- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special welding

Results for

Special welding - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

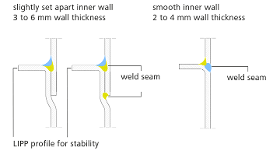

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

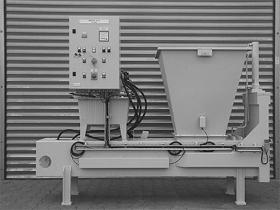

The Nova cooling tanks by FESSMANN convince with their highquality processing and special hygiene designs. This means Allround jointfree welding, use of special antidirt edges and a tank bottom inclined towards the drain. This way, dirt deposits are a thing of the past and cleaning becomes child's play! Unique heat insulation ensures best efficiency Volume can be chosen between 300 – 1000 l Hygienic stainless steel design with antidirt edge Delivery in prefabricated construction considerably shortens the assembly times

Request for a quote

ANTHERMO GMBH

Germany

Special parts In addition to our standard delivery program, we can also procure and deliver special / drawing parts for special applications. This applies to welding outlets, fittings as well as eyeglass blinds and drawing parts. Special know-how Together with our long-term partner companies, we have the necessary know-how to also manufacture unusual drawing parts.

Request for a quote

ANTHERMO GMBH

Germany

(Socked-Weld-Fittings) Straight from our warehouse We always have numerous versions of weld-in fittings (ANSI B 16.11) available in our extensive warehouse in Kamen. We can also supply you at short notice. We only deliver goods of European origin. 3 types of reducing inserts Insert reducers are available in three different types (see technical data sheet in the download area). Standards and special requests We supply weld-in fittings as standard in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply 9000 lbs and special materials if required. Technical specifications You can find more details, technical data and dimensions in our data sheet "Weld-in fittings" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

PIERON GMBH

Germany

Dimensions Depending on the required stamp power (material strength, material thickness, and part shape) Material All spring materials in soft and hard condition as well as quality steels with lower strengths and aluminum alloy and also special alloy Stainless steel up to 1900 N/m² Rubber-coated strip material Hardening Through external services Coating Fully or partly coated strip material In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Fully automated manufacturing of components and mounting Fully automated welding Contact springs with contact rivet Bushes clinched, welded, and open Special processing like thread cutting, screw mounting, and rivets feasible Special packaging in blister pack, trays or magazines Rapid prototyping

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse We have around 150 different versions of Socket Weld Outlets (ANSI B 16.11 / MSS SP 97) in our extensive warehouse in Kamen. We can deliver to you at short notice at any time. We only deliver goods of European origin. Standards and special requests We supply socket weld outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply special materials on request. Furthermore, socket weld outlets differentiate between reduced and full branches. Express service We can deliver socket weld outlets in stock to the customer within Germany the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service. Technical specifications More details, technical data and dimensions can be found in our data sheet “Socket weld outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse Approx. We keep 300 different versions of welding outlets (ANSI B 16.9 / MSS SP 97) in our extensive warehouse in Dortmund. We can also supply you at short notice. We only deliver goods of European origin. Standards and special requests We deliver welding outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) and in all common materials. If required, we can also supply special materials. In the case of welding outlets, a distinction is also made between reduced and full waste. Express service We can deliver welding outlets in stock within Germany to the customer the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. High performance filter bag made of needle felt in PP or PES (welded/sewn version) Longer lifetime Higher dirt absorption capacity Fully welded seams Special bag filter seal Full compatibility with the entire FTJ filter housing program Production according to the highest quality standards

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit is the technological market leader for grinding applications. Our adhesive grinding discs with velcro fastening for dual-action sanders exemplify this. Tyrolit FAST CHANGE (TFC) offers a range of discs for machining almost all materials. For optimal material removal, we provide discs with varying hole numbers that can be quickly mounted on Tyrolit backup pads via velcro. Our product range includes various grit sizes, enabling applications from coarse to fine on metals, wood, paints, composites, and more. Tyrolit adhesive grinding discs, with strong paper or film backing and zirconia alumina oxide, ensure high aggressiveness and long life. Active coolants provide a cool, clean finish, ideal for removing small weld seams. Additionally, special film-backed discs offer better edge stability and stock removal, making them perfect for lacquers, paints, and composites. TFC backup pads provide added support, ensuring high efficiency and long lifetime for all tasks.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

KMC GROUP - MEKO METAL

Turkey

Fixed Systems Tracker Systems Our profiles; Standard and special open profiles Standard and special welded profiles Perforated and special section solar construction profiles Omega profiles

Request for a quote

KMC GROUP - MEKO METAL

Turkey

Minimum and maximum sheet thickness: 0.4 - 8 mm. Pipe production diameter Ø10 - Ø193 MM profileproduction range 10*10 - 150*150 galvanized profile production, re-coating the welding place with zinc,profile production in special sections in welded profile,drilling and cutting operations before or after profiledrawing. Bending and mechanical processes aftershaping. Shooting any desired brand on the profile. Profile cutting, drilling, bending, shaping and assemblyapplications.

Request for a quote

PORTPALLET

Portugal

Pallet in galvanized steel, welded. Specially developed to transport materials such as stones, marble, among others. Stackable and collapsible.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in the production of welded metal constructions tailored to customer requirements. The materials we use include steel, aluminum, and stainless steel. Our processes incorporate cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding. In collaboration with our partners, we also address surface finishing solutions, including powder coating, hot-dip galvanizing, electroplating, pickling, and passivation. We take pride in the quality and precision of our products, ensured by these technological innovations. With our focus on technological advancement, we are capable of meeting even the most demanding requirements of our customers.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

We provide welding of classical steel, but our specialization is welding stainless steel. We provide point welding, TIG welding, and MIG / MAG welding. Due to subsequent grinding with quality tools, our products meet the highest quality Material possibilities: • The maximum thickness of the elements to be welded is 5mm + 5mm Is your question more comprehensive or more general? Send us an email at biuro@web-elektron.pl and we will propose the most suitable solution after its processing.

Request for a quote

AVK REWAG

Netherlands

High MIG welding robot connection. Specially designed NBR rubber with progressive sealing wafer construction (optional EPDM). Lug construction sealing gasket ensures proper fixation and prevents tension in rubber. Bolts are Teflon coated. Saddle and stirrup are fully passivated. Completely made of stainless steel AISI 304 (optional AISI 316). Branch BSP / Polsafe (optional NPT). Water PN10 Gas 300 mBar Stirrup is protected against contact corrosion by rubber.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BASE GROUP SP Z O.O.

Poland

We have been specializing in welding of construction for marine and other products used in the maritime sector for years. Structures manufactured for the maritime sector are of high quality and in accordance with the international standards. We have produced machines called scrubbers – fume scrubbers used in maritime industry and many other products customized according to our customers’ projects. We manufacture high quality steel constructions for marine in accordance with the international standards: ISO 3834-2, EN 1090-2 and EN 1090-3, Offshore Standard DNV-OS-C401 and ISO 9001:2015, ISO 14001:2004.

Request for a quote

ORBITEC GMBH

Germany

Gas-cooled weld head for applications with extreme narrow space requirements as e.g. in the semiconductor industry. Specially designed to weld micro-fittings. Unique construction, including specifically directed gas routing to improve gas coverage and material selection resulting in a high duty cycle even without water cooling. — Extreme narrow / compact design — Simple design allows easy to maintain — Weld Head compatible with control element (start/stop kit with status display) — Arc Machines Model 9-500 cassettes will fit too

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

Our welders are certified for welding using the MIG/MAG process. Manual welding capability up to 450A, and welding under flux up to 900A. We specialize in welding unique and demanding products.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products employs a wrought powder metallurgical process to manufacture custom gauge and width strip materials used as the outside sheathing of flux cored wire and metal cored welding wire. Advantages Our high purity process allows production of wire sheathing materials with significant advantages for flux cored welding wire producers, compared to a conventional casting process. These include: Very high ductility Tight and repeatable chemistry control Availability of unique and custom chemistries High purity material for improved tool and die life Corrosion, wear and high temperature resistant Short lead times and small batch sizes Find a consolidated listing of our metal sheathing materials in our Weld Wire Sheathing Brochure. Chemistry Control We tightly control the chemistry of the incoming raw materials to ensure that trace elements are kept to a very low level. Our wrought powder metallurgy process allows chemistry flexibility

Request for a quote

MR CO. LTD.

Ukraine

Aluminum alloys are among the materials characterized by poor weldability. Any experienced welder will confirm that to work successfully with aluminum, you need to have a lot of experience and know all the features of this metal. Technologically this process is quite complicated and a lack of experience can lead to manufacturing defects. Due to its high thermal conductivity, low melting point and the presence of a refractory oxide film, welding aluminum requires special equipment. TIG welding with shielding gas using aluminum alloy hard facing rods provides excellent joint quality.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Superior Tube is committed to improving healthcare options for patients, and to helping surgeons save lives. As such, we manufacture a range of specialized welded and seamless tubing products for various areas of the medical device industry, including cardiac stents. Stents are small, expandable tubes, usually made of metal mesh, and are used to treat narrowed or weakened arteries. In patients with coronary heart disease, stents are implanted in order to open narrowed arteries during a procedure called percutaneous coronary intervention, or angioplasty. Heart stents can also help relieve chest pain and aid in the prevention of heart attacks. Ever since our tubing was used in the earliest cardiac stent implants in 1987, Superior Tube has been an industry leader in the manufacture of implant grade tubing for both coronary and peripheral stents. Please note that we have a minimum order value of £10,000.

Request for a quote

TANAX TRUCKS

Slovakia

Our array of components for agricultural machinery. We specialize in manufacturing, welding, spray painting, and sandblasting each part to ensure it withstands the rigors of farm use. Our dedication shines in the durability and performance of our components, confirming our role as a trusted supplier for agricultural leaders.

Request for a quote

NAIDEKA, UAB

Lithuania

Tools making: dies, stamps, moulds, special devices, jigs, tool parts. Welded constructions in steel, stainless steel, aluminium, building structures, production of non-standard equipment.

Request for a quote

BEHA INNOVATION GMBH

Germany

The BEHAbelt EErgo paddle welding tools were specially developed for the connection of PU and TPE profiles or flat belt strips. · Strong, fiberglassreinforced ergonomic housing. · Unique control panel for onehanded operation. · No adhesion of PU and TPE materials, thanks to Tefloncoated welding paddle.

Request for a quote

COMPANY TOR

Russia

The VIKING-500 PRO semiautomatic welding machine has two-piece design, is designed for power supply from a three-phase 380V network and produces 500A at a load of 60%. The design feature consists in a separate feeding mechanism that can be removed from the source to a control cable length of up to 15 meters. The device heats up the product to a minimum, which allows you to work with thin metals. An important feature is the presence of a two-shaft motor for the wire inch (four rollers), which significantly improves the stability and smoothness of the welding material feeding. Special software functions significantly increase the performance factor of the device. ... Key features of VIKING MIG 500 PRO: - digital control of the device; - advanced software settings; - dot welding mode 2T and 4T; - setting of a smooth drop of the termination current; - adjustable inductance; - forced gas purging; - forced wire inch; - the presence of a 36 V socket (for connecting a CO2 gas heating regulator

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

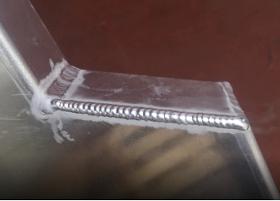

The welding process is one of the core ways in which we manufacture precision tubes. Our high-quality tubing starts off as a flat strip of metal. The strip is formed into a tube through a series of rollers and the join, also called the seam, is then welded together. Welded Processes Special non-destructive testing methods – including eddy current, ultrasonic and pressure testing - are used to ensure a consistent weld. Just like with seamless manufacturing, welded tubes can be drawn down by plug drawing or sinking. This method can be used to create very long lengths of coiled tube, these can also be measured during coiling using a laser measurement. The main welded tube manufacturing processes used are strip welding and cold drawing, but other important processes in between, or at the end of the drawing process, include Please note that we have a minimum order value of £10,000.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quoteResults for

Special welding - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Welding, soldering and brazing - equipment and supplies (4)

- Welding work - steels and metal (3)

- Laser - cutting and welding machines (2)

- Filtering equipment and supplies (2)

- Industrial robots (2)

- Pipes, bent - ferrous metal (2)

- Steels and metals - machining (2)

- Tanks, metal (2)

- Welding, electric - equipment and supplies (2)

- Steels and metals - welding and brazing (1)

- Abrasives, mechanical (1)

- Agricultural machines and accessories (1)

- Anti-theft systems and equipment (1)

- Autogenous welding machines (1)

- Bag filling machinery and equipment (1)

- Chemistry - laboratory products (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Copper wires and cables (1)

- Disposable medical and surgical articles (1)

- Drawing - steel and metals (1)