as stainless steel, springs steel and nonferrous wires such as brass, bronze, copper and aluminum using special equipment. The wide range of accessories allows you to customize the machine to the different needs of the industrial market. Available versions RI 8/ML The manual setting of the mechanical lengthstop will enable processing wires with a bar length accuracy of ±0,1 mm. This newly designed contactless lengthstop enables to action the cut without the conventional

Request for a quote

SCHNELL SPA

Italy

The rotor type wire straightening machine RI 6 is suitable for processing a wide range of smooth cold drawn industrial wires from Ø 2,5mm to Ø 6mm. The 4 independent servomotors allow Excellent straightening quality; Max. pulling speed 160 m/min; Burrfree highprecision cutting (tolerance of ±0.1 mm). A wide range of wires can be processed depending on the machine configuration from mild steel to annealed and galvanized wire, highstrength steels such as stainless steel, springs steel and nonferrous wires such as brass, bronze, copper and aluminum using special equipment. The wide range of accessories allows you to customize the machine to the different needs of the industrial market

Request for a quote

SCHNELL SPA

Italy

Electromechanical mesh cutting machine. It cuts in two directions thanks to the two kW 3 cutting motors, a kW 0.75 press motor and a kW 0.55 feeding motor. It is equipped with Reinforced framework; Continuous shear cutting unit; Rubber inlaid meshpressing beam.

Request for a quote

SCHNELL SPA

Italy

Rotor type wire straightening machine for the production of cuttosize wires up to Ø 6 mm (#3). Driven by digital electric servomotors. Max pulling speed 160 m/ min (525 ft/ min) High speed cutting unit with brushless (less than 0.1 sec) Web Teleassistance Available versions Fixed cut with adjustable backstop length for a maximum cutting precision (± 0.5 mm).

Request for a quote

SCHNELL SPA

Italy

Rotor type wire straightening machine for the production of cuttosize wires up to Ø 12 mm (#3). Driven by digital electric servomotors. Max pulling speed 160 m/ min (525 ft/ min) High speed cutting unit with brushless (less than 0.1 sec) Web Teleassistance Available versions Fixed cut with adjustable backstop length for a maximum cutting precision (± 0.5 mm). Rotating cut system with automatic measurement via encoder for higher productivity (± 0.5 mm/m).

Request for a quote

SCHNELL SPA

Italy

Rotor type wire straightening machine for the production of cuttosize wires up to Ø 8 mm (0.315 in.). Driven by digital electric servomotors. Max pulling speed 160 m/min (525 ft/min) High speed cutting unit with brushless (less than 0.1 sec) Web Teleassistance Available versions Fixed cut with adjustable backstop length for a maximum cutting precision (± 0.5 mm). Fixed cut with automatic backstop length for a maximum cutting flexibility (± 0.5 mm). Rotating cut system with automatic measurement via encoder for higher productivity (± 0.5 mm/m).

Request for a quote

SCHNELL SPA

Italy

Automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Capacity 2 Ø 16 mm (#5) Max pulling speed 200 m/min (660 ft/min) Straighteners (horizontalsverticals) with electronic adjustment and independent position for the 2 wires Motorized wire change unit (Optional) Prestraightening Feeding Unit (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 6inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Multirotor wire straightening machine using coils up to Ø 20mm for the production of straight bars. 4 wheel drive pulling unit driven by servomotors for high speed production; Maximum pulling speed 140 m/min; The straightening system uses rotors, each one dedicated to a single bar diameter which guarantees perfectly straight bars and wire diameter changes in just a few seconds; Servomotor driven cutting unit guarantees high speed and high cutting accuracy; Twin Version (Optional) with double cutter, double channel, double pulling unit it allows the processing of two bars simultaneously, doubling the productivity of the machine. Lista Bar wire straightening and cutting machine can be equipped with Bundle aligning device on the ground with vibrators (Optional); Indexing carriage for the automatic collection and sorting of the bars produced (Optional); Storage rack pneumatically operated (Optional).

Request for a quoteResults for

Wire machining - Import exportNumber of results

106 ProductsCountries

Company type

Category

- Industrial cutting machine tools (14)

- Wire drawing and wire rod working machines (11)

- Wires and cables, steel (8)

- Electric and electronic components - machines for manufacturing (7)

- Copper wires and cables (6)

- Cutting, plastics - machinery (6)

- Recycling - machines and installations (4)

- Milling - steels and metals (3)

- Shearing machine tools (3)

- 3D scanner (2)

- Connectors, electronic (2)

- Forming - steels and metals (2)

- Mechanical engineering - custom work (2)

- Metal industrial presses (2)

- Mining and quarrying - machinery and equipment (2)

- Package sealing machinery (2)

- SMALL METAL PARTS (2)

- Tying machines (2)

- Adjustment - machine tools (1)

- Aluminium alloys (1)