- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermally conductive ceramics

Results for

Thermally conductive ceramics - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel. Features: > high fracture toughness > thermal expansion similar to cast iron > extremely high bending strength and tensile strength > high resistance to wear and to corrosion > low thermal conductivity Ceramic material composition: . TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

With its properties of electrical insulation and excellent thermal conductivity, Aluminum Nitride Ceramics is ideal for applications where heat dissipation is required. In addition, since it offers a coefficient of thermal expansion (CTE) near that of silicon, and excellent plasma resistance, it is used for semiconductor processing equipment components.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of aluminum nitride ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Ceramic Cavity Laser Reflectors Introductions : High purity porous alumina ceramic of 99% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity. Ceramic Reflector Prime Features: > Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk refectivity > 97% reflectance efficiency at 600-1000nm > Reflectance efficiency exceeds 95% across the wavelength range 400-1200nm (see curve) > Controlled porosity > Good thermal conductivity > High electrical resistivity Ceramic Cavity Laser Reflectors Physical properties: > Color: White > Bulk density (fired), Mg/m3 :3.1 > Porosity (apparent), % nominal :22 > Flexural strength (ASTM C1161, 3-point), MPa :170 > Thermal expansion coefficient 200-500C, 10-6 /C 7.9 200-1000C, 10-6 /C 9.0

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

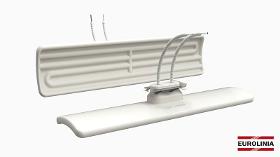

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

They are especially designed for quick adaptation in molds or surfaces where the use of rivets either causes problems or impossibility to use. Cuadrawatt cartridges are the better choice. Cartridges with a low density of watts are most recommended for moderate heating up to a maximum temperatures of 300ºC. The square tube is made of prime quality stainless steel. All the tubes are perfectly calibrated both inside and outside, into which a long-life ceramic piece is inserted. The tube resists a continuous temperature variation and has the best possible thermal conductivity, as the ceramic piece is in contact with the wall of the tube, which makes the most perfect heat distribution possible. Special Cold Sections: Distributed Wattage Single Circuit Element Independent Heat Zones Three Phase Element Dual Voltage Designs Thermocouple A,B,C RTD Elements Thermostats

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Heat Insulation and Low Thermal Conductivity; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

ADVANCED MAGNETIC TECHNOLOGIES AND CONSULTING (AMT&C)

Russia

The thermal conductivity measuring insert is intended for measurement of the thermal conductivity coefficient temperature dependencies in constant magnetic field using stationary method. The inner sample holder is equipped with the resistive heaters, resistive temperature sensors and Hall sensor. The thermal conductivity measuring insert characteristics: - relative measurement accuracy of thermal conductivity coefficient: 3 %; - sample dimensions: a rectangular plate 22×4×2 mm; - temperature interval – from 80 to 370 K; - magnetic field interval – from 0.02 to 2 T.

Request for a quoteResults for

Thermally conductive ceramics - Import exportNumber of results

14 ProductsCountries

Company type