- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- monitoring and control equipment

Results for

Monitoring and control equipment - Import export

PRESERVATECH EUROPE SP. Z O.O.

Poland

Our filtration system is designed to work with our Mini One and PMCG units or as a Stand Alone system for filtering air delivered to the display case.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

LPHC are , an acrylic-aluminium made humidification chambers designed to work with our Mini One microclimate generator. LPHC is offered in two standard sizes and also can be built as a special order in different sizes by client request. The body is made of black acrylic with aluminium and front doors from clear acrylic. RH levels are controlled through the Mini One microclimate generator. UNDER CONSTRUCTION CUSTOM STAINLESS STEEL CHAMBERS We are also offering special order microclimate chambers build to client specifications. Those units are constructed from stainless steel and depend on client expectations. All aspects of microclimate can be controlled: relative humidity, temperature and low level of oxygen can be attained. Chambers with controlled relative humidity and temperature can be built with glass doors (as in photo). Units with modified oxygen have solid, special sealed doors. Low level oxygen is generated using nitrogen generator or liquid nitrogen.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

Device is sensing vibration and sending data to monitoring system.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

Sensing a wide spectrum of gases. Size and look depends on measured gas. Some have build in display. Specification on the right is for carbon dioxide. Ask for other.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

We are offering very wide spectrum of radio connected sensors. In addition to Humidity and Temperature, we also offer light, gas (Ozon, Oxygen, CO2 and more), air quality, vibration, level, noise, air pressure and more. All sensors are connected to the gateway and can be monitored through our online monitoring system.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

Our monitoring system is designed to allow users of our equipment to have access to current data 24hr. All devices, manufactured by Preservatech have on board WiFi connectivity which allows to connect with our monitoring server. COMPATIBLE EQUIPMENT Mini One PMCG Maxi One Maxi One -s Custom equipment designed and made by Preservatech RHT sensor Filter sensor (only alarm messages)

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

Because of the complexity of controlling both parameters, every project is designed according to dimensions, material of the case, target values as well as ambient extremes in temperature and humidity. Although we do not have standard, off shelf units we are offering: Maxi T – Large units to control temperature and humidity inside the medium size cases (5-10 cubic meters) where main generator is located inside the machine room or other technical area some distance from the display case. See below. Mini T – small, compressor based unit for installation under or behind the display case. This unit can work with venting type or cooling/heating panels system. Will work with our Mini One or sometimes PMCG units. Special, thermoelectric device for very small cases. Will work with our PMCG unit. Please note that controlling temperature and humidity requires some changes to display case design and its very hard if not impossible

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

Preservatech’s Maxi One constant volume humidity generator is a fully automatic positive pressure air supply device, designed to provide conservation-quality humidity control for museum display or storage enclosures. A single microclimate unit in a remote location (such as a machine room) can reliably maintain extremely stable humidity control and pollution abatement for an entire gallery of showcases. SUGGESTED APPLICATION: Use these units to supply air to multiple display cases, very large volume showcases, multiple storage enclosures or small archive rooms where: Energy cost savings of up to 50% are to be realized. Accurate humidity control in new or renovated galleries may be expensive or impractical. Existing air conditioning systems or building envelopes cannot maintain adequate humidity control.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

The Maxi One S constant volume humidity generator is an automatic, positive pressure humidity control device for museum displays. The Maxi One S offers a unique scalable output: a single unit in remote location can reliably maintain stable humidity levels in multiple small, or one or more very large showcases, up to 80 meters distant. The Maxi One S can provide up to 430 cubic meters of pollution free, clean, humidity controlled air per day.One or more air pumps are used to provide filtered air at the delivery pressure and flow required for the application. In the Maxi One S the air is passed through an cooled water bath to control humidity levels, and distributed to the enclosures via flexible tubing.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

The PMCG humidity generator is a novel approach for controlling humidity in museum quality display cases. The PMCG units are based on solid state technology – unlike other units, they don’t require filling or emptying of reservoirs. Once the machine is setup, the humidity inside the display case is maintained for years without the necessity of checking the water level, adding water or any other regular maintenance. PMCG devices are able to maintain relative humidity from below 25% up to 60%, at ambient temperatures of below 0°C up to 40°C. The newest models are equipped with a WiFi connection to internet.

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

The Preservatech Mini One is a miniature humidity control device for museum showcases and storage enclosures. This robust and extremely efficient unit can reliably control humidity in individual or multiple enclosures. The Mini One active microclimate generator is a sixth generation system, satisfying the demanding standards of preventive conservation and modern museum design. It incorporates the most recent developments in electronic humidity control, noise suppression, and pollution abatement — built on the heritage of a family of microclimate control devices extending back to 1978. This positive pressure microclimate control system will typically maintain the relative humidity level in a sealed museum enclosure to within two percent (or less) of your target relative humidity. Depending upon the ambient temperature conditions and enclosure construction, relative humidity levels of less than thirty-five to over eighty percent can be attained.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The recording of operating data such as flow volumes, pumping pressure, operating hours and power consumption of the pumps etc. is essential for the state monitoring of – usually municipal – pumping stations and pressure line as well as for the diagnosis of machine components. Data recording system with LCD display for the electronic acquisition, display, recording, evaluation, remote transmission and archiving of up to 6 analogue and digital input signals. Product features For daily, monthly, annual evaluation; meter statuses, operating times and volumes; min., max. and mean value recording Multi-colour display, digital, bar chart and graph representation Archiving in the internal memory and on compact flash card (no data lost in the event of a power failure!) Remote data transmission via standardised interfaces Suitable for door installation in the AWAcontrol control cabinet

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ADS-TEC INDUSTRIAL IT GMBH

Germany

With the software-based Big-LinX Edge Client any machine can be securely controlled and maintained remotely via a Windows-based HMI. The HMI serves as a remote maintenance access point without the need for additional hardware.

Request for a quote

ADS-TEC INDUSTRIAL IT GMBH

Germany

Big-LinX is an IIoT service & maintenance platform for secure remote maintenance of machines and systems, as well as for Industry 4.0 and IIoT applications. Due to remote maintenance, expensive machine downtimes can be minimised or even prevented thanks to preventive and direct interventions. Prepare machine data graphically in dashboards via the cloud and set up alarms. The alarm function is used to inform previously defined employees about a possible malfunction. Big-LinX offers customers a secure investment in the future, as the portal grows with the customer's needs. Get your company ready for digitalisation.

Request for a quote

DANWELL APS

Denmark

Install an our meter model WDEK30 with impulse device; this impulse device has a electric wire long 3 meters, at the end of this wire you can link the our impulse counter (if you need more length for the wire, you can add a normal electric wire). Our WDEK30 can be equipped with the follow scale impulse: DN50-65-80-100:1 impulse for 100 liters DN125-150-200 1 impulse for 1000 liters

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

A turn-key condition monitoring solution combining the versatility of ultrasound, the analytics of vibration, standard communication protocols and an embedded trending and analysis software. Vigilant Configure Vigilant to any Critical Asset Vigilant is a flexible data collection pod. Input any combo of eight ultrasound and vibration sensors and receive continuous feedback from your assets. 4 channels for Temperature, Tach and Pressure create an all-in-one solution for critical and guarded assets. Vigilant Highlights: - 8 channels (Ultrasound or Vibration) - 4 channels (Temp/Tach/Process) - Embedded data management software - Trends/Spectrum/Waveform/Waterfall - Open communications protocol - Static and Dynamic data

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

CONMONSense delivers precise, repeatable data about the health of your assets and electrical systems also in the most challenging environment. Its resonant piezo element is optimized for ultrasound driven lubrication, mechanical fault detection, and monitoring the health of valves, steam, hydraulic systems and electrical defects. Ultrasound is a true measure of the FITness of your facility. Most assets produce FRICTION, IMPACTING, and TURBULENCE as defect indicators. CONMONSense hears these phenomena at their inception and delivers an analog signal response to your connected measurement system. With an output range from 4-20mA or from 0-10V, CONMONSense mounts permanently to any asset to provide continuous condition monitoring data. Avoid unplanned downtime and put the safety of your plant and colleagues first.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Why we Lubricate Bearings For 4000 years we have been lubricating our machinery and rotating assets to increase their efficiency, reliability and lifespan. Proper bearing lubrication minimizes the surface contact of machinery, reducing undesired friction, excessive heat, metal-on-metal contact and wear and tear. Lubrication not only protects ball and roller-element bearings from themselves by reducing friction but also from corrosion and the elements. Grease is the lubrication of choice within the industry, as it is easy to apply and it provides the bearing housing with a protective seal from the elements. For a procedure proven reliable for the past 4 millennia, it is surprising to hear so many premature bearing failures are lubrication-related. Improper lube selection, amount, intervals as well as lubricant contamination and degradation are to blame.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

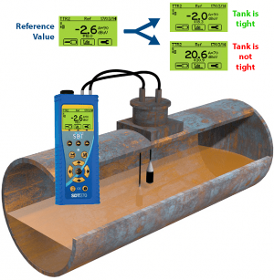

Peace of mind and reassurance for the operator Tightness Testing on Underground Storage Tanks and other Air Tight Compartments The ability to test for tightness with an ultrasound detector is extremely powerful and versatile. It is the only way to ensure that underground storage tanks are air tight. But that isn’t all that ultrasonic tightness testing can be used on. There are many things that need to be air tight. Like the engine or cabin of a car, large shipping containers or the bearing housing in a paper production plant. When somethings tightness integrity deteriorates one or two things can happen. Things can leak out, or things can get in. And whenever possible, it is advantageous to avoid either of these from happening. Fuel Leaking From Underground Storage Tanks Damage the Environment and Waste Valuable Resources Overtime the tightness integrity of underground storage tanks or other air tight compartments can deteriorate.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Valves play a crucial role in the transportation of gas, oil and water throughout your plant. They start and stop flow while also preventing backflow and regulating flow and pressure. They can be found in the hundreds and even thousands at large facilities. Steel, pulp, food and pharmaceutical as well as other industrial facilities installed on their pipes. When valves fail or leak it will result in the loss of energy, product quality and can also lead to potential downtime. Whether it’s internal or external leaks, or issues with flow regulation, valve leaks are a threat to your factory processes. A major component to a plants efficiency is valves operating properly. Ultrasonic inspection can quickly identify function and malfunctioning valves. So they can be tagged and repaired quickly to avoid, diminished production.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

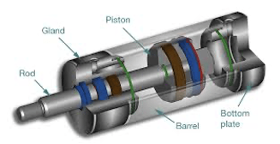

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Keep Your Steam Clean, Safe And Energy-Efficient Steam is an essential resource is many industrial processes. As a result most facilities have a vast network of piping, valves, flanges and steam traps. Within these systems there exists constant flow and turbulence. As pure steam travels from your boilers to their point of use, some cooling is inevitable. The result is accumulated condensate and gases. Steam traps purge this waste and keep your system pure. A fully-functional steam trap opens, closes or modulates automatically. It discharges condensate once formed, unless the heat from the condensate can be used. It is energy-efficient and does not waste quality steam. It removes impurities from the live steam, and maintains purity and efficiency throughout the system. Steam Trap Failure Causes Losses to Product Quality, Safety and Energy Loss Steam traps are necessary for the overall efficiency of heat energy transfer.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Safely Inspect Electrical Systems with Ultrasound Electrical failures pose a tremendous safety threat and have the ability to shut down operations entirely Industrial plants require a lot of power to operate, and much like the machinery required for production, their electrical systems can also fail. The Importance of Maintaining your Electrical Systems The implications of a total electrical system failure are far more severe than that of an ordinary mechanical failure. They have the potential to damage equipment, cut power flow and cause downtime for days, seriously injure or kill workers in the immediate vicinity and even impact the surrounding areas power grid. Faults in electrical systems can be detected at their earliest stages with regular ultrasound inspection and therefor prevented far before anything catastrophic happens.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. Compressed air is the most versatile and therefore widely used resource in industry. Using atmospheric pressure to transfer energy during industrial processes, compressed air can be found powering air tools like drills and hammers, hydraulic air cylinders for automation in manufacturing processes and much more. Compressed air is also used to power air brakes on mobile fleets and trains. Air Compressor Expenses It is so commonly found in industry it is often referred to as the fourth utility to electricity, water and gas. Of the four, compressed air consumes the most energy. Air compressor systems can differ very greatly in size, output and cost. What remains constant, is the initial investment in a compressor system is only 25% of the expenses associated with it, over its lifetime. The other 75% of the costs go to energy used to compress the air.

Request for a quoteResults for

Monitoring and control equipment - Import exportNumber of results

68 ProductsCountries

Company type