- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special welding

Results for

Special welding - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The Nova cooling tanks by FESSMANN convince with their highquality processing and special hygiene designs. This means Allround jointfree welding, use of special antidirt edges and a tank bottom inclined towards the drain. This way, dirt deposits are a thing of the past and cleaning becomes child's play! Unique heat insulation ensures best efficiency Volume can be chosen between 300 – 1000 l Hygienic stainless steel design with antidirt edge Delivery in prefabricated construction considerably shortens the assembly times

Request for a quote

ANTHERMO GMBH

Germany

Special parts In addition to our standard delivery program, we can also procure and deliver special / drawing parts for special applications. This applies to welding outlets, fittings as well as eyeglass blinds and drawing parts. Special know-how Together with our long-term partner companies, we have the necessary know-how to also manufacture unusual drawing parts.

Request for a quote

ANTHERMO GMBH

Germany

(Socked-Weld-Fittings) Straight from our warehouse We always have numerous versions of weld-in fittings (ANSI B 16.11) available in our extensive warehouse in Kamen. We can also supply you at short notice. We only deliver goods of European origin. 3 types of reducing inserts Insert reducers are available in three different types (see technical data sheet in the download area). Standards and special requests We supply weld-in fittings as standard in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply 9000 lbs and special materials if required. Technical specifications You can find more details, technical data and dimensions in our data sheet "Weld-in fittings" in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

PIERON GMBH

Germany

Dimensions Depending on the required stamp power (material strength, material thickness, and part shape) Material All spring materials in soft and hard condition as well as quality steels with lower strengths and aluminum alloy and also special alloy Stainless steel up to 1900 N/m² Rubber-coated strip material Hardening Through external services Coating Fully or partly coated strip material In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Fully automated manufacturing of components and mounting Fully automated welding Contact springs with contact rivet Bushes clinched, welded, and open Special processing like thread cutting, screw mounting, and rivets feasible Special packaging in blister pack, trays or magazines Rapid prototyping

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse We have around 150 different versions of Socket Weld Outlets (ANSI B 16.11 / MSS SP 97) in our extensive warehouse in Kamen. We can deliver to you at short notice at any time. We only deliver goods of European origin. Standards and special requests We supply socket weld outlets in two pressure levels (3000 lbs and 6000 lbs) and in all common materials. We can also supply special materials on request. Furthermore, socket weld outlets differentiate between reduced and full branches. Express service We can deliver socket weld outlets in stock to the customer within Germany the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service. Technical specifications More details, technical data and dimensions can be found in our data sheet “Socket weld outlets” in the download area. We will be happy to provide you with information on special dimensions and custom-made products on request.

Request for a quote

ANTHERMO GMBH

Germany

Straight from our warehouse Approx. We keep 300 different versions of welding outlets (ANSI B 16.9 / MSS SP 97) in our extensive warehouse in Dortmund. We can also supply you at short notice. We only deliver goods of European origin. Standards and special requests We deliver welding outlets in different wall thicknesses (STD, XS, S 160 & XXS and special wall thicknesses) and in all common materials. If required, we can also supply special materials. In the case of welding outlets, a distinction is also made between reduced and full waste. Express service We can deliver welding outlets in stock within Germany to the customer the next day if the order is received by 11.00 a.m. Simply specify when ordering if you would like to use this express service.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. High performance filter bag made of needle felt in PP or PES (welded/sewn version) Longer lifetime Higher dirt absorption capacity Fully welded seams Special bag filter seal Full compatibility with the entire FTJ filter housing program Production according to the highest quality standards

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

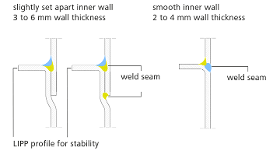

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

ORBITEC GMBH

Germany

Gas-cooled weld head for applications with extreme narrow space requirements as e.g. in the semiconductor industry. Specially designed to weld micro-fittings. Unique construction, including specifically directed gas routing to improve gas coverage and material selection resulting in a high duty cycle even without water cooling. — Extreme narrow / compact design — Simple design allows easy to maintain — Weld Head compatible with control element (start/stop kit with status display) — Arc Machines Model 9-500 cassettes will fit too

Request for a quote

BEHA INNOVATION GMBH

Germany

The BEHAbelt EErgo paddle welding tools were specially developed for the connection of PU and TPE profiles or flat belt strips. · Strong, fiberglassreinforced ergonomic housing. · Unique control panel for onehanded operation. · No adhesion of PU and TPE materials, thanks to Tefloncoated welding paddle.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Plastic-coated steel cablestrands are cut to length using a special shear cut module and then stripped with the cutting module of the AM3500 without the wires "jumping open".Bare steel cable wires are transported by the modified AM 3500 directly to the special cutting machine, which is coupled between the AM 3500 and the material stacker and which cuts the material to length by a thermal process. Due to the special electric welding process used here, the individual wires do not twist up during cutting, and a smooth rope start and a smooth rope end without thickening are produced. Long steel cable wires/strands are placed in a tray after processing, while short pieces of material fall down a chute into a collecting container. With the high-performance solution developed by Metzner, the customer can process different types of material in different processes. Further advantages of the machinery are high precision, high quality, an increase in productivity and lower personnel costs.

Request for a quote

ALPHA LASER GMBH

Germany

The mobile laser welding machine ALFlak is particularly suitable for laser deposition and contour welding on large machine components, design components as well as on injection moulds and tools The sophisticated movement mechanism of the ALFlak enables you to work comfortably on large components - you can even immerse in deep, bulky shapes with the slim laser arm. With long weld seams, the ALFlak takes advantage of its large travel axes. A weld seam with a length of up to 500 mm is possible without settling - manually or according to a specified program. Welding can be done in manual mode, semi-automatic or fully programmed. The use of an automatic wire feeder or a rotary axis is also possible. It is the versatile possibilities for mobile welding that make it a very special welding system.

Request for a quote

FIBALON GMBH

Germany

The already simple application of our innovative polymer fiber filter FIBALON® is made even easier with our new FIBALON®rope. 8, FIBALON® nets arranged like on a rope of pearls for almost all common pool filters. The filter material can be removed and replaced with just one handgrip. Our special mesh ensures optimal alignment and orientation of the FIBALON® filter balls during the filtration process. In addition, the net acts similarly to a protective shield. By means of a special welding technique, both the net and the welding seams, are chemically- and in particular chlorine-persistent. Due to the use of the new FIBALON®rope, the application of our backwashing grid is obsolete. For FIBALON®rope we also use our optimized fiber combination and other process innovations offers an incomparably high selectivity of 8 microns. All advantages of FIBALON®3D can be adapted and it promises an even easier handling.

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Eisele vertical pumps have proved themselves thousands of times and are superior in quality and performance. Key data: Forced supply through the screw impeller Inlet nozzle and screw impeller with special hard-faced welding Similar method of working as with a shredding machine Absolutely dry-running safe Highly wear resistant mechanical seal, oil bath lubricated With / without mixing nozzle Can be rotated by 235° VM: with three-phased motor that can be overloaded 11.0 / 15.0 / 18.5 / 22.0 kW with conveying capacity up to 6,000 l/min VG: with EISELE angular gear for tractor drive und conveying capacity up to 12,000 l/min Eisele vertical pumps have proved themselves thousands of times and are superior in quality and performance. Many different application possibilities can be perceived with the high-performance pumps.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAWASAKI ROBOTICS GMBH

Germany

Kawasaki's BA Series and RA Series arc welding robots use the latest arc welding technology to compete with the quality of a trained human welder. The robots are equipped as standard with special arc welding software that allows quick and easy programming of the process path. An adaptive welding function is available to change the position of the robot, the shape of the weld seam and the speed during welding in the case of variable weld connections. Their built-in intelligence, flexibility and high accuracy make Kawasaki's arc welding robots ideal for a wide range of arc welding applications.

Request for a quote

TKD KABEL GMBH

Germany

TKD | 07 Rubber Cables Flexible Power supply & Control Cable for applications with high mechanical requirements. ( e.g. automotive industries, shipbuilding, machine tool building mining and industries, in quarries and on construction lots.) - Light and middle rubber-sheathed flexible cables - Heavy rubber-sheathed flexible cables - Welding cables - Special rubber cores - for permanent use in water Excerpt of versions: > flat & round > shielded, unshielded > with and without supporting element > UV-resistant, Oil-resistant Excerpt of products: H05RR-F - H05RN-F - H07RN-F - H07RN-F PREMIUM - NSSHÖU H01N2-D - H01N2-E - NSGAFÖU - NSHXAFÖ

Request for a quoteResults for

Special welding - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Welding, soldering and brazing - equipment and supplies (3)

- Industrial robots (2)

- Pipes, bent - ferrous metal (2)

- Tanks, metal (2)

- Laser - cutting and welding machines (1)

- Filtering equipment and supplies (1)

- Welding, electric - equipment and supplies (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Drawing - steel and metals (1)

- Electric cables (1)

- Mechanical engineering - custom work (1)

- Storage tanks (1)

- Swimming-pool maintenance products (1)