- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal punching

Results for

Metal punching - Import export

MICRON AMERICA

Turkey

It has been designed and constructed with respect to the pre punch holes to prepare a connecting element assembly, especially for metal plates. These packages are produced in order to order and delivery for approximately 3 4 weeks.

Request for a quote

ADMET SP. Z O. O.

Poland

We offer sheet metal punching for all kinds of materials. We work on AMADA machines. Max width: 3000mm Max thickness: 6mm

Request for a quote

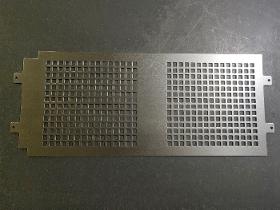

FOXLASER

Bulgaria

The punching is a preferred technology in cutting-out of galvanized metal sheets. In FoxLaser we have 4 pc. punching machines that enable us to process without repositioning sheet material with dimensions 3000/1500/3mm. The main advantage compared to laser technology is the possibility of cutting and forming of the sheet material. The combination usage of punching and laser cutting allows us to make numerous identical holes (grid) or just forming in a laser cut parts. The biggest advantage in FoxLaser punching are a tripple tooling we have that allows us to produce same time same part in all machines. For achieving maximum performance we work with wide range of functionalities by the well proved softwares SigmaNEST and Metalix CNCKad, in combination with the customized software of the company AMADA.

Request for a quote

DONLOUCO IRELAND LTD

Ireland

Donlouco Ireland Ltd has a proven track record for quality and sustainable supply of precision stamped parts to customers in Ireland, UK & Europe. Precision stamped parts. Precision punch tools-high tolerance. Fine blanking parts. Fine blanking & formed parts.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

HTMACH Turret Punch Press Machine is capable of working large sheet metals with fast axes speed and stroke frequency. It is used high level mechanic and electronic automation equipments in its construction. Machine keeps its compact structure with all its specialties and equipment. All of the components on the machine are world wide known brand names. Capacity is 1225mmX30ton

METAL IN LTD

Bulgaria

Metal In Ltd have two punching machines – TRUMPH and Raskin and two CNC bending machines TRUMPH. This allow us to produce punching details with maximum sizes 1250x2500 mm and maximum thickness 4 mm. Machines are with maximum length 3000 mm and power 120 tones. We also have eccentric presss machines with maximum power of kick 160 tones and hydraulic presses with maximum power 100 tones. We have our own production of punching and bending instruments. The company have three roller bending machines for sheet iron, profiles and tubes. Except upper mentioned operations we also make MIG-MAG and WIG welding, cleaning and powder coating.

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

Mercury steels are a set of steels that are hardened with water suitable for the construction of tools such as twist and dental drills, Guides, Drift punches, Countersinks , Center drills, Rasps, Hole punches, Metal saws, Drawing punches and all sorts of staples, connecting tab and similar tools.

Request for a quote

ANKARA BRONZ

Turkey

Mercury steels are a set of steels that are hardened with water suitable for the construction of tools such as twist and dental drills, Guides, Drift punches, Countersinks , Center drills, Rasps, Hole punches, Metal saws, Drawing punches and all sorts of staples, connecting tab and similar tools.

Request for a quote

KW HYDRAULIK GMBH

Germany

Punching Tools for Sheat Metall

Request for a quote

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 661012 Elastic cord Specification Elastic cord Braided elastic, with stitched-on belt and punched-in metal eye at both ends Model type: C (Customised) Dimension: approx. 60.0 mm wide Material: Polyester Colour: black Property: elastic Elastic Material: Natural rubber Packaging: loose in cardboard box

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched-plates,deep drawn parts for different industries.We providing relavent processes such as punch cutting,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Fine blanking is a special processing of precision sheet metal stamping. Including powerful blanking precision blanking, opposing die blanking and flat blanking precision blanking. The geometric shape, dimensional tolerance, shape tolerance and shear surface quality of fine-blanking parts are much higher than those of ordinary blanking parts. Fine-blanking technology plays a very important role in the field of automobile parts manufacturing. There is an essential difference between the process characteristics of fine blanking and ordinary blanking. Normal blanking controls the tearing of the sheet during the blanking process, while fine blanking tries its best to suppress the tearing of the sheet during the blanking. The fine blanking is always kept as one body before the parts are separated from the sheet material, and the metal sheet is always in the plastic deformation process during the fine blanking process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NINGBO FRIMA INDUSTRY CO. LTD.

China

The metal stamping service can be customized during the whole manufacturing process from the mold developing, designing to producing. Every demand from customers like metal stamping, punching, deep pumping and specific angle bending are measured and tested according to the measurement of metal materials then apply to each kind of metal. Features of our products: 1. Material: Steel, Stainless steel, Aluminum sheet, Copper etc. 2. Surface treatment: Zinc plated, Powder coating, Paint, Nickel plated etc. 3. Requirement: based on drawing and quantity. 4. Stamping equipment: 10-500T 5. Packing: we will offer you the standard package which includes plastic film, foam, carton and wooden box which is suitable for transporting 6. Delivery time: Within 20 days after receiving your 30% deposit

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom brass stamping parts We are professional custom brass stamping parts China manufacturer from Ningbo, All stamping parts can be custom made in our factory 10 Advantages you would get from FRIMA Stamping parts Precision OEM punching bending metal stamping parts (https//www.frimaparts.com/sheetmetalstampingparts/) Materials carbon steel, stainless steel, aluminum, brass

Request for a quote

GABELLA MACCHINE SPA

Italy

Cut-to-length lines for T-shaped panels Slitting and recoiling lines with automatic separators positioning Dedicated plants for pre-painted,? film-coated or other special materials (stucco-design, mesh, ground surfaces…) Special lines for panels production, with punching, shearing, roll-forming and bending Continuous punching lines Spool recoiling lines De-burring lines Combined lines with partial cut, where a part of the strip is recoiled for future use Machines for mass production or very flexible plants for small productions Cut-to-length and recoiling lines, with coils packaging stations. Customized and very enhanced productions, which integrate the sheet-metal processing with rotating turret punching (possibility of up to 24 different tools? a time, even in “multitools” solutions) or fiber laser cut.

Request for a quote

EQUILAB

Spain

The great versatility of the new MultiEQP-100 makes of this unit an essencial instrument to treat and make metallic samples. Effective to cut, crush and punch metallic samples, it can also prepare press pellets to be analyzed by XRF. The objective of punching the samples is to obtain pins for their ulterior analysis in Elemental Analizers. The objective of the crushing is to achieve flat surfaces wide enough to undertake spark analysis. The touch-screen and the intuitive software enable the user to control easily the ample variety of operations the MultiEQP-100 features. The two magnetic sensors included in the left hand side of the working units allow the automation of all the working cycles.

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD extrusion embossing allows for direct screwing in sheet metal and does away with press-fitted or welded nuts. The embossed structure formed in the process increases the number of turns for the screw and thus enhances its grip. In addition, extrusion embossing allows for higher torques than would be possible with simple screwing of multiple sheets. The technique is suitable for use in virtually all industries where sheet metal is machined and joined - stationary, robot-controlled or as a punch press system. This offer includes: Servo motor-driven extrusion embossing system • Embossing punching frame, horiz. throat 150 mm stationary or robot-guided • Servo motor-driven Press force approx. 58 kN Working stroke approx. 100 mm • Tool holder • Control cabinet incl. software ECKOLD VISU Embossing inserts are not included in the scope of delivery. Scrap suction/micro spray system on request. Contact us for a customised offer!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

LVD

Belgium

The VX-Series is the choice for production applications demanding high productivity. These full-featured sheet metal punching machines are exceptionally versatile – high hit rates, large feed clearance and powerful control capabilities combine to enable optimal throughput. Full sheet utilization and heavy sheet carrying capacity also add capacity – as do smart features and automation options. It all adds up to punching productivity that is unsurpassed. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy Reduction System minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software ABS automatic tool lubrication

Request for a quote

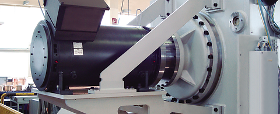

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

ANDRITZ KAISER GMBH

Germany

Maintenance is the key to lasting profitability. ANDRITZ provides a worldwide service network to ensure optimum availability of the customer’s plant. ANDRITZ machines will serve you faithfully for many decades if they are taken care of properly. We offer you the services of our maintenance personnel to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's availability, optimum production, and longer useful life. All services are provided from the ANDRITZ Kaiser site in Bretten: Repair work Spare parts Inspections Maintenance Environmental compatibility testing Rebuilds and modernization Training

Request for a quote

ANDRITZ KAISER GMBH

Germany

Maintenance is the key to long-term profitability. We provide a worldwide service to ensure optimum availability of the customer’s plant. Our machines are built for life and will serve you faithfully for many decades if they are taken care of properly. ANDRITZ Kaiser offers you service and maintenance in order to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's availability, optimum production, and longer useful life. All services are provided from our site in Bretten (repair work and spare parts, inspections, maintenance and environmental compatibility testing, as well as rebuilds and modernization, including training). Our machines are built for life and will serve you faithfully for many decades if they are taken care of properly. ANDRITZ Kaiser offers you service and maintenance in order to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's...

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

Creating an optimal bond between a metal plate and the silicone: that was the challenge Enbi Plastics was given by Océ Technologies, a major player in printing and copying equipment. They needed a new wiper assy; a part on the print head that prevents streaks on the paper. Because this part needs to be somewhat flexible, silicone needed to be added to a small, punched metal plate, to which screw thread is welded. This construction did not allow for a mechanical bond between the metal and silicone, which meant chemical bonding was the only option. Together with the client, the mould supplier, the silicone supplier and others, we did extensive research into the best way to achieve this bond. It showed that preparing the small metal plates was the key. After several tests, we discovered the optimal way to do this. A number of factors play a role: from how to clean and sand the plate to humidity, temperature and the time in between the steps of the process. Every detail counts!

Request for a quoteResults for

Metal punching - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Punching machine tools (5)

- Grids, gratings and wire mesh (3)

- Industrial sheet metal work (2)

- SMALL METAL PARTS (2)

- Sheet metals - stamping (2)

- Cutting - steels and metals (1)

- Aluminium and aluminium alloys (1)

- Bending - steels and metals (1)

- Embossing machine tools (1)

- Grinding - steels and metals (1)

- Handling - Machines & Equipment (1)

- Laboratory equipment and instruments (1)

- Laser - cutting and welding machines (1)

- Metal structural work (1)

- Metals - Machines & Equipment (1)

- Perforation of steels and metals (1)

- Stamping - steels and metals (1)

- Steel & Metals (1)

- Steels and metals - machining (1)

- Tools & Hardware (1)