- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tungsten carbide die

Results for

Tungsten carbide die - Import export

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

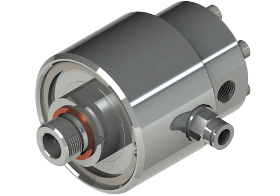

single inlet/outlet line rotor + housing, material stainless steel tungsten carbide/tungsten carbide seal 160,0 bar hydraulic oil water TEMPERATURE MAXIMUM 90 °C hydraulic oil water SPEED MAXIMUM 1500 1/min DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2")

Request for a quote

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

METALLSTANDART LTD

Russia

It is used in mechanical processing of metals and non-metallic structural materials in mechanical engineering (turning, milling, planing, chiseling and drilling). Hard alloys and composite materials based on tungsten carbide are widely used In the mining industry, as well as mixtures of tungsten carbide, titanium carbide, tantalum carbide (TT grade for particularly severe processing conditions, e.g. chiselling and planing of forgings made of heat-resistant steels, or impact drilling of heavy-duty materials). We buy scrap of the following categories: Tungsten 4, Tungsten 5, Tungsten 6

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

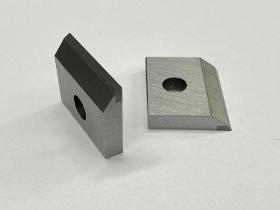

Different tungsten carbide qualities with a hardness above those of the standard and PM special qualities. Through clean grinding materials, we achieve a long working life through high resistance to wear.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin: China Product name: WC-12Co Application: thermal spraying, HVOF, etc., HVOF, D-Gun Shape: powder, ball like Material:tungsten carbide, cobalt Chemical Composition: WC, Co, etc., Co:12.0;C:5.4;W Bal Dimensions: -325mesh/+15 um;-45 um/+15 um Flow density: 20 sec 4.4g/cm3 Color: gray Supply Ability: 80000 Kilogram/Kilograms per Year Lead time:15days Port of shipment: Xiamen Applicable process: 1.for plasma spraying (PTA) 2.for supersonic spraying (HVOF/HVAF).

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

tungsten carbide compound powder

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Silicon carbide is a kind of inorganic non-metallic materials, with excellent mechanical strength and hardness, small creep deformation, good oxidation resistance, good corrosion resistance and good wear resistance, it is an ideal choice for high temperature engineering materials. Due to the outstanding properties, silicon carbide ceramic is also recognized as a mechanical sealing ring material better than metals, tungsten carbide, al2o3 ceramics and more. Place of Origin: China Material: Silicon Carbide (SiC) Color: Black/grey Material: Silicon Carbide Ceramics Volume density: 3.10-3.15 g/cm3 Max temperature: 1600°C Silicon carbide content: ≥98% Flexural Strength: ≥400 MPa Hardness: ≥ 92 HRA Size: Customizable Application: Industrial Furnaces Supply Ability: 5000000 Piece/Pieces per Month Packaging Details: Standard exporting packing Port of shipment: Xiamen Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

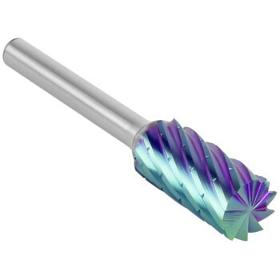

Tyrolit’s tungsten carbide burrs can machine materials like steel, stainless steel, non-ferrous metals, cast iron, and HSS. They come in various shapes and profiles, including tapered, cylindrical, ball-shaped, and special designs for angles, corners, and flutes. The parts are soldered with a copper alloy for impact resistance, enhancing safety and performance. Our burrs ensure first-class grinding with maximum economy, featuring long tool life due to a specially developed cutting edge geometry. The aggressive cutter profile allows for significant material removal in a short time, with reduced heat generation to protect both tool and workpiece, crucial for stainless steel to prevent discoloration. The new HPC-coated tungsten carbide burrs for cast iron, steel, and stainless steel offer higher performance, longer life, and better results. The advanced coating improves chip transport and doubles stock removal, with a distinctive Tyrolit color combination.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Metal-bonded grinding tools for flute grinding With the STARTEC XP-P+ product line, TYROLIT defines a new performance level for the flute grinding of tungsten carbide cutting tools. Two different diamond qualities and the innovative bond structure lead either to significantly reduced grinding forces or to a major increase in profile retention. The precision of the machined tools remains at the usual high level. Increased feed speed Easy profiling Extended dressing intervals

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our stationary cutting tools offer high quality and a broad range, including lab cut-off wheels, resin-bonded wheels for steel and stainless steel, diamond wheels for cast materials, and high-performance CBN and diamond wheels for tungsten carbides and HSS. Years of innovation have advanced stationary cutting. Tyrolit cut-off wheels are durable and easy to use due to collaboration with manufacturers and customers. We guarantee sustainable solutions, offering cut-off wheels for various applications and custom products. For machining steel, stainless steel, nonferrous metals, and stone, our resin-bonded cut-off wheels are ideal, providing low lateral friction and preventing discoloration. Premium lab cut-off wheels ensure fast, deformation-free sample cutting. Diamond saw blades for cast iron are preferred for their longer lifespan, reduced dust, and increased safety.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our files, bench stones, knife blade files and hollow chisel stones are available in different grit sizes from coarse to super fine depending on the desired application. Due to the large selection of different tools, the portfolio covers a wide variety of applications. The various files and stones can be used for machining tools in the woodworking and machine industries as well as for whetting knife blades. Tyrolit combination stones consist of two different grit sizes, allowing a wide variety of workpieces to be deburred. For improved ergonomics, certain products are equipped with handles to increase working comfort and make hard-to-reach places effortless to machine. One tool that no workshop should miss is the TYFIX hand rubbing brick, which allows you to effortlessly remove dirt, rust and paint from various surfaces. Tyrolit's tools are designed for different materials - from vitrified-bonded tools to resin- and electroplated diamond files for HSS and tungsten carbide.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

External cylindrical grinding is essential for achieving optimum surface finishes on workpieces like camshafts, crankshafts, and transmission shafts. It's used on various materials, including unalloyed, low-alloyed, and high-alloyed steels, HSS, tungsten carbide, industrial ceramics, and cast metals. The key to selecting the right tool lies in matching the grinding wheel to the specific requirements of the grinding application. This involves considering workpiece properties, tool, machine, settings, cooling lubricant, and dressing technology. Our high-quality tools and consulting services ensure optimal process parameters. Tyrolit offers a wide range of high-quality grinding tools for various applications and materials. We provide vitrified-bonded conventional wheels with different grains for specific materials, and resin-bonded high-performance tools made of CBN or diamond with our special bond system. The VIB STAR system reduces vibration for a smooth grinding process.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a comprehensive portfolio of bench grinding wheels for grinding various steels as well as tungsten carbide, cast iron and nonferrous metals. The assortment is additionally complemented by a selection of whetting and polishing wheels to guarantee permanently sharp tool edges. Vitrified-bonded bench grinding wheels are mainly used in workshops and repair stores. They can be universally used for grinding and sharpening various components. The coordinated specifications allow a wide range of applications from coarse to fine grinding. Whetting and polishing wheels from Tyrolit Tyrolit whetting and polishing wheels are particularly elastic and easy to true. Due to their structure, they generate the finest surfaces in the shortest possible time. At the recommended speed, they offer long tool lives and impressively cool grinding to maintain the cutting ability of your tools.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

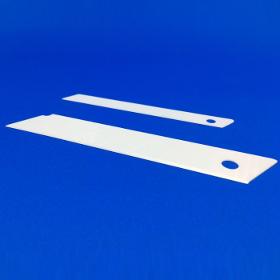

Ceramic Octagon Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

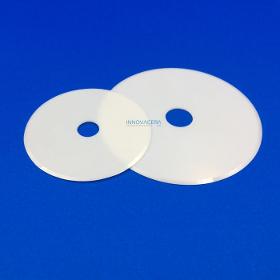

Ceramic Rotary Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Slotted Ceramic Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Si3N4 Silicon Nitride Tube Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Trapezoid Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ceramic blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents Precision manufacturing: Cylindricity up to 0.004mm, linear tolerance up to 0.001mm, dimensional accuracy up to 0.001mm, thread minimum machinable internal thread M2, thickness up to 0.02mm, concentricity up to 0.003mm, minimum aperture up to 0.07mm...And other parameters.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quoteResults for

Tungsten carbide die - Import exportNumber of results

62 ProductsCountries

Company type

Category

- Ceramics, industrial (15)

- Conveyor belts (4)

- Grinding - machine tools (4)

- Ceramics (3)

- Milling - machine tools (2)

- Adjustment - machine tools (1)

- Bearings, roller (1)

- Cutting - steels and metals (1)

- Drilling - machine tools (1)

- Electric motors and parts (1)

- Electricity - production and distribution (1)

- Machine tools - metal machining (1)

- Metal engraving - machine tools (1)

- Metal powders (1)

- Milling - steels and metals (1)

- Nozzles - ferrous metal (1)

- Scrap iron - salvaging and recycling (1)

- Silicones (1)

- Steel, tool (1)

- Steels and metals - forming and cutting (1)