- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silicon-nitride

Results for

Silicon-nitride - Import export

PRECISION CERAMICS

United Kingdom

Silicon Nitride (Si3N4), just like its close family relation silicon carbide, is one of the toughest technical ceramics available. Over the years it has been successfully used in a wide and interesting field of applications ranging from automotive engine components to roller bearings for the most exclusive skateboards (right).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride (Si3N4) is a high-melting-point material with high fracture toughness and excellent thermal shock resistance, It is considered to be one of the few monolithic ceramic materials that can withstand severe thermal shock and thermal gradient generated by hydrogen and oxygen rocket engines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

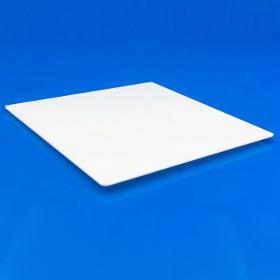

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Si3N4 Silicon Nitride Tube Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

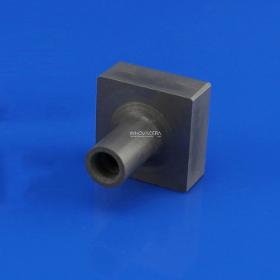

The protective tube of silicon nitride material has high thermal conductivity, high temperature resistance, corrosion resistance,non-wetting with molten metal, and electrical insulation, making it the best choice for heating body protection tubes. The advantage of the immersion holding furnace is very obvious, and in order to achieve the immersion of the heating element into the molten metal, it is necessary to have a protective tube which can protect the heating element well. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride guide rollers are more resistant to high temperature, high hardness, high toughness, impact resistance and oxidation resistance. At the same time, silicon nitride guide rolls are oil-free, self-lubricating, low in density and light in weight. The service life is more than ten times that of the alloy guide roller. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

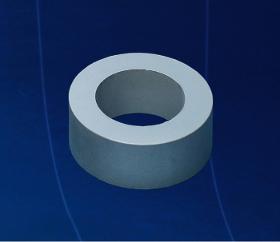

Silicon nitride magnetic rings are mainly used to protect high voltage electrodes and are widely used in the photovoltaic industry.Heat shields and magnetic rings, as well as ceramic rings, are collectively referred to as electrode shields.Silicon nitride electrode protection cover mainly uses silicon nitride insulation, heat resistance and corrosion resistance.Compared with the protective cover of quartz and alumina which is still in use today, the service life of the silicon nitride electrode shield is more than 10 times, and it will not be electrically broken down during use, and will not be heated, nor will it be heated. Will be eroded away. Due to its own stability, in the use of photovoltaic reduction furnaces, the collapse rate of non-human factors is greatly reduced. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride heat shields and magnetic rings are mainly used to protect high voltage electrodes and are widely used in the photovoltaic industry.Heat shields and magnetic rings, as well as ceramic rings, are collectively referred to as electrode shields.Silicon nitride electrode protection cover mainly uses silicon nitride insulation, heat resistance and corrosion resistance.Compared with the protective cover of quartz and alumina which is still in use today, the service life of the silicon nitride electrode shield is more than 10 times, and it will not be electrically broken down during use, and will not be heated, nor will it be heated. Will be eroded away. Due to its own stability, in the use of photovoltaic reduction furnaces, the collapse rate of non-human factors is greatly reduced. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride grinding discs, impeller blades are widely used in the field of powder grinding and are used as chassis. Because silicon nitride ceramics are very hard, second only to diamonds and other materials, there is almost no loss during thegrinding process, and the impurities brought into the product are also minimal. Although silicon nitride is a ceramic product, it has a good crystal structure, and the silicon nitride spherical product can well retain the crystal structure, so that the stress can be dispersed and the various metal ores can be broken. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Ball is made of the hot isostatic pressing and sintering furnace and has the properties including high strength,high wear resistance,high temperature,corrosion,acid and alkali resistant,long-term using in the sea,good electrical insulating ect. The precision Si3N4 Ceramic Ball of Innnovacera produce is widely used in a a variety of high-precision, high-speed / ultra-high-speed bearings, vacuumbearing, high / low temperature bearing, non-magnetic bearing.It is also as the measurement ball used in chemical valve,high temperature valve,meter valve ect.The field of the application involve chemical, metallurgical, medical, food, oil, electronics,aerospace,ect. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

NORELEM FRANCE

France

The combination of excellent material properties is a special feature of silicon nitride (Si3N4). These include high resiliance and stability, excellent wear properties and good chemical resistance.

Request for a quote

NORELEM FRANCE

France

Ceramic bearings Si3N4. Bearing cage PTFE. For most applications Si3N4 is the preferred material for ceramic bearings. Silicon nitride bearings are light, very hard and highly wear resistant. High and ultrahigh performance bearings are used in e.g. aerospace technology, metal production industries (high application temperatures), machine manufacturing, chemical industries (chemically aggresive substances), pharmaceutical and medical industries, semiconductor and biotechnology (clean room enviroments which may not be contaminated by lubricants). On request Special version with PEEK ball cage. Without ball cage.

Request for a quote

PRECISION CERAMICS

United Kingdom

Like oxides and nitrides, Silicon Carbide (SiC) is a very hard-wearing material, again requiring diamond-grinding methods to process once fired. Although not exclusively, carbides are used mainly for applications in which physical wear is a major consideration. They are amongst the hardest materials available.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

AMB Ceramic Substrate is a method to realize the bonding of ceramic and metal by reacting a small amount of active elements Ti and Zr in filler metal with ceramics to form a reaction layer which can be wetted by liquid filler metal. Advantage: The combination is achieved by chemical reaction between ceramic and active metal solder paste at high temperature, so its bonding strength is higher and reliability is better. Disadvantage: The reliability of AMB process depends largely on the composition of active filler metal, brazing process, brazing layer structure and many other key factors。 Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um; >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Balls are widely used on bearings with extreme performance requirements, such as: High-speed bearings, high precision bearings, vacuum bearing, high / low-temperature bearing, non-magnetic bearing, high precision ball screw; it is also used as valve ball, measuring ball for the chemical pump, heat pumps, metering pumps. Its excellent properties including: Good corrosion resistance withstands attacks from harsh chemicals and environments. High-Temperature Hardness is twice that of steel, Silicon nitride ceramic balls retain their strength and hardness up to 1800 degrees F.Lightweight, silicon nitride ceramic balls’ density is 3.20g/cm3 and weighs 45% less than steel which reduces centrifugal force, skidding and wear under high speed and acceleration, so greatly extending the service life. Superior Surface Finish is conducive to improving working speed and reach higher accuracy.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Material of Boron Nitride Ceramics: Pyrolytic Boron Nitride: 99.99% Boron Nitride* 99 Boron Nitride: Boron Nitride + Boric Oxide (B2O3) CABN: Boron Nitride + Calcium Borate ALBN: Boron Nitride + Al2BO3 ZRBN: Boron Nitride + Zirconium Oxide + Boric Oxide (B2O3) ZABN: Boron Nitride + Zirconium Oxide + Aluminum Nitride + Al2BO3 SCBN: Boron Nitride + Silicon Carbon + Al2BO3 Processing of Boron Nitride Ceramics: 1.Hot Pressed Sintering 2.Chemical Vapor Deposition

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our all-ceramic bearings are characterised by their high corrosion resistance to seawater and various chemicals. They are therefore used, for example, in the chemical industry, in the food and beverage industry, in shipping and in chlorine systems. We can manufacture our full ceramic ball bearings with rings and balls made of zirconium oxide (ZrO2) or silicon nitride (Si3N4), depending on the application. They are available with full balls or with cages made of PEEK or PTFE. The runout accuracies common with precision steel bearings cannot be achieved with all-ceramic bearings, so speed values have to be reduced. Ceramic materials are harder than steel, but also more brittle. Silicon nitride in particular has a low elongation at break and tends to break under tensile stress without prior plastic deformation. We take this into account when selecting the optimum bearing solution for your specific requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia ceramic disc plates are characterized by high toughness, high bending strength, high hardness and high wear resistance.Zirconia ceramics have a dimensional hardness of 11.5GPa, a density of 6.0g/cm3 and a compressive strength of 2100MPa. Zirconia ceramics are widely used as ductile ceramics with fracture toughness up to 8.0 mpAM1/2. Advantages: smooth surface (easy to clean), good toughness, impact resistance, high hardness, wear resistance, low thermal conductivity (heat insulation), generally no insulation and high temperature resistance Applications: machinery, optical fiber, cutting tools, medical, food, chemical, aerospace Ceramic material composition: - - 95%--99.99% Alumina (Al2O3) - - Silicon Carbide · Silicon Nitride - - TTZ: Magnesia partially stabilized Zirconia (ZrO2) - - YTZP: Yttria partially stabilized Zirconia (ZrO2) - - ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ceramic Screw and Bolts Ceramic screw and nuts refers to the ceramic screw is made of zirconia, alumina, silicon nitride and other materials of screw products,which has more stable physical stability and chemical stability, physical stability is mainly manifested in high and low temperature resistance, insulation, antimagnetic, wear resistance and other aspects; Chemical stability of the main surface in corrosion resistance, oxidation resistance. However, because it is a hard and brittle material, its mechanical properties can not be compared with metal materials. Of course, with the progress of material technology and the improvement of product structure,this gap is gradually narrowing. > Alumina Zirconia Ceramic Insulation Fastener Bolt And Screw > Thread Specification:M3-M24 > Screw cap:Hexagonal socket, flat headl > Plain Ceramic Hex M3 x 10mm Set Screwl M3 × 10mm > Screw cap:Hexagonal socket, flat headl > Plain Ceramic Hex M3 x 10mm Set Screwl M3 × 10mm

Request for a quoteResults for

Silicon-nitride - Import exportNumber of results

35 ProductsCompany type