- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic drives

Results for

Pneumatic drives - Import export

HASPA GMBH

Germany

These are flexible shafts with cylindrical pin or thread to connect to: Drilling machines, pneumatic motors, lathes, cutters, straight grinders, angle grinders, other electric- or pneumatic driving units

Request for a quote

FÖHRENBACH GMBH

Germany

The machine structure with solid base plate is extremely compact and stable. All necessary components are integrated in the machine housing: mechanical axes, pneumatic components, control with drive electronics and mounted 12 "touch display. Depending on the desired version, the F-Décor 305 can produce surface patterns like circular grainings, côtes de Genève, engravings or decorative millings on mechanical watch parts. The machine guarantees high precision and high productivity. The F-Decor 305 is delivered ready for connection with either 1 or 2 working spindles.

Request for a quote

FERPLAST SNC

Italy

Special sealers ME 455/605 VAD with air suction system (max 80%) suitable for volume reduction and better preservation of products. The machine is equipped with a double sealing bar with a sealing width of 5 mm, an electric pedal drive and pneumatic cylinders, mobile nozzles for air intake, an adjustable timer for suction, sealing and cooling. The ME 4510/6010 VAG model with a ATM gas injection system is also available. This variant is equipped with a double sealing bar with a 10 mm sealing width, electric pedal drive, mobile nozzles for air intake and gas injection, adjustable timers for suction, intake, sealing and cooling.

Request for a quote

KUZEY GLOBAL

Turkey

Synchronized forming and cutting by tilting movable lower platen to 80 degrees Sheet pitched by double toothed chains and move on abrasion resistant slide plates; Lengthened pan design allows to reach optimum forming heat without using pre-heater machine Upper and lower Mold ; heats control by indivudial Thermoregulation device Fine adjustment for mold by electric drive. Traversing and tilting moving system of mould PLC for control the line operation and supervise working parameters Opportunity to set one or more forming cycles without cutting by pneumatic drive High production capacity with resistant to high speed Strong and vibration free main body Double inlet- outlet system for fast cooling by increasing water discharge. Energy analyzer which gives amount of the electric consumption Cutting adjustment possible by digital meter ,controlled by PLC. Plug asist motor

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

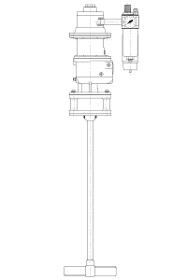

CRP-M - Pneumatic tote tank mixer for stainless IBCs The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CRP-E - Pneumatic tote tank mixer for plastic IBCs CRP-E Pneumatic tote tank mixer for plastic IBCs The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator. Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly. Explosion-proof mixers are also feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

AVM AUTOMATION

France

Motorization by integrated pneumatic cylinder Driving by rack and pinion system Adjustable mechanical stops Hydraulic shock absorbers Inductive sensors The wrist of a manipulator arm These rotary modules are, for example, the wrist of a manipulator arm, the turner of parts on a conveyor or the axis of rotation of an oscillating manipulator. In general, they rotate the gripper that grips the part. These modules are equipped with hydraulic dampers and inductive sensors, the rotation guidance is ensured by 2 ball bearings that allow this module to be used in all directions, even with offcentered payload. Rotary cylinder without angular play at end of stroke The end stops located under the plate allow there to be no shock in the rack and pinion transmission and no angular play at the end of the stroke. The absence of angular play allows use in assembly or precise positioning applications with 2 positions and the absence of impact in rack

Request for a quote

AVM AUTOMATION

France

Drived by integrated pneumatic cylinder Guided by 2 rods on ball bushings Adjustable mechanical stops Hydraulic shock absorbers Inductive sensors Flow limitation Compact and robust manipulator With a compact and very robust design, they are suitable for shortstroke movement where rigidity is necessary. They are often used in vertical or lifting modules in the design of pneumatic handling assemblies. For longer strokes, use the Type 37 manipulators. Several mounting directions possible Equipped with the same end plates and without exceeding of the cylinder at the end of the stroke, these compact manipulators can be fixed by the 2 end plates to have the movable central body, but they can also be fixed by the body, the rod cylinder can then be oriented up or down. Optimized end of stroke adjustments The fine adjustment of the stroke is done by mechanical stops without any intervention on the hydraulic dampers and the inductive detectors this saves time

Request for a quote

AVM AUTOMATION

France

Fixing by its sturdy end plate Drived by ISO pneumatic cylinder Guided by 2 rods on ball bushings Adjustable mechanical stops Hydraulic shock absorbers Inductive sensors Flow limitation Easier implementation Attached to the frame by its end thanks to a sturdy flange, they serve as a lifting module for assembly, loading and conditioning machines. By combining them with Type 37 linear manipulators, you can create 2axis ZX. Equipped with hydraulic shock absorbers, inductive sensors and flow limiters, these manipulators are ready to be installed and wired. Optimized end of stroke adjustments The fine adjustment of the stroke is done by mechanical stops without any intervention on the hydraulic shock absorbers and the inductive sensors this saves time, guarantees the reliability of the adjustment and ensures an optimal lifetime of these components. All these components are very common on the market and are very accessible, thus facilitating the maintenance

Request for a quote

AVM AUTOMATION

France

Pneumatic manipulator for handling drived by ISO pneumatic cylinder. Guided by 2 rods on ball bushings and end stroke adjustable by mechanical stops. Hydraulic shock absorbers, inductive sensors and flow limitation are supplied. Pneumatic pick and place and 3 axes handling systems The combination of 2 pneumatic manipulators makes it possible to create pick & place (XZ manipulators) for assembly, loading, packaging machines … By combining them with gantries it’s possible to realize 3axis cartesian pneumatic manipulators. Equipped with hydraulic dampers, inductive sensors and flow limiters, these manipulators are ready to be installed and wired. Optimized end of stroke adjustments The fine adjustment of the stroke is done by mechanical stops without any intervention on the hydraulic dampers and the inductive detectors this saves time, guarantees the reliability of the adjustment and ensures an optimal lifetime of these components.

Request for a quote

AVM AUTOMATION

France

Drived by pneumatic cylinder (ISO or rodless) Guided by rolling guides Adjustable mechanical stops Hydraulic shock absorbers Inductive sensors Flow limitation More than a rodless guided cylinder With their selfsupporting aluminum beam and being equipped with mechanical endofstroke stops, hydraulic shock absorbers, inductive sensors and flow limiters, these gantries are more than a cylinder without guided rod, they are real handling axes ready to install and wired. They are intended for the transfer of loads from 3 to 50 kg over strokes up to 1500 mm. Pneumatic Cartesian manipulators The mobile carriage, drived by a rodless cylinder (or a rod cylinder in short stroke to be more economical) allows to carry a perpendicular axis to create cartesian manipulators with 2 or 3 axes, with manipulators Type 37. Optimized end of stroke adjustments Pneumatic gantry with intermediate positions with through-travel

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Slide gate valve for solids flow on/off control, mainly used as an automatic valve for loss-in-weight feeder refill — Double acting pneumatic drive — Readily mounted 5/2 way solenoid valve Diameters - Different versions 80–400 mm (3.1–15.7 in)

Request for a quote

GENERAL MEASURE TECHNOLOGY LTD.

China

LF-5K is a linear feeder for granular materials and some powder materials. The vibratory feeding mechanism achieves multi-stage feeding. The pneumatic cylinder drives fast discharging. LF-5K linear feeder has a wide weighing range with high speed and high precision, which can be widely used in quantitative packaging machinery of grain, feed, chemical, rubber, and plastic industries.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRONG MAGNETS GMBH

Germany

Magnetic coupling is widely used in various fields such as magnetic drive of sealing vacuum of metering pump of polyurethane foamer, magnetic drive of pneumatic ball valve, magnetic drive of stirring reactor, etc. to prevent leakage of raw gas. Magnetic coupling is mostly used in high vacuum, high cleanliness, poisonous, corrosive, or harsh environment to transfer power from the driving shaft to the driven shaft. Because of the use of isolation seal sleeve, dynamic seal into static seal, zero leakage can be achieved.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Efficient positioning, assembly and handling of workpieces are key components in many manufacturing companies to meet growing cost pressures. Replacing pneumatic cylinders with electric linear drives can save up to 90 % of energy consumption. In addition, there are numerous advantages in motion control. IAI has the world's largest portfolio of electric actuators with 24 or 230 volt stepper or servo motors. The electric cylinders perform linear, rotary or gripping movements and are characterised by the uniquely compact design including motor and encoder as well the high quality. In addition to the standard version, electric cylinders are also available for cleanrooms and as IP-protected models for dusty or wet production environments.

Request for a quote

MEDEK & SCHÖRNER GMBH

Austria

The cable marker KS 442 C-FM is a high-performance marker specifically designed for high-speed gravure printing on hot plastic insulated wires and plastic jacketed cables in user selectable colors. Due to the extremely high precision of the machine’s drive system, the KS 442 C-FM ensures a non-slip operation and a reduction of the strain on the soft cable insulation to a minimum. Marking of text and numbers Tandem printing head Quick change of legend Print wheel drive up to and above 1200 m/min Exchangeable ink supply system STANDARD CONFIGURATION Tandem marking unit with synchronized drive. Integrated pneumatic printing station selector. Integrated control electronics with additional input for automatic switching via external contact closure. 1 set of dedicated ink wipers and guide rollers matching the specified printing discs. Replaceable ink supply module with ink tank, pump, cooler, filters, and ink flow fine adjustment valve.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The name delivers what it promises. The ultrasonic welding machine HiQ VARIO can be configured to completely suit the customer’s needs. A large number of pneumatic drive modules with different strokes and cylinder diameters are available, always including the reliable proportional valve technology by Herrmann Ultraschall.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The core of this ultrasonic welding machine is the patented pneumatic HMC drive concept. It combines the benefits of pneumatics with the dynamics of an electrical drive and allows for selection of any optional start point for the weld process. The SoftTouch mode protects the sensitive joining area of the plastic parts to be welded during contact of the sonotrode.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The machine is designed with pneumatic driving principle. According to the needs of users, it can be set to manual single flip work mode and automatic flip continuous work mode, two working modes, realize automation, simple operation, greatly reduce the operator's labor, improve productivity, save money time, labor saving, high efficiency and so on. Application: This series of vacuum packaging machines are suitable for vacuum packaging of food industry, kimchi, sauce products, soy products, seafood, frozen meat products and other materials to inhibit the reproduction of microorganisms such as bacteria, effectively avoid product oxidative mildew and spoilage, and prolong the time. Product shelf life or shelf life.

HORTON EUROPE GMBH & CO. KG

Germany

HT650 The HT650 On/Off Pneumatic Fan Drive engages only when cooling is needed, resulting in reduced horsepower and fuel consumption. In the off mode, the HT650 completely disengages. The HT650 is engine controlled, providing the best possible response time. When engaged, the HT650 can deliver the maximum torque required by high-airflow capacity fans, without slipping. Whether you're hauling a heavy load up a long grade in summer heat, or need heat to your cab in cold weather, the on/off fan control of the HT650 will perform under the most severe conditions. Benefits - High torque - Improved fuel savings - Increased available horsepower Applications - Heavy-duty trucks - Medium-duty trucks Related Products - WindMaster Fans Links - Order or View Literature - On-line Catalog - HT/S Advantage Training Manual

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Solenoid Valves Excessive heat and vibration are no match for the HG300 Solenoid Valve. Developed for the most extreme diesel engine applications, the HG300 is the toughest valve on the market. The HG300 provides reliable, trouble-free, on/off operation to protect your cooling system. The optional internal diode also protects your electrical system and ECM from potentially damaging voltage spikes. Horton backs the HG300 with a three-year/324,902 mile limited warranty — the longest in the industry! All HG300 Solenoid Valves come in a multipurpose 3-way configuration, which means they can be easily plumbed normally open or normally closed. This saves installation time and reduces inventory requirements. It's the ideal choice for any pneumatic fan drive installation. Related Products - DriveMaster Spring-Engaged Fan Drives - DriveMaster Reman Fan Drives & Repair Kits - DriveMaster Two-Speed Fan Drives - HT/S Advantage Air-Engaged Fan Drives - Advantage Reman Fan Drives & Genuine Horton Repair Kits - HT/S PolarExtreme Reman Fan Drives & HT/S or S Repair Kits Links - Order or View Literature - On-line Catalog

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD Handformer HF 100 for stretching, shrinking, notching, hole punching, edging and clinching. The HF 100 makes forming easy, as it does away with time-consuming hammer beating. The HF 100 is able to stretch and shrink sheet metal and profiles up to 1.5 mm (steel) or 2.0 mm (Aluminium) in thickness. The Handformer is a stationary machine with a throat depth of up to 100 mm, and is mainly used in trade workshops. Apart from standard forming tools, ECKOLD offers tool inserts for notching, hole punching and edging as well as for clinching. • Adjustable working height • Quick tool change • Tool storage trays • Stop for precision guidance of workpieces • Also available with PA 80 pneumatic drive unit For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD Kraftformer KF 170 PD - Universal forming machine for stretching, shrinking, reforming, curving, planishing, flattening, doming, straightening, punching, notching and clinching. The Kraftformer KF 170 PD with pneumatic drive is the most compact of all ECKOLD Kraftformers. The machine is designed for single or continuous stroke operation for forming steel sheets with a thickness of up to 2 mm. Operated in single stroke mode, the KF 170 PD is the ideal machine for reworking and adjusting tasks. It can be used for punching, notching and clinching. In continuous mode, the KF 170 PD allows for fast and easy forming. In single stroke mode, it caters for precision hole punching, clinching and reworking! For our Kraftformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Max. forming capacity Steel 400 N/mm²: 2.0 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.5 mm Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Domes produced with ECKOLD machines in automotive industry make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter). This offer includes: Dome embossing frame Embossings: 1 piece/stroke Embossing geometry: according to data set Drive: pneumohydraulic Mechanical interface: support stand Embossing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. We optionally offer hydraulic or servo motor drives as well as multiple embossings/stroke.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quoteResults for

Pneumatic drives - Import exportNumber of results

40 ProductsCountries

Company type

Category

- Cylinders, pneumatic (4)

- Metalworking - portable power tools (4)

- Automation - systems and equipment (3)

- Chemical and pharmaceutical industry - machinery and equipment (3)

- Packing and packaging - machinery and equipment (3)

- Forming - steels and metals (2)

- Surface treatment - machinery and equipment (2)

- Pneumatic systems and tools (1)

- Conveyor belts (1)

- Cutting - machine tools (1)

- Embossing machine tools (1)

- Ink jet printing (1)

- Magnets (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Meat choppers and grinders (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Package sealing machinery (1)

- Pad printing (1)

- Switch (1)

- Welding, plastics - machinery (1)