- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- services for electronics

Results for

Services for electronics - Import export

SEACOMP

United States

Contract Manufacturing by SEACOMP Get your concept to physical product with our electronics manufacturing services. Use our engineering team to get your design ready for mass production or let us take your perfectly designed product and build it at scale. We help launch electronic devices for home automation, industrial controls, consumer products, and medical devices. Manufacturing is completed in our wholly-owned China facility that is ISO 13485 certified. Our production capabilities include: - PCB Assembly, Surface Mount (SMT), Through Hole Assembly - Wave Soldering - Reflow Soldering - Plastic Injection Molding (vertical and horizontal) - Ultrasonic Welding - Cable Assembly and Over-Molding We also provide the finished assembly of your product before it is shipped anywhere in the world: - Laser Marking - Pad Printing - UV Ink Curing - Label Printing - UV Light Metering - Box Build Assembly - Bulk or Retail Packaging - Warehousing Contact us to learn more.

Request for a quote

TROTEC GMBH

Germany

The B300 unit offers the best humidification in its segment. The B2300 mates superior appealing design with class leading technology to render a revolutionary humidifier that is purposed to the highest grades while combining unobtrusively into its stylish ambiance. There are however a few who would agree that the fetching form of the B300’s and the modern design even make it a masterpiece in its own right. Needless to say, the B300 is not just a glamorous humidifier from the outside, it is an extremely efficient piece of technology that is engineered to cater to the needed of extremely critical users who has a precise perspective of what they want when they decide to invest in a product that is made in Germany. Practical advantages: High-performance humidifier with multistage fan and large-sized water tank UV lamp for the effective disinfection of the service reservoir Fully-automatic operation electronic control via moisture sensor

Request for a quote

SIKO GMBH

Germany

High-performance compact actuator for complex positioning jobs Space-saving, easy mounting. Through hollow shafts up to max. ø14 mm. Brushless 50 W, 24 V EC motor with long service life. Integrated power and control electronics with inverse polarity and overload protection. Integrated absolute position encoder on the output shaft. Integrated CANopen or Profibus-DP with M12 component mounting technology. Integrated RS458/SIKONETZ5 interface with M8 component mounting technology. With IO-Link

Request for a quote

SIKO GMBH

Germany

Fieldbus Profile AG03/1 Fieldbus: Space-saving, easy mounting Through hollow shafts up to max. ø14 mm Brushless 50 W, 24 V EC motor with long service life Integrated power and control electronics with inverse polarity and overload protection Integrated magnetic absolute position encoder on the output shaft Integrated CANopen or Profibus-DP with M12 component mounting technology Integrated RS458/SIKONETZ5 interface with M8 component mounting technology

Request for a quote

NSGATE

Russia

Electrical and electronic equipment mounted inside a cabinet generate heat that raises the temperature internal air. Over time, the ever increasing heat can cause sensitive devices to malfunctions. Additionally, heat accumulation can cause circuit breakers to trip which can result in system shut down. Fan filter units are used for enclosure climate control to dissipate heat from within the enclosure to prevent the premature failure of the equipment inside it. It helps to increase an operational reliability and a service life for electrical and electronic systems. Filter fans will cool enclosures to a level slightly above the ambient temperature outside the cabinet. To cool enclosure contents, the fans draw filtered ambient air into the cabinet. At the same time, the heated air within the cabinet is blown out an exhaust. The exhaust is also filtered which creates airflow resistance and a slightly higher pressure inside the enclosure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IRZ (IZHEVSKIY RADIOZAVOD)

Russia

The company is opened for cooperation in terms of Electronics Manufacturing Services / Licensed Production / Products Localization for the Russian market. The company’s competence covers all production activities enabling the full cycle of product development, from an idea to serial production based on LEAN manufacturing principles. Both small batches and serial products with equally high quality can be produced without minimum order quantity limit. Our capabilities: R&D, industrial design; EEE parts procurement and testing; PCB production; SMT/THT; Mechanical processing; Cables and winding parts production; Hybrids production; Assembly production; Testing of finished products.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. At RAFI Eltec, we test the quality of our products across all manufacturing processes. By performing individual tests and integrating fully automatic tests in combined assembly and testing lines, we achieve targeted and effective test cost reductions. For this purpose, we insist on the most cutting-edge technologies and high-quality equipment. Testing technologies - Pull test for chip-on-board - Automatic optical inspection - Flying probe - In-circuit test - Boundary scan test - Function test - Burn-in test and run-in test - Temperature shock test - Temperature humidity test You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs. You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Even if the production process uses NoClean fluxing agents, special requirements sometimes call for a special cleaning process: with our state-of-the-art ultrasonic cleaning system, we reduce ionic residual contamination to a minimum. As a result, the cleaned assemblies can be quickly and safely further processed. Our focuses: - Assembly cleaning - Checking for assembly cleanliness You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

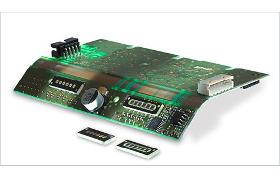

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Efficient production processes and reliable execution of the overall implementation are characteristic for RAFI Eltec. As a result of our many years of experience in energy measurement technology and in radio and network applications, we have accumulated unique production and testing expertise. This is also naturally to your advantage in regard to the final assembly of your devices. Final assembly - Assembly presses and screw fittings - Ultrasonic welding - Adhesive robots - Semi-automatic and fully automatic assembly - Automated testing - Laser or inkjet printing technologies - Leak tests - Box build You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Whether with a mini-wave or a Wörthmann wave, we deliver customary RAFI Eltec quality on our automatic soldering equipment even for wired assemblies. We apply various technologies here – coordinated to each individual project. Our focuses: - Wired assembly - Wave soldering (ROHS-compliant or leaded) - Automated selective soldering - Lift-dip soldering (multi-wave) - Manual soldering - Assembly - Visual inspection You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

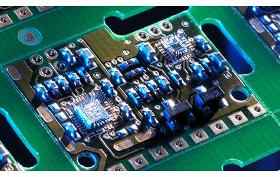

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. RAFI Eltec operates 5 fully automatic SMD high-speed, precision assembly lines with nitrogen reflow soldering technology. Our focus: - BGA, µBGA, CSP - QFN, Finepitch - 0201 - Novel components - Package-on-package - Automatic optical inspection Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs.

Request for a quote

UKRAINIAN SCIENTIFIC RESEARCH INSTITUTE COMPUTER TECHNOLOGY

Ukraine

SMT & THT assembly, functional testing, conformal coating selective application, assembled PCBs automated printed circuits cleaning, programming and functional testing of electronic units, setting up and adjustment of electronic units, case assembly, PCB design.

Request for a quote

INTEGRAL COMPLEX SYSTEMS

Ukraine

We carry out a full cycle of development of electronic devices: supply of electronic components, stencils and printed circuit boards, design of electronics, redesign of finished devices. Applying the principles of lean production, we achieve a price reduction while maintaining a high quality of services. Due to quality control at all stages of production, we have the reject rate less than 0.5% (at observance of all requirements to the order). Operative daily planning allows us to achieve maximum efficiency in the use of working time. Thanks to that, in the presence of all the equipment in the warehouse, we can take the order to work during the day from the moment of order. We have our own high-tech equipment, and offering good quality with competitive assembly cost.

Request for a quoteResults for

Services for electronics - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Electrical & Electronic Components (6)

- Automation - systems and equipment (1)

- Control boxes - electric (1)

- Electric and electronic components - machines for manufacturing (1)

- Electronics - import-export (1)

- Engineering - industrial contractors (1)

- Humidifiers, air (1)

- Import-export - medical and surgical equipment (1)

- Medical and surgical instruments (1)

- Printed circuits (1)