- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire machining

Results for

Wire machining - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

In addition to our extensive range of bright steel, we manufacture all standard machining steel wires in various designs at our sites in Schwerte, Iserlohn and Nedri Industriedraht (Hamm). according to DIN EN 10263 part 2-4 according to DIN EN 10267 Special analyses on request

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical information The AI 01 E is a stripping machine driven by an electric motor. Exact stripping of different insulated wires up to an outer diameter of 5 mm is possible. Adjustments are very easy to handle with an adjustmend knob. In addition a special funnel to infeed thin wires is also delivered. Special: An integrated battery allows up to 10,000 working cycles when fully charged and without external power supply.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

Use: Designed for soldering or crimping on mineral insulated sheath cable or crimping on insulated wire. Construction: Brass machined, nickel plated insert with 0.1 mm tolerance on the cable OD.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

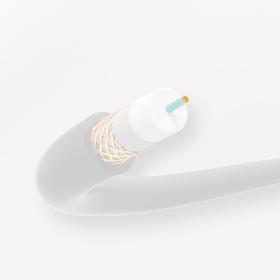

THERMA THERMOFÜHLER GMBH

Germany

Application: Crimp-insert can be fitted in the entrance hole of the connector. Designed for soldering or crimping on mineral insulated metal sheathed cable or crimping on insulated wire. Construction: • Brass machined insert with 0,1 mm tolerance on the cable O.D. The adapter fits in all standard connectors.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Special machines from Schmale Maschinenbau are equipped with an intelligent combination of technologies. The plant shown above is used to manufacture reinforcement items from solid material with a diameter of 20mm for the building industry. Servo-electric units such as bending slides, presses and finger benders are combined into customer-specific solutions for the production of individual items that can not be produced on standard machines. Schmale offers special machines for wire, tube and strip processing. You can watch various special machines for the production of different forming articles on our YouTube channel. https://www.youtube.com/channel/UCziuQiA3kXBVfH4ecLxQ2JA/videos

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

For Z+F ferrules and integration in fully automatic machines Technical information The electropneumatic driven, easily adaptable crimp modules CM-AEH are specifically designed for Z+F ferrules. They can be integrated in fully automatic machines. Wires and ferrules can be crimped in the range of 0.34 up to 4 mm2 (AWG 22 – 12). Atrapezoidal crimp (CM AEH-G) or quadro crimp (CM AEH-LS) corresponding to DIN46228 part 4 are available. The machines can universally be used in the specified range. An I/O interface enables easy integration and time optimized function in fully automatic machines. CM AEH-LS For loose insulated Z+F ferrules: 0.34 – 4 mm2 (AWG 22 – 12)/Crimping length 6 – 12 mm

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

At our sites in Rothenburg/Saale, Hamm, Brandenburg and Nedri Industriedraht (Hamm), we manufacture iron and fabrication wire for the machine, plant and steel construction industry, shopfitting, displays, automotive, furniture industry, household goods, chains, blasting material, tool carriers, filter industry, fence construction, garden and landscape design, connecting elements, logistics, construction industry, electrical and cable industry, bent wire parts, household appliances and gastronomy, animal husbandry, welding technology, lightning protection systems, gabions, packaging industry.

Request for a quote

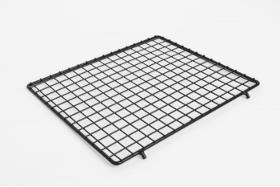

WDM DEUTENBERG GMBH

Germany

For certain modules extensive safety measures are required. Wire Meshes from WDM Deutenberg are ideally suitable for human and machine protection and guarantee an optimal working process.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

SCHOCK GROUP

Germany

Your project is in the best hands at SCHOCK. Our experienced engineers use state-of-the-art methods to plan all resources and guarantee on-time production. In addition, we supervise your tool over its entire life cycle. In mold and tool making, we work with high-quality milling machines, wire and die-sinking EDM machines, and modern CNC-controlled grinding machines.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Unslotted corrugated tubes are used to protect cable wires and cable harnesses. When cutting this corrugated tube sheathing to length, it is important to cut precisely and reliably on the crest of the wave, to avoid forming sharp cutting edges which damage the in-drawn cable wires. Metzner corrugated tube cutting machines of the CT 4000 series process corrugated tubes with great reliability and precision. Thanks to our many years of experience in processing corrugated tubes, we know the challenges that some corrugated tubes present and are well prepared for them. Our wide range of standard equipment ensures the best possible processing of your corrugated tubes. l The Metzner CT 4200 additionally offers an integrated slitting device for automatic slitting of unslit corrugated tubes. For material diameters from 7.5 mm to 40 mm.

Request for a quote

SCHOCK GROUP

Germany

Precision in toolmaking is crucial for the quality of your products. Our experienced mold-making team manufactures your tools professionally and functionally. Your project is in the best hands at SCHOCK. Our experienced engineers plan all resources with the most modern methods and guarantee on-time production. Furthermore, we provide full lifecycle support for your tools. In mold and toolmaking, we utilize high-quality milling machines, wire and sinker EDM machines, as well as modern CNC-controlled grinding machines. Our service offerings in the field of injection mold tooling include, among others: Injection molds Multi-component molds (rotary tables, index plates, core-back, transfer technology) Insert technology Gas internal pressure (GID) Foil overmolding (IMD) Thermoset molds Prototype and small-series molds Injection molds: up to 1,000 x 800 mm and 2.5 tons Multi-component molds: rotary tables, index plates, core-back, transfer technology

Request for a quote

EWM AG

Germany

Compact inverter welding machine with integrated wire feed mechanism. Available with 3 different control variants: LP, HP, Expert 2.0. Can be retrofitted with optional modular water block Cool 50 U40 or tool box for storing welding accessories, e.g. welding torch. — Excellent Multimatrix welding characteristics — Equipped at no extra charge with Synergic characteristics for GMAW welding of steel/CrNi/aluminium — Equipped at no extra charge with EWM Synergic characteristics for forceArc, forceArc puls, rootArc, rootArc puls and superPuls — Suitable for MMA welding, TIG welding and gouging at no extra charge — 16 individually configurable programs for each welding task (JOB) — Large power reserves thanks to high duty cycle with all components heating up less as a result, guaranteeing a longer service life for machines when in use — Adjustable start and end crater functions — Synergic or manual welding mode

Request for a quote

LEONI DRAHT GMBH

Germany

Round copper wire made from Cu-ETP1, Cu-OF1 and LEONI Histral® alloys, in bare, tin-plated, nickel-plated and silver-plated, soft annealed. Single wire diameter ranging from Ø 0.05 mm to Ø 0.254 mm. Number of wires used for strands: between 2 and 16 (subject to single-wire diameter). Single wire or multi wire on special bobbins fit for use in braiding machines. The braids manufactured by these machines are used in cables and conductors geared towards electromagnetic shielding or protection against damage as well as serving as a reinforcement.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

It doesn’t get any more flexible: The MICO-M generator comes with casters so that it can be moved quickly wherever needed. Customers may choose between a medium-frequency (20, 25, or 30 kW) and a high-frequency version (15 kW). All-round solution for induction heating This induction technology has a wide variety of applications: Brazing flat copper wires for machines, heating stress bolts in the construction of power plants, or hardening forming tools — are only a few of the examples. The secret of the machine’s success is its intelligent mix of compact size, quality, and mobility.A MICO-M energy container includes the generator itself, the active coolant system, the PLC system controller, and the hose bundle. The entire unit is also easy to move around with the casters.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Assembly of plant components and machines We assemble plant components and complete machines including electrical wiring, pneumatics and hydraulics in our factory buildings. Our 55 specialists in the assembly departments are waiting for your challenge. Key features own production of large diameter pipelines Performance of surface coatings Complete systems or components Series or individual assembly Electric, pneumatic and hydraulic function test on test bench Advantages all from one supplier installation-ready dispatch Handling of large components up to 400t total weight Factory commissioning personal contacts

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LEONI DRAHT GMBH

Germany

High-precision silver-plated single wire used as core for coaxial cables. Size range from Ø 0.10 mm to Ø 1.8 mm, manufactured on a specially designed machine. HF wire is characterised by a highly constant diameter, outstanding centricity and an extremely pure surface.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 060 Cutting and forming Device for jumper wires Description The Streckfuss model C060 is designed to cut and form 20 to 22 gauge jumper wires. The machine has an adjustable center to center distance and uses interchangeable die sets to vary the cut length. The wire straightener, feed clamp and backlash assembly combined with an adjustable feed stroke produce a precise jumper wire every time. Components

Request for a quoteResults for

Wire machining - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Wires and cables, steel (2)

- Copper wires and cables (2)

- 3D scanner (2)

- Connectors, electronic (2)

- Forming - steels and metals (2)

- Mechanical engineering - custom work (2)

- Cutting - steels and metals (1)

- Gratings, metal (1)

- Import-export - mechanical engineering (1)

- Induction heating systems (1)

- Injection moulding of rubber and plastic (1)

- Laser - cutting and welding machines (1)

- Welding, soldering and brazing - equipment and supplies (1)