- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding electrodes

Results for

Welding electrodes - Import export

KJELLBERG VERTRIEB GMBH

Germany

Surfacing electrodes for diverse demands acc. to hardness, toughness, type of stress, machina

Request for a quote

WELDING ELECTRODES FACTORY ELECTRODE GROUP LLC

Ukraine

Electrodes E6013 RC - rutile cellulosic Electrodes E6013 R - rutile Electrodes E7018 - basic Stainless electrodes and other special electrodes

Request for a quote

PLANSEE SE

Austria

Welding electrodes made of tungsten, molybdenum and their alloys are particularly suitable for welding highly conductive materials such as copper. They are used in the following processes: Spot welding, Roller welding, Projection welding, Upset welding. Welding electrodes made from our refractory metals and their alloys have a relatively high level of electrical conductivity while also exhibiting outstanding stability at high temperatures. They therefore have a considerably longer service life than conventional materials such as copper and copper alloys.

Request for a quote

DR. PAUL LOHMANN GMBH & CO. KGAA

Germany

Dr. Paul Lohmann® offers Dipotassium Oxalate 1-hydrate as fine powder and as crystals in chem. pure. In the oral care sector, it is used for pain desensitization. For industrial applications, it is used as a potassium source for plasma welding electrodes, complexing and precipitating agents for metals and for the preparation and modification of catalyst surfaces. CAS 6487-48-5 EINECS 209-506-8 Dr. Paul Lohmann® carries out product and application development in close cooperation with customers. This includes the adaptation of chemical and physical parameters such as bulk density, wettability, particle size, purity or pH-value.

Request for a quote

EWG E. WAGENER GMBH

Germany

Tungsten is a silver-white, metallically shiny or grey heavy metal (depending on whether it occurs in pieces or in powder form). Hard and brittle, tungsten can, however, be made ductile by hammering and drawn into thin wires, for example. Tungsten belongs to the group of refractory metals, which are characterized by high melting points, good thermal conductivity and low thermal expansion, among other things. High corrosion resistance is a further characteristic. Tungsten is suitable for the construction of resistance heating elements, the manufacture of filaments (especially in high-temperature furnace construction and electrical engineering), engine parts, X-ray anodes and welding electrodes. Pins made of tungsten can be fused into high melting point glass for the passage of current. Tungsten is also used in nuclear technology. Tungsten alloys are used about 80% in the steel industry and about 10% each in the hard metal and electrical industries.

Request for a quote

CMPLAST

Poland

Our company's offer includes welding of steel structures made of stainless steel and carbon steel. Welding is carried out using the method MIG / MAG creation of an electric arc between the head and the material. It is covered with shields of mechanical gases such as, for example, neutral (argon) or chemically active (carbon dioxide); TIG welding using a tungsten electrode and a shield of noble (inert) gas, most often argon. We combine elements of standard size as well as largesize items We provide welds with the highest usable parameters, but after the welding process, the combined elements are additionally grinded and we remove any sharp edges or endings

Request for a quote

ANKARA BRONZ

Turkey

ECU 99,9 % : Electrolytic is used as copper material with a conductivity of 58, electrode in erosion, high-low current panel and busbar in substations. Among our standard products: Rod, Sheet Plate, Straight pipe, Tube Coil, Box profile, Grounding rod - plate, Roofing, Copper fittings and thin wires. Also, sheet plate measurements which do not have a standard are brought to necessary measurement by forging at desired dimensions. Parts that require CU-Cr-Zr (Chromium alloy) High electricity conductivity, hardness and strength at high temperatures: Are used as point welding electrode and seam welding disc at the source of low carbon steels (Panel radiator, Gasoline warehouse, etc.) and Galvanized steel plate (Automotive and white goods), electrode holder at spot welding machines, plunger electrode at erosion machines and contact busbar at substations.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Tungsten inert gas (TIG) welding offers many advantages over other fusion welding methods, such as the complete absence of spatter and low welding-fume emissions. Since TIG welding uses a non-consumable electrode, the process is ideal for welding so-called root passes or in forced positions due to the decoupling of current and welding consumables.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 37Ω±15% Dimension: L80*φ5.0mm Electrode: Welding 2 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 310Ω±10% Dimension: L60*φ3.8mm Electrode: Welding 2 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Usage: Mainly applied to model 933 electronic soldering iron Voltage: 220VAC Heating Resistance: 140Ω±10% Dimension: L60*φ3.8mm Electrode: Welding 4 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification: Application: Used for 936 soldering station Voltage: 24VAC Heating Resistance: 3.0±0.3Ω (23℃±2℃) Dimension: L60*φ3.8mm Electrode: Welding 4 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Black Coating Type 220V 230V 240V Alumina Pellet Ceramic Igniter Alumina Ceramic Hor Surface Igniter can reach a permanent working temperature above 1000℃;Since air can through and around inside and outside of the heater tube. Heat can be transferred from both inside and outside of ther heater element. Igniting wood chips, firewood, coal bricks or other biomass fuel. > Dimension: 106*11.5mm (Or Customized) > Voltage: 230V > Power: 270W - 315W > Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) > Range of temperature: 800~1000°C > Electrode: Welding leads on the electrode FEATURES: 1、Black coating type 2、300W+5%-10% 3、60-90 seconds ignition time 4、Available in 120V 220V-240V 5、ROHS/REACH certification 6、Many design available 7、Customized welcome

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

The Invertec® 165S and SX welders offer much more than you would expect from a welder of this size. They have all the power of a heavy-duty professional welder that you can take to the most demanding job sites. Low energy consumption and high duty cycle: they are ideal for maintenance and for all professional, industrial or construction site applications. Exceptional performance: high duty cycle at 40°C. Easy to use: Hot Start function to improve arc strike and Arc Force function to prevent electrode sticking. Versatile: welding with any coated electrode (except cellulosic) Compatible with motor-generator. Light: less than 9 kg Practical: thanks to the practical carrying strap.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOSSE SP. Z O.O.

Poland

Our company meets the quality requirements of PN-EN 1090-1 standard for welding metal materials and has a quality management certificate in ISO 3834-2 welding Our welders are authorized to weld using methods such as: MAG 135 - welding metal electrode in active gas shield MAG 136 - arc welding in the active gas shield powder wire MAG 138 - welding with consumable electrode in the shield of active gas powder wire with metal core SAW 121 - submerged arc welding

Request for a quote

VOSSE SP. Z O.O.

Poland

Metal welding is, the process of welding metals together, performed using heat, superheating or using a welding agent. Each of the above-mentioned solutions is distinguished by different properties, allowing to combine different types of materials and also to apply welding in a specific, well-defined area. We offer our customers comprehensive services in this area with the highest international standards. At our facility, we weld using MAG and TIG methods, in accordance with the international standards set forth in EN ISO 3834-2 for welding metal materials and EN ISO 1090-2. We weld both black and stainless steel. We manufacture structures up to EXC3 class. We have more than 70 WPQR welding qualifications according to EN ISO 15614. Our welders are qualified to weld by methods: MAG 135 - Arc welding with solid wire in active gas shielding. MAG 136 - Arc welding with powdered wire in active gas shielding. TIG 141 - Welding with non-fusible tungsten electrode in an inert gas shield.

Request for a quote

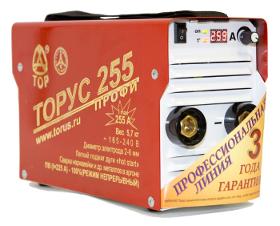

COMPANY TOR

Russia

Operating from a single-phase 220 V network, the industrial welding inverter ТОРУС-250 Extra has an increased arc welding current up to 250 Amperes and, therefore, an increased percentage of operating time (TP). This allows performing continuous welding works: the device provides TP = 100% at an arc welding current of up to 225 Amperes (electrodes with a diameter of 5 – 6 mm). The power consumption when welding with “household” electrodes with a diameter of 3 mm is such that the device can be connected to a regular household outlet. Thus, the ТОРУС-250 Extra device is universal for industrial facilities and for cottage areas.

Request for a quote

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

COMPANY TOR

Russia

The inverter machine VIKING 500A PRO is used for manual arc welding of metal blanks. The inverter has a functional control panel with a digital display that displays the main operating parameters. The device is equipped with overload protection and voltage surge protection. The technologies applied during the manufacture of VIKING 500A PRO devices allow performing any tasks in welding, surfacing and cutting metal structures for performing work with any kind of electrodes with a diameter of up to 6 mm and a maximum arc welding current of up to 500А (100% at 420 A). The welding inverter machine can be used at low temperatures and reduced supply voltage. Adjustable functions of hot start and arc reheat imply the ability to adjust the operation of the device with minimal spattering and allow you to perform work in any spatial position of the electrode and welded surfaces.

Request for a quote

EWM AG

Germany

TIG welding torches, gas- or water-cooled from 150 A (gas-cooled) up to 400 A (water-cooled). — TIG welding torch with a highly flexible hose package — Ergonomic GRIP handle for a secure hold and ergonomic use — Excellent HF reliability — Ready to weld with tungsten electrode, gas nozzle and back cap

Request for a quote

EWM AG

Germany

— Inverter welding machine, DC — Very light-weight, only 4,7 kg – housing made of aluminium and impact-resistant plastic — Portable, shoulder strap — MMA and TIG lift arc welding — Cellulose electrodes: 100% safe for vertical-down welding — Welding of stick electrodes up to 4 mm — Pulsed MMA welding: — Especially suitable for root welding — Outstanding gap bridging with no sagging of the root side — Fine-flaked weld surface with a TIG look for final passes — Less finishing work thanks to less spatter — Ideal for difficult electrodes — Less distortion thanks to controlled heat input — Pulsed TIG welding with up to 2 kHz — Connection capability for remote control — IP23 spray water protected — Arcforce, hot start, antistick — Energy efficient due to standby mode — 3.5 m mains lead with 16 A earthed plug — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quoteResults for

Welding electrodes - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Welding work - steels and metal (8)

- Ceramics (5)

- Stainless steels (4)

- Welding, soldering and brazing - equipment and supplies (4)

- Autogenous welding machines (3)

- Harvesting machinery and equipment (3)

- Machine tools, cutting - parts and accessories (2)

- Welding, electric - equipment and supplies (2)

- Steels and metals - welding and brazing (1)

- Cast iron items (1)

- Chemistry, inorganic - raw materials and derivatives (1)

- Copper and copper alloys (1)

- Electronic optic components (1)

- Foundries - copper, bronze and brass (1)

- Iron alloys (1)

- Laser - cutting and welding machines (1)

- Steel, tool (1)

- Steels, nickel (1)

- Vacuum cleaners - industrial (1)

- Wire drawing - ferrous metal (1)