- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tungsten carbide die

Results for

Tungsten carbide die - Import export

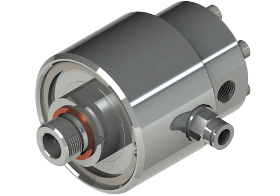

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

single inlet/outlet line rotor + housing, material stainless steel tungsten carbide/tungsten carbide seal 160,0 bar hydraulic oil water TEMPERATURE MAXIMUM 90 °C hydraulic oil water SPEED MAXIMUM 1500 1/min DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2")

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

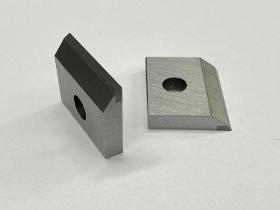

Different tungsten carbide qualities with a hardness above those of the standard and PM special qualities. Through clean grinding materials, we achieve a long working life through high resistance to wear.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

Most modern methods are applied in the production of our high quality Dial Test Indicators. They are both sensitive and shock-resistant. Here are some of the advantages applicable to the whole series: All features of the models reading up to 1 mm measuring range conform to DIN 2270. This applies to all deviation spans, the measuring force and the hysteresis error of the measuring force Automatic change of the direction of measurement Indication clockwise in all types Precise components, running in ruby bearings, warrant highest precision throughout Precision bearing for the lever shaft Body with 3 dovetail slides for clamping the stem and other equipment Body hard-chromed in order to protect the dovetail slides against damage Tungsten carbide ball 2 mm Ø in measuring inserts Dial adjustable by knurled bezel Supplied in a convenient box with transparent lid with 1 stem Ø 8 mm h 6 and 1 spanner for changing the contact points

Request for a quote

LEICA MICROSYSTEMS

Germany

The Leica EM RAPID milling system for pharmaceutical research enables sample preparation for analysis of active ingredient distribution on solid-dose pharmaceuticals. The instrument, using a tungsten carbide or diamond miller, decapsulates pills without smearing and features adjustable cutting speeds between 300 and 20,000 rpm, defined step-layer removal, low-noise extraction and filtration with a Hepa filter and single or multiple holders.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results. APPLICATIONS: Orthopedic implants (medical engineering) Turbine blades (for airplanes as well stationary turbines) Precision components, for example, for pumps and compressors Work pieces made from tungsten carbide and other hard metals Fan wheels for turbo chargers (automotive industry) Sintered components, etc.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE AIRLESS-spray valve S 830 Spray valve without atomizing air. Connections of valve on under-side. Control of S 830 via external pneumatic valves. Max. material pressure: 250 bar All standard airless nozzles can be fitted to the S 830. needle seat and needle : tungsten carbide

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE extrusion valve MMDV/MV (LV/KV) Small design. Suitable for application of glues, adhesives and oils. Available with long nozzle (LV) and short nozzle (KV). nozzle: stainless steel needle: tungsten carbide available nozzle dimensions: 0,2; 0,3; 0,4; 0,5; 0,6; 0,8; 1,0; 1,2; 1,5; 2,0; 2,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE extrusion valve MMKD 30 Very fast and exact valve for continuous or intermittend application of glues, adhesives and oils. Available with long nozzle (LV) and short nozzle (KV) nozzle: stainless steel needle: tungsten carbide available nozzle dimensions: 0,2; 0,3; 0,4; 0,5; 0,6; 0,8; 1,0; 1,2; 1,5; 2,0; 2,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE extrusion valve MMDD LV Small design. Suitable for application of glues, adhesives and oils. Available with long nozzle (LV) and short nozzle (KV) nozzle : stainless steel needle : tungsten carbide available nozzle dimensions : 0,2; 0,3; 0,4; 0,5; 0,6; 0,8; 1,0; 1,2; 1,5; 2,0; 2,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE extrusion valve MMDV and MMDV LV/KV Small design. Suitable for application of glues, adhesives and oils. Available with long nozzle (LV) and short nozzle (KV) nozzle: stainless steel needle: tungsten carbide available nozzle dimensions: 0,2; 0,3; 0,4; 0,5; 0,6; 0,8; 1,0; 1,2; 1,5; 2,0; 2,5 mm ø

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE Extrusionsventil MMKD 50 Very fast and exact valve for continuous or intermittend application of glues, adhesives and oils. Available with long nozzle (LV) and short nozzle (KV). The extreme short control air distances and the high speed solenoid gives this valve very fast and exact needle intermission cycles up to 200 cycles per second. nozzle: stainless steel needle: tungsten carbide available nozzle dimensions: 0,2; 0,3; 0,4; 0,5; 0,6; 0,8; 1,0; 1,2; 1,5; 2,0; 2,5 mm ø

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tungsten carbide die - Import exportNumber of results

17 ProductsCountries

Company type