- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal punching

Results for

Metal punching - Import export

KW HYDRAULIK GMBH

Germany

Punching Tools for Sheat Metall

Request for a quote

JUMBO-TEXTIL GMBH & CO. KG

Germany

Item No.: 661012 Elastic cord Specification Elastic cord Braided elastic, with stitched-on belt and punched-in metal eye at both ends Model type: C (Customised) Dimension: approx. 60.0 mm wide Material: Polyester Colour: black Property: elastic Elastic Material: Natural rubber Packaging: loose in cardboard box

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ECKOLD TECHNICS GMBH & CO. KG

Germany

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

ANDRITZ KAISER GMBH

Germany

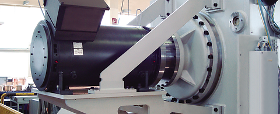

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

ANDRITZ KAISER GMBH

Germany

Maintenance is the key to long-term profitability. We provide a worldwide service to ensure optimum availability of the customer’s plant. Our machines are built for life and will serve you faithfully for many decades if they are taken care of properly. ANDRITZ Kaiser offers you service and maintenance in order to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's availability, optimum production, and longer useful life. All services are provided from our site in Bretten (repair work and spare parts, inspections, maintenance and environmental compatibility testing, as well as rebuilds and modernization, including training). Our machines are built for life and will serve you faithfully for many decades if they are taken care of properly. ANDRITZ Kaiser offers you service and maintenance in order to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's...

Request for a quote

ANDRITZ KAISER GMBH

Germany

Maintenance is the key to lasting profitability. ANDRITZ provides a worldwide service network to ensure optimum availability of the customer’s plant. ANDRITZ machines will serve you faithfully for many decades if they are taken care of properly. We offer you the services of our maintenance personnel to ensure optimum availability of your punching and metal forming production lines. Our know-how secures your plant's availability, optimum production, and longer useful life. All services are provided from the ANDRITZ Kaiser site in Bretten: Repair work Spare parts Inspections Maintenance Environmental compatibility testing Rebuilds and modernization Training

Request for a quote

LICHTGITTER GMBH

Germany

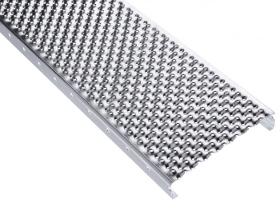

The perforated metal planks, type BN-G “Noppe, geschlossen”, the punched nobs pressed upwards are closed and offer high slip resistance. BN-G gratings are often used in indoor environments and there, where, on the one hand, a closed surface is desired and on the other, good accessibility must be ensured.

Request for a quote

LICHTGITTER GMBH

Germany

With perforated metal planks, type BN-O “Noppe, offen“ the bothsided punched holes have a diameter 8 mm and allows an excellent standing stability. Furthermore the drain holes exhibit good drainage. The BN-O grating guarantees a high stability for normal pedestrian traffic.

Request for a quote

LICHTGITTER GMBH

Germany

The perforated metal plank type BN-OP5 “Noppe, offen plus, 5mm“ was especially developed for pedestrian areas with „High Heel Proof“ requirements. The bothsided punched holes have a diameter of 5mm. The punching sequence corresponds to BN-OP7. This type of planking offers high slip resistance and also allows ladies in stiletto heels to walk safely on the gratings. Due to the small hole configuration it is difficult to see through from underneath, which is important in public access areas. The perforated metal plank type BN-OP8, corresponds to type BN-OP5 in terms of the punching pattern, but have twice the number of holes. The drain holes have a diameter of 8 mm and thereby increase the drainage performance and light and air permeability..

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

AMZ stands for automated material loading. AMZ enables automated loading of metal bars into our punching machines. Different materials types (thickness/width) can be processed successively. This only requires a short manual intervention when changing the type of metal bars, which allows for an ideal preparation of the production process. As soon as the machine has been started, the operator no longer needs to deal with feeding in the material, and can sort and further process the production parts during this time. The AMZ can also be seen as a small intermediate storage facility.

Request for a quoteResults for

Metal punching - Import exportNumber of results

14 ProductsCountries

Company type