- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wet painting

Results for

Wet painting - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

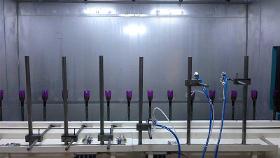

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Powder and Wet paint equipment must be determined and selected carefully according to the properties of the parts to be painted. In our systems, we use the highest quality, most efficient and most reliable, manual and automatic powder and wet paint guns, single and multi-axis robots.

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

Max. product dimensions W=4500mm L=8000mm H=3400mm. Sandblasting is also available for stainless steel, which is separated from other steel to prevent contamination. Upon customer request, we also employ laser removal of impurities on the surface. Customers can choose from different sandblasting roughnesses depending on project needs.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Lackieranlagen aus dem Hause Rippert sind vielseitige Alleskönner. Autoteile, Möbelstücke oder Kunststoffzubehör können damit präzise lackiert werden und Sie haben darüber hinaus die Möglichkeit manuelle Elemente wie Spritztische oder -wände sowie automatisierte Komponenten zu kombinieren. Natürlich können wir Lackierabläufe mit Hilfe modernster Robotik für Sie auch vollautomatisiert ablaufen lassen. Bei Rippert entwickeln und planen wir Lackieranlagen gemeinsam mit Ihnen, um alle Voraussetzungen für die optimale Oberflächenbehandlung Ihrer Produkte zu schaffen. Vom Werkstück für PKW über einzelne Bestandteile von Möbeln bis zur Oberflächenbehandlung von ganzen Kunststoffplatten zur späteren Weiterverarbeitung ist alles möglich. Unsere Anlagen stehen für modernste Technik und höchste Effizienz! Eine Lackieranlage muss heute vielen Anforderungen genügen. Sicherlich muss diese Komponente im Anlagenbau in erster Linie dafür sorgen, dass Lacke gleichmäßig auf die Werkstücke aufgetragen werden. In Zeiten des steigenden Kostendrucks müssen Lackieranlagen darüber hinaus immer kostensparender arbeiten. Wir planen und montieren deshalb Anlagen, die höchst effizient mit einem Maximum an Leistung für ein Minimum an Kosten für Sie arbeiten, ohne dass dabei Qualitätseinbußen entstehen. Darüber hinaus ist der Umweltschutz ein wichtiger Faktor. Durch aufwändige Filtertechniken und Abscheidefunktionen erfüllen unsere Anlagen selbst strengste Umweltschutzauflagen.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Partial or complete evaporation of the volatile portions of paints before the film formation is completed and/or before a further coating can be applied. In wet painting, the majority of the solvents are already released and exhausted during the coating procedure. In order to dry the freshly applied paint layer, it is necessary to also remove and exhaust the remaining solvents as far as possible. This takes place in special flash-off zones by means of exhaust air and conditioned supply air or fresh air. Flash-off zones are usually the link between paint application and drying. A certain degree of preliminary drying often also takes place here by working with a slightly raised room temperature. Some processes also require a gentle transition to higher temperatures in the dryer. All this can be realised in flash-off zones. On top of that, flash-off zones offer particular protection of the freshly painted surfaces against outside influences, especially dust.

Request for a quote

METAL IN LTD

Bulgaria

The company possess with two lines for powder coating, in which can be manufacture products with maximum dimensions 1000x2000x600 mm. We also make a wet painting.

Request for a quote

METAL IN LTD

Bulgaria

We offer MIG-MAG and WIG welding with maximum power of electricity 400 A. Our welding machines are KEMPPI and MILLER. We make welding of steel details, tube constructions with length till 6 meters and weight till 3 tones. We also offer spot welding and robotic welding (Fanuc) at details with length till 3 meters and width till 1.5 meters, by one or by two sides. We weld ferrous metals, stainless steel and aluminum. After welding we make cleaning of welding and painting (powder and wet).

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The main part of the wet painting lines that we have produced is wet painting booths. Wet painting booths are used to apply wet paint on the material under the most ideal conditions after the surface cleaning process and to prevent the paint that can not hold onto the work piece from being escaped to the environment. The wet paint is atomized by high pressure air and applied on the part that is going to be painted. It is preferred because it is easy to apply and gives good results. As Rota Makine, we design lines with conveyor and robots to offer our esteemed customers who want to make production with high capacity, automation and untouched. Our wet painting booths are categorized as With Water Curtain and With Solid Filter because of their different advantages. Wet enameling cabinets for enamel applications are also available in our scope of production.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with solid filter, the air is sucked through the filters by exhaust fans while the unused wet paint is held by paper or fiber filters. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our Infrared ovens can be produced as conveyor belt tunnel or internal return (U) type. Our ovens have andirect heating system with radiation heat transfer. They are used due to the cure flat shaped parts after wet or powder coating paint applications. They are preferred because they can cure the paint three times faster than the convectional type ovens. They can be produced with natural gas or lamp type infrareds. The inner surfaces of our ovens’ panels are produced with a galvanizedor stainless steel sheets and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thicknesses determined and rock wool or glass wool is used for insulation.

Request for a quote

PERGEL METAL

Turkey

The paint plant is especially preferred in the construction and furniture industry. The materials used in this sector are painted both for aesthetic purposes and for protection purposes. Paint plants is a far-reaching term. There are varieties. Its quality and form vary. In general, the age paint plant is more preferable. There is a wet paint booth, conveyor system and drying oven in the paint plant. It is produced in accordance with the most suitable conditions and made suitable for use.

Request for a quote

TECHNICIS

France

Filters made at our factory in Nantes (France) Standard Filtr’Overspray is well adapted to filtration of paint overspray in spray booths. It is easy to manipulate and to stock. Its lifetime, 6 times longer than other filtering medias on the market, allows to make important costs reductions. This filter is perfectly adapted to filtration of any wet overspray particles (paints, varnishes, gel coat, glue, silicone, polyester etc…) Advantages of this filter : - Lifetime up to 6 times longer than other filtering medias on the market - Easy installation and manipulation - Environment friendly materials according to ISO 14000 - Adapted to filtration of solvent paints and water based paints This filter can be used in all spray booth with horizontal and vertical airflow.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Part size 400*400*500mm laser cutting, flame cutting the sheets and then welding,finally wet painting

Request for a quote

4CR INTERNATIONAL GMBH

Germany

Stone chip protection that allows wet-on-wet painting on spoilers, doors, etc. Fast drying, durable and elastic. Overpaintable.

4CR INTERNATIONAL GMBH

Germany

Stone chip protection that allows wet-on-wet painting on spoilers, doors, etc. Fast drying, durable and elastic. Overpaintable.

4CR INTERNATIONAL GMBH

Germany

Stone chip protection that allows wet-on-wet painting on spoilers, doors, etc. Fast drying, durable and elastic. Overpaintable.

Do you sell or make similar products?

Sign up to europages and have your products listed

4CR INTERNATIONAL GMBH

Germany

Stone chip protection that allows wet-on-wet painting on spoilers, doors, etc. Fast drying, durable and elastic. Overpaintable.

4CR INTERNATIONAL GMBH

Germany

Non-woven material for matting vehicle surfaces before painting. Use wet or dry.

4CR INTERNATIONAL GMBH

Germany

Non-woven material for matting vehicle surfaces before painting. Use wet or dry.

4CR INTERNATIONAL GMBH

Germany

Non-woven material for matting vehicle surfaces before painting. Use wet or dry.

HODA, UAB

Lithuania

HODA, UAB can wet paint the plastic parts to give you and your final customer the best look of your product.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB produces plastic products for the electrical industry. Our company provides that services: mould tool manufacturing, plastic injection moulding, insert overmoulding, DC (dual- component) injection moulding, gas assisted injection moulding, thermoset moulding, plastic blow moulding, decoration, tampo printing, screen printing, wet painting, assembly and packaging, local and international delivery.

Request for a quote

HODA, UAB

Lithuania

At the moment HODA, UAB operates 54 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts from a fraction of gram up to six kilograms of mass. HODA, UAB services: Mould tool manufacturing, Plastic injection moulding, Insert overmoulding, DC (dual- component) injection moulding, Gas assisted injection moulding, Thermoset moulding, Plastic blow moulding, Decoration, Tampo printing, Screen printing, Wet painting, Assembly and packaging, Local and international delivery.

Request for a quote

ONE2ID B.V.

Netherlands

Industrial processes place high demands on the type of labels used for identification. These include processes such as painting, powder coating, wet painting, soldering, chemical pre-treatment, KTL painting processes, autoclave processes (sterilisation) and printed circuit board (PCB) production. During these processes, barcode labels are often exposed to extremely high temperatures or aggressive industrial cleaning agents, which a simple paper label cannot withstand. ONE2ID has a wide range of heat-resistant materials that can be used up to very high temperatures.

Request for a quote

ONE2ID B.V.

Netherlands

Labelling parts and products that undergo industrial processes, such as chemical pre-treatment or cleaning, powder coating, anodising and wet painting, is challenging, but not impossible. This requires a special type of label that not only has a strong adhesive, but also protects the information on the label. Our specialists have designed a label that can be applied prior to coating or chemical cleaning processes and remains securely in place during the treatment: the Paintmask label. A laminate attached to the Paintmask label protects the product information on the label. After the paint has cured or the cleaning or pre-treatment has been completed, you can simply remove the laminate and reveal the information on the label unaffected and ready to be scanned.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Strong crimped plug/cable attachment Circular cable cross section to reduce kinking and twisting Various cable lengths available Types: MicroMag surface + air thermocouples Easy to place, ideal for difficult-to-access car body shell areas Encapsulated magnet design allows reliable direct use even on wet painted and e-coated substrates IRMAG surface thermocouple Designed to measure ferrous substrates in IR cure ovens Robust alternative to Adhesive Patch thermocouple, combines easy attachment and fast thermocouple response Magnetic surface + air thermocouples Magnet offset from sensor prevents heatsink effect PTFE handle for easy removal or repositioning PTFE-coated to prevent sticking Aluclamp surface thermocouple Clips onto the edge of an aluminum car hood or other nonferrous panel Allows measurement of surface temperature at center of panel Aluminum automotive thermocouples with a spring-loaded bobbin for use on aluminum car body shells

Request for a quote

TECHNOGROUP

Bulgaria

As a company with long-term experience in metal painting, we suggest wet painting and powder coating. The choice of paints is made according to the clients’ preferences. The paints and the finish are chosen by the client. The client can choose between glossy, semi matte or matte color.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quoteResults for

Wet painting - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Paints, synthetic resin (8)

- Paint spray guns and accessories (5)

- Anti-corrosion coatings (2)

- Galvanization - steels and metals (2)

- Paints and varnishes (2)

- Additives, dyes and pigments - industrial (1)

- Bar codes - printing machines (1)

- Coating machinery (1)

- Coatings, insulating (1)

- Filtering equipment and supplies (1)

- Filters, liquid (1)

- Heat treatment of steels and metals (1)

- Industrial paintings (1)

- Labels, office use (1)

- Motor mechanics - hand tools, non power (1)

- Perforation of steels and metals (1)

- Sand blasting - steels and metals (1)

- Steels and metals - welding and brazing (1)

- Temperature sensing devices (1)

- Welding work - steels and metal (1)