- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal technology

Results for

Metal technology - Import export

MINEBEA INTEC GMBH

Germany

The new Mitus metal detection system is an inspection solution with the highest precision in detecting foreign objects in all applications where this is required. Using flexible MiWave Modulation Technology, the system ignores fluctuating product effects due to product variations in shape, size and composition, minimising false rejections. Foreign objects are reliably detected. In addition, the metal detector scores with its variety of models, which enables easy integration into existing systems.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Checkweigher Flexus® Combi combines the benefits of checkweighing and metal detection technology in one space-saving system. Minimal space – maximum quality control. Hygienic design for easy cleaning and the highest level of quality in your production operations Safety and reliability thanks to EMFC load cell technology The ideal solution every time – for your application configure Flexus® Combi Easy to combine with metal detection technology Vistus® For process speeds of up to 1.5 m/s MID approved for up to 3 m/s

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Sheet metal deep drawn stamping are one of metal forming technology with high material usage and precision, welding is unnecessary on deep drawn stamping parts, its shape can be round, square, oval, etc, most of kitchware are made by deep drawn stamping, like cups, cooker, sanitery ware, bowl, etc, material will be stainless steel, aluminum, iron, copper.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Checkweigher Flexus® meets the strictest requirements when it comes to hygienic design guidelines for packaged foods. A wide range of configurations ensure that every requirement is covered. Hygienic design for easy cleaning and the highest level of quality in your production operations Safety and reliability thanks to EMFC load cell technology The ideal solution every time – configure Flexus® for your application Easy to combine with metal detection technology Vistus®

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

THE BENEFITS OF TWO WORLDS Series components made of metal with complex shapes are usually very time-consuming and expensive to put into production -- but luckily there is now a superior alternative for these kinds of demanding workpieces in the form of MIM technology from Zimmer Group! The MIM process allows us to manufacture metal parts of almost any shape using an injection molding process, as easily as though it were plastic! This process lets us elegantly combine the geometrical freedom of plastic injection molding with the outstanding rigidity and wear characteristics of metals. The result is a thoroughly impressive technology for manufacturing metallic series production components with complex shapes -- and at very attractive prices, too!

Request for a quote

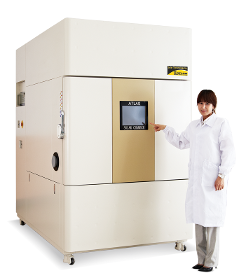

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEC 6100 is part of the Solar Technology by Atlas market approach offering integrated, ready-to-use test chambers for various solar and environmental applications. The SEC 6100 combines environmental simulation with metal halide lighting technology. It's a full function climatic chamber with additional simulation of the global sunlight spectra. Exposure volumes of 14m 3 are offered within the largest standard double door walk-in solar environmental chambers for e.g. multiple full PV modules testing. Test chamber capacity approx. 14,200L Radiation area approx. 48,000cm 2 Lamp: 6x MHG 4,000W Luminary Intensity: 800W ~ 1200W /m 2 (Adjustable) Wavelength: 280 ~ 3,000nm (Full Spectrum) -30℃ ~ +100 °C (W/O Radiation) -20℃ ~ +100 °C(W/ Radiation) 30% ~ 95%RH (W/O Radiation) 20% ~ 80%RH (W/ Radiation) 12.1" color touch screen Graphic User interface Intuitive control features and easy-to-use programming logic 6 Channel DAQ integrated for temperature sensors Multi-source temperature control pre-implemented and selectable in user interface Pre-wired for BST (Black Standard Temperature) sensor and control Pre-wired for plug-and-play radiometer for irradiance measurement Galvanized steel with powder coated exterior Engineered diffusive reflective stainless steel inner testing chamber for optimum spatial uniformity Easy access swing doors to luminary systems Robust refrigeration system for precision control of environmental parameters Multi-stage safety features Option Atlas25+ Core Cycles Indoor Filter Pyranometer CMP6 Class 1 - General Purpose Black Standard Temperature (BST) Controlling the Black Standard Temperature (BST)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEC 4100 is part of the Solar Technology by Atlas market approach offering integrated, ready-to-use test chambers for various solar and environmental applications. The SEC 4100 combines environmental simulation with metal halide lighting technology. It's a full function climatic chamber with additional simulation of the global sunlight spectra. Exposure volumes of 10500 liters are offered within the SEC 4100 standard double door walk-in solar environmental chambers for e.g. full PV modules testing. Test chamber capacity approx. 10,500L Radiation area approx. 32,000cm 2 Lamp: 4x MHG 4,000W Luminary Intensity: 800W ~ 1200W /m 2 (Adjustable) Wavelength: 280 ~ 3,000nm (Full Spectrum) -30℃ ~ +100 °C (W/O Radiation) -20℃ ~ +100 °C(W/ Radiation) 30% ~ 95%RH (W/O Radiation) 20% ~ 80%RH (W/ Radiation) 12.1" color touch screen Graphic User interface Intuitive control features and easy-to-use programming logic 6 Channel DAQ integrated for temperature sensors Multi-source temperature control pre-implemented and selectable in user interface Pre-wired for BST (Black Standard Temperature) sensor and control Pre-wired for plug-and-play radiometer for irradiance measurement Galvanized steel with powder coated exterior Engineered diffusive reflective stainless steel inner testing chamber for optimum spatial uniformity Easy access swing doors to luminary systems Robust refrigeration system for precision control of environmental parameters Multi-stage safety features Option Atlas25+ Core Cycles Indoor Filter Pyranometer CMP6 Class 1 - General Purpose Black Standard Temperature (BST) Option Controlling the Black Standard Temperature (BST)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEC 600 is part of the Solar Technology by Atlas market approach offering integrated, ready-to-use test chambers for various solar and environmental applications. The SEC 600 combines environmental simulation with metal halide lighting technology. It's a full function climatic chamber with additional simulation of the global sunlight spectra. Exposure volumes of 600 liters are offered within the SEC 600 standard single door solar environmental chambers for e.g. PV cell or mini modules testing. Test chamber capacity approx. 600L Radiation area approx. 3,000 cm 2 Lamp: 1x MHG 2,500W Luminary Intensity: 800W ~ 1200W /m 2 (Adjustable) Wavelength: 280 ~ 3,000nm (Full Spectrum) -40℃ ~ +120 °C (W/O Radiation) -20℃ ~ +120 °C(W/ Radiation) 30% ~ 95%RH (W/O Radiation) 20% ~ 80%RH (W/ Radiation) 12.1 " color touch screen Graphic User interface Intuitive control features and easy-to-use programming logic 6 Channel DAQ integrated for temperature sensors Multi-source temperature control pre-implemented and selectable in user interface Pre-wired for BST (Black Standard Temperature) sensor and control Pre-wired for plug-and-play radiometer for irradiance measurement Galvanized steel with powder coated exterior Engineered diffusive reflective stainless steel inner testing chamber for optimum spatial uniformity Easy access swing doors to luminary systems Robust refrigeration system for precision control of environmental parameters Multi-stage safety features Option Atlas25+ Core Cycles Indoor Filter Pyranometer CMP6 Class 1 Black Standard Temperature (BST) sensor Controlling the Black Standard Temperature (BST)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Degradation and Heat Sunlight can have adverse affects on materials and components, oftentimes initiating and accelerating the degradation process as it interacts with temperature, moisture and other environmental effects. In addition, it is critical to understand the effects of heat created by sunlight with respect to operational performance, thermal management, noise and dimensional stability. A new product should be tested under solar environmental conditions representative of those locations in which it will exist - anywhere ranging from the heat of the outback in Australia to the frigid climate of arctic areas. Atlas solar simulation systems are custom-designed in both power and size. Having this flexibility, they can be integrated into various types of environmental test chambers whether they be small or walk-in, chambers used in component/ small product testing or drive-in chambers for complete vehicle testing, even up to extra large systems for trains, trucks and aircrafts. Superior Solar Simulation with SolarConstant A key to the success of solar environmental testing is the quality of the solar simulation itself. A close spectral match to natural sunlight is critical for accurate reproduction of test conditions. The Atlas SolarConstant luminaire offers high irradiance efficiency and superior spatial uniformity on the test area. Combined with special Metal Halide Global (MHG) lamps and optical filters, the SolarConstant creates a spectral distribution that closely matches natural sunlight. Its proven modular design makes this unit ideal for large custom-designed solar simulators as well as smaller standardized laboratory test systems. SolarConstant Serving Global Testing Needs SolarConstant products are designed to meet a large number of standards as well as industry test methods such as DIN 75220, MIL-STD-810, IEC 61215, IEC 904-9, EPA 40-CFR/ SC03, BMW PR306.5, Renault 32-00-022, Telcordia GR-487-CORE and others. Atlas offers a complete series of SolarConstant luminaires to satisfy an array of global testing needs: SolarConstant MHG 4000/2500/1200/575: These luminaires utilize Metal Halide Global technology for full-spectrum solar simulation. Optical filters adjust the output for the best match to natural indoor/outdoor sunlight. They are ideal for solar simulators used to determine thermal heating effects of solar radiation such as fit and finish, dimensional stability or thermal transmission. They are also suited for identifying photodegradation effects of polymers and coatings such as cracking, color fading and other failures, or testing PV module performance. SolarConstant MIL: These luminaires utilize Metal Halide Global technology combined with a unique "multi-level" output for full-spectrum solar simulation. Especially useful for satisfying stringent MIL-STD-810G method 505.5 (Procedure I) - determination of heat produced by 24-hour cycles of solar radiation. It is also ideal for agro-science requiring diurnal cycles, e.g. plant growth studies and others. SolarConstant MH 1500/1200/1000: These luminaires utilize Metal Halide technology for specific high-UV level testing or to meet limited budget applications. Solar Constant UV 2000: These luminaires utilize Mercury technology for creating UV radiation (280 - 400 nm) and are used to study photo-aging effects caused by solar UV radiation only. In addition to the SolarConstant line of products, Atlas comolements its luminaire portfolio with Halogen technology for visible (VIS) and heat radiation (IR). IR-luminaires with 2000W / 1500 W are used to set up high-performance systems for testing heating effects similar to heating caused by sunligt. In addition to the SolarConstant line of products, Atlas comolements its luminaire portfolio with Halogen technology for visible (VIS) and heat radiation (IR). IR-luminaires with 2000W / 1500 W are used to set up high-performance systems for testing heating effects similar to heating caused by sunligt. From Outdoor Data to Laboratory Testing No environmental laboratory test is complete withut the confirmation and correlation to natural conditions. Atlas operates a number of outdoor exposure sites in key climate zones worldwide and can produce the natural exposure data you need. Using our expertise in both outdoor and accelerated testing, Atlas can assist you in reproducing outdoor conditions in your laboratory enabling your testing to reliable, fast and as realistic as possible. Test Chamber Examples Atlas has installed over 100 systems worldwide and is a leader in combining the technologies of testing with solar simulation. Below are examples of the most common test chambers with solar simulators: Climate test chamber with wind tunnel and solar simulator Climate test chamber with dynamometer and solar simulator Solar heat load test chamber with solar day cycling Climate test chamber with dynamic road simulation and solar simulator Custom solar simulator for PV module testing, Light Soak testing, I/V curve tracing Solar environmental Walk-in test chamber for component / product testing Atlas CESORA Atlas' CESORA (Calculation of Effective Solar radiation) software is extremely useful in the absence of measured outdoor data. With CESORA, you can calculate effective solar radiation for any time, day, month or year on any titled surface over any spectral range from 250-3000 nm. Positioning System To allow the SolarConstant solar simulator to move and replicate various natural solar conditions, a mechanical positioning system is typically installed. This enables motorized movement of the solar array within all desired spatial directions to simulate solar day cycles for example. Atlas offers both low-cost manual remote controls or full automatic alternatives that are integrated into the Atlas software. Positioning systems are typically customized towards the application and local test facility. Atlas will work with you to define the SolarConstant positioning system that will work best for you. Control System The operation of the SolarConstant system is handled by a dedicated operator interface. Atlas provides tailored menu-driven software for the programming and operation of each solar simulation system. Any solar simulation profile - for example morning, noon, afternoon, etc. can be stored and combined with various types of programmed test sequences for a complete integrated test program. For seamless operator interface, the Atlas designed solar control interface can be linked to the master IT environment of the test facility. We believe that a strong grasp of our customers' requirements is a key factor in developing a solution tailored to their needs. In order to simplify initial communications and understand your requirements more easily, please fill out the provided questionnaire under 'Downloads' and fax it back to +49-6105-9128-80.

ZEPTER INTERNATIONAL

Switzerland

The Zepter Masterpiece Cookware is a patented system enabling proper and everlasting preparation of healthy food, for a better and longer life. The combination of the Zepter system’s multifunctional elements enables proper preparation, cooking, frying, serving and preservation of healthy food. The Zepter Multisystem is manufactured in Milan, Italy, at one of Zepter’s seven factories in Europe, pursuing the highest quality and safety standards. Zepter’s unique combination of superior metal 316L, cutting-edge Zepter technology and magnificent Zepter design allows you to cook without adding water and to fry without adding fats, thus preserving the food’s nutrients. With the Zepter Multisystem, food is cooked in its own juice, sufficient to preserve its essential nutrients and organoleptic properties. The Zepter Masterpiece system for preparing healthy food is fast, easy and always healthy. Presentation QUALITY MATERIALS + HEALTHY COOKING

Request for a quote

TEPROSA GMBH

Germany

Baking varnish is a special joining technology for sheet metal packages. After the individual lamellas have been cut, electrical steel with a baking varnish coating is baked into a sheet metal package in a two-stage temperature step. The result is a full-surface, solid connection between the individual sheets with complete insulation. Sheet metal packages manufactured in this way have high precision and perfect magnetic properties. Advantages of the Backlack process: The Backlack process offers several advantages over alternative packaging processes, which we will discuss in detail below. Precision – Sheets coated with baking varnish are baked over the entire surface. This means that even delicate slats can be assembled precisely.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

In order to avoid chemical reactions such as curing or crystallization during the dosing process, any contact with metal in the area in contact with the material in the dispenser was avoided. The materials used have been carefully selected: On the one hand with regard to chemical resistance to adhesives and other fluids and on the other hand with regard to highest resistance to physical wear by abrasive media. Highly reactive materials such as sulfuric acid, anaerobic UV curing acrylates and electrolytes require special treatment. They can be dosed with highest accuracy and best repeatability. The new metal-free dispenser can be easily installed on existing ViscoTec drive technologies and offers the same advantages as other proven dispensers from the portfolio of the dosing technology specialist. The metal-free dispenser is available in many sizes.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Flap discs that excel in quality, performance, and handling are Tyrolit's standard. As a leading manufacturer of abrasives, Tyrolit offers a wide range of flap discs for various applications, including trimmable discs and those with natural fiber cores. Specifications vary for machining steel, stainless steel, or nonferrous metals, incorporating technologies like CERABOND, LONGLIFE, and FASTCUT. Each flap disc in our assortment is designed for specific uses. CERABOND discs, available with fiberglass or trimmable plastic backing, offer up to 30% more material removal and 100% utilization. FASTCUT discs are ideal for edge grinding and weld seam removal, providing maximum stock removal on various steels. Flap discs for nonferrous metals feature ceramic grain for self-cleaning and sharpening, preventing smearing and dullness. The C-TRIM with LONGLIFE technology ensures an above-average lifespan and full abrasive cloth utilization.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Available in many versions for use in cooling, heating, beverage machines, vending machines, household appliances, instrument technology, etc. In metal and plastic cases. With device socket, plug connection, wiring, encapsulated probes. With double NTC/PTC, with analogue signal output

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEC 1100 is part of the Solar Technology by Atlas market approach offering integrated, ready-to-use test chambers for various solar and environmental applications. The SEC 1100 combines environmental simulation with metal halide lighting technology. It's a full function climatic chamber with additional simulation of the global sunlight spectra. Exposure volumes of 1150 liters are offered within the SEC 1100 standard single door solar environmental chambers for e.g. PV cell or mini modules testing. Test chamber capacity approx. 1,100L Radiation area: approx. 5,600 cm 2 Lamp: 1x MHG 4000W Luminary Intensity: 800W ~ 1200W /m 2 (Adjustable) Wavelength: 280 ~ 3,000nm (Full Spectrum) -40℃ ~ +120 °C (W/O Radiation) -20℃ ~ +120 °C(W/ Radiation) 30% ~ 95%RH (W/O Radiation) 20% ~ 80%RH (W/ Radiation) 12.1" color touch screen Graphic User interface Intuitive control features and easy-to-use programming logic 6 Channel DAQ integrated for temperature sensors Multi-source temperature control pre-implemented and selectable in user interface Pre-wired for BST (Black Standard Temperature) sensor and control Pre-wired for plug-and-play radiometer for irradiance measurement Galvanized steel with powder coated exterior Engineered diffusive reflective stainless steel inner testing chamber for optimum spatial uniformity Easy access swing doors to luminary systems Robust refrigeration system for precision control of environmental parameters Multi-stage safety features Option Atlas25+ Core Cycles Indoor Filter Pyranometer CMP6 Class 1 - General Purpose Black Standard Temperature (BST) Controlling the Black Standard Temperature (BST)

NORELEM FRANCE

France

Ceramic bearings Si3N4. Bearing cage PTFE. For most applications Si3N4 is the preferred material for ceramic bearings. Silicon nitride bearings are light, very hard and highly wear resistant. High and ultrahigh performance bearings are used in e.g. aerospace technology, metal production industries (high application temperatures), machine manufacturing, chemical industries (chemically aggresive substances), pharmaceutical and medical industries, semiconductor and biotechnology (clean room enviroments which may not be contaminated by lubricants). On request Special version with PEEK ball cage. Without ball cage.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEC 2100 is part of the Solar Technology by Atlas market approach offering integrated, ready-to-use test chambers for various solar and environmental applications. The SEC 2100 combines environmental simulation with metal halide lighting technology. It's a full function climatic chamber with additional simulation of the global sunlight spectra. Exposure volumes of 4050 liters are offered within the SEC 2100 standard double door walk-in solar environmental chambers for e.g. full PV module testing. Test chamber capacity approx. 4000L Radiation area approx. 13,600 cm2 for Uniformity Class B Radiation area approx. 16,000 cm2 for Uniformity Class C Lamp: 2x MHG 4,000W Luminary Intensity: 800W ~ 1200W /m 2 (Adjustable) Wavelength: 280 ~ 3,000nm (Full Spectrum) -40℃ ~ +120 °C (W/O Radiation) -20℃ ~ +120 °C(W/ Radiation) 30% ~ 95%RH (W/O Radiation) 20% ~ 80%RH (W/ Radiation) 12.1" color touch screen Graphic User interface Intuitive control features and easy-to-use programming logic 6 Channel DAQ integrated for temperature sensors Multi-source temperature control pre-implemented and selectable in user interface Pre-wired for BST (Black Standard Temperature) sensor and control Pre-wired for plug-and-play radiometer for irradiance measurement Galvanized steel with powder coated exterior Engineered diffusive reflective stainless steel inner testing chamber for optimum spatial uniformity Easy access swing doors to luminary systems Robust refrigeration system for precision control of environmental parameters Multi-stage safety features Option Atlas25+ Core Cycles Indoor Filter Pyranometer CMP6 Class 1 - General Purpose Black Standard Temperature (BST) Controlling the Black Standard Temperature (BST)

Do you sell or make similar products?

Sign up to europages and have your products listed

VALDAMARK LIMITED

United Kingdom

Cortec VpCI® 418 L / VpCI® 418 LM Cleaner & Degreaser. Powerful cleaner/degreaser with built-in corrosion protection.Removes grease, oil, and grime from metal and non-metal surfaces. VpCI® technology forms a protective layer, preventing rust & corrosion.Water-based, biodegradable, and user-friendly.Ideal for industrial, commercial, and household use.Versatile applications include machinery, tools, vehicles, and more.Low odour, non-flammable, and safe. Available in liquid (418 L) and gel (418 LM) formulas.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec VpCI® 417 Heavy Duty Cleaner & Degreaser. Powerful, versatile cleaner removing grease, oil, dirt from metal & other surfaces.Includes VpCI® technology for instant & long-lasting corrosion protection. Biodegradable, water-based formula is safe for users & environment.Ideal for industrial, automotive, marine use.Easy to apply, dilute & use.Extends equipment life, saves costs.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec VpCI® 387 Acrylic (Water-Based) Hi-Build Topcoat. High-performance, water-based acrylic topcoat offering superior corrosion protection for ferrous & non-ferrous metals. Leveraging Cortec's patented VpCI technology, it creates a molecular barrier against corrosion.Features high-build formula for excellent coverage & durability, while being eco-friendly with low VOCs.Offers strong adhesion, flexibility, and multi-metal protection.Ideal for maintenance, shipping, storage, and various industrial applications. Easy to apply by brush, roller, or spray.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec Eco-Corr® Biodegradable VpCI® Film. Eco-friendly corrosion protection.Biodegradable film with VpCI® technology shields metals from rust.Ideal for various industries, including automotive, electronics, and aerospace.Offers multi-metal protection, leaving no harmful residue. Easy to use, cost-effective, and reduces environmental impact.Perfect for sustainable packaging and preservation.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec EcoWeave® is an eco-friendly, corrosion inhibiting fabric using VpCI® technology. It protects metals from rust and tarnish without harmful chemicals.Versatile for various applications, it's durable, long-lasting, and easy to use. EcoWeave® is recyclable and reduces environmental impact.Offering superior corrosion protection while aligning with sustainability, it's a cost-effective solution for businesses seeking eco-friendly packaging and preservation.

Request for a quote

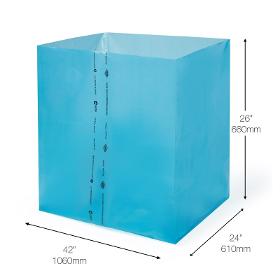

VALDAMARK LIMITED

United Kingdom

Cortec® VpCI®-126 Gusset Bags offer powerful corrosion protection for metals. Using VpCI® technology, these bags create a vapor that coats metal surfaces, shielding them from moisture, oxygen, and other corrosive elements. This versatile solution protects various metals, including steel, copper, aluminium, and more. The bags are reusable, durable, and non-toxic, making them ideal for various industries. With extensive testing and certifications, they provide reliable corrosion prevention for storage and shipping.

Request for a quote

VALDAMARK LIMITED

United Kingdom

X-O Wrap® Premium Metal-Guard® VCI Corrosion Protection Film is a top-tier packaging solution safeguarding metal components from corrosion during storage and transit. Engineered by Cortec®, a pioneer in corrosion control, this premium film offers unmatched protection against rust, tarnish, and oxidation.Its core, Metal-Guard® VCI technology, releases vaporous inhibitors forming a molecular shield on metal surfaces.Unlike traditional methods relying on desiccants or oils, X-O Wrap® provides contact-free protection, even in hard-to-reach areas. Crafted from durable, puncture-resistant polyethylene, the film is UV-stabilised for long-lasting performance.Versatile for various metals and applications, it's easy to use and environmentally friendly.By preventing costly corrosion, X-O Wrap® significantly reduces expenses.Combine it with Valdamark Direct's VCI products for a complete corrosion prevention system.Experience the future of corrosion protection with X-O Wrap®.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cotrec CorrLube™ VpCI Lithium EP Grease is a top-tier, multi-use lubricant providing unmatched corrosion protection and lubrication. Its lithium complex thickener and advanced Vapor phase Corrosion Inhibitor (VpCI) technology shield metal surfaces from rust, corrosion, and wear.VpCI molecules create a molecular barrier against moisture, salt, and corrosive agents, making it perfect for harsh conditions.Beyond corrosion prevention, this grease excels in lubrication. Its lithium complex thickener ensures strong adhesion and high viscosity, delivering reliable lubrication under heavy loads and extreme pressures.Enhanced by extreme pressure (EP) additives, it handles demanding applications with ease.Designed for versatility, it thrives from -40°F to 350°F, making it suitable for various climates.Ideal for bearings, gears, universal joints, chassis, farm, construction, automotive, industrial, marine, and HVAC equipment.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec VpCI® 170 Adhesive Foam Tape excels at corrosion protection and sealing. Unlike standard adhesive foam tapes, it incorporates Cortec's VpCI® technology, actively shielding metal surfaces from corrosion.VpCI® molecules vaporise, forming a protective layer on all metal, preventing corrosion without messy oils.This contrasts with basic foam tapes offering only passive protection through a physical barrier. Additionally, the tape boasts a high-performance adhesive for strong, long-lasting bonds to various surfaces, outperforming lower-quality alternatives prone to drying out.The closed-cell polyethylene foam is soft, conformable, and highly resistant to water, moisture, and air, surpassing open-cell foam options. Available in 1/8-inch and 1/4-inch thicknesses, it adapts to diverse needs.

Request for a quote

NITROXTEC ENDUSTRIYEL MAKINA BASINCLI HAVA VE GAZ COZUMLERI SANAYI TICARET LTD.STI.

Turkey

It enables you to reach bright, clean, burr-free and perfect cutting quality in laser cutting. Nitroxtec laser cutting system has been produced by paying attention to the thickness, type, cutting time and laser technology of the metal being cut.

Request for a quote

LLC ASL OYNA

Uzbekistan

Printing with UV paints opens up new design possibilities and allows you to apply full-color images on top of a fully painted bottle, thereby expanding the design possibilities. High image quality, maximum resolution and the ability to combine with other decoration technologies is the best way to distinguish your products from competitors. The use of UV ink with zero heavy metal content makes this technology as environmentally friendly and safe as possible.

Request for a quote

ITALGEAR SRL

Italy

Cylindrical ground gears are cut by hobbing machines of the latest generation and finished by Reischauer and Gleason CNC grinding machines equipped with automatic loaders and special software that allow the correction of the twisting errors that may occur in helical gear and, with special ground cycles strategy minimizing noise of gears in operation. ITALGEAR can also make the finishing of the gears after carburizing heat treatment adopting the Skiving technology, which allows the precise finishing of gears through superfinishing of the teeth with a hard metal PVD coated hobs. The technology allows production of groundquality precise gears while reducing cutting time and costs effective at the same time. On request, ITALGEAR engineers can team up with the Customer R&D and suggest any appropriate measures to optimize the gear meshing in order to obtain low noise in operation.

Request for a quoteResults for

Metal technology - Import exportNumber of results

78 ProductsCountries

Company type

Category

- Foundries - copper, bronze and brass (6)

- Plastic packaging (6)

- Copper and copper alloys (4)

- Printers - computer (4)

- Industrial sheet metal work (3)

- Lubricants, industrial (3)

- Metal powders (3)

- Condensers (2)

- Films for packaging (2)

- Food industry - machinery and equipment (2)

- Gold and silversmith's machinery and equipment (2)

- Passive electronic components and printed circuits (2)

- Weighing and dosing equipment (2)

- Air compressors - Tools and accessories (1)

- Bearings - ball, needle and roller (1)

- Brazing - equipment and supplies (1)

- Cylinders, hydraulic (1)

- Dosing pumps (1)

- Electronic components (1)

- Embossing machine tools (1)