- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- marble cutting machines

Results for

Marble cutting machines - Import export

DEWINCH CRANE SYSTEMS

Turkey

Gantry Crane -overhead Crane-Shaft Crane -Transfer Cart We are Manufacturer in TURKEY. www.dewinch.com.tr Whatsapp:+905444043600 export@dewinch.com.tr (New Product)

Request for a quote

DEMMAK DEMIRELLER MAKINA SANAYI VE TIC:A.S.

Turkey

Technical Data Disc Diameter : 350 mm Number of Disc : 5 pcs Disc Motor Power : 7,5 kW Number of Waste Conveyor : 2 pcs Max Cutting Stone Dimensions : 1000 x 1400 x 50 mm Cutting Thickness : 50 mm Total Electric Power : 68 kW Overall Dimensions : 2650 x 17500 x 2050 mm Operating System : PLC Control

Request for a quote

DEMMAK DEMIRELLER MAKINA SANAYI VE TIC:A.S.

Turkey

Technical Data Vertical Disc Motor Power : 110 kW Horizontal Disc Motor Power : 15 kW Bridge Motor Power : 1,5 kW Vertical Disc Diameter : 1000-1800 mm Horizontal Disc Diameter : 450 mm Hydraulic Unit Motor Power : 1,5 kW Total Electric Power : 136 kW Max Block Dimensions (weight x length x height) : 2000 x 3300 x 2400 mm Machine Dimensions : 5200 x 7700 x 4700 mm

Request for a quote

DEMMAK DEMIRELLER MAKINA SANAYI VE TIC:A.S.

Turkey

Technical Data Table Dimensions : 3500 x 1820 mm Max Disc Diameter : 800 mm Main Motor Power : 22 kW Overall Machine Dimensions : 784 x 620 x 330 cm Disc Vertical Movement Stroke : 400 mm Total Weight : 8500 kg

Request for a quote

DEMMAK DEMIRELLER MAKINA SANAYI VE TIC:A.S.

Turkey

Technical Data Max Block Dimensions : 1900 x 3200 x 2050 mm Strokes Per Minute : 92 rpm Stroke Length : 600 mm Main Motor Power : 90 kW Total Weight : 37500 kg Hydraulic Tensioning Units : 10 tons

Request for a quote

DEMMAK DEMIRELLER MAKINA SANAYI VE TIC:A.S.

Turkey

Technical Data Max Block Dimensions : 2000 x 3300 x 2050 mm Main Motor Power : 110 kW Overall Machine Dimensions : 480 x 1410 x 500 cm Useful Cutting Stroke : 800 mm Total Weight : 57000 kg Strokes Per Minute : 92 rpm Hydraulic Tensioning Units : 12 tons

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

STRIP SIZING MACHINE CAN BE 2 TO 8 HEADS. BELT WIDTH 70 CM. IT IS FULL AUTOMATIC WITH ALL SERVO MOTOR.

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

MAX STONE WIDTH : 20 CM MAX STONE LENGTH: 50 CM MAX STONE THICKNESS: 20 CM MAX BELT SPEED: 40 MT/M AVARAGE PRODUCTION CAPACITY: 15-18 SQM PER HOUR

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

Disc Diameter : Ø 300 - 400 Size Calibration System : Servo (Ball Screw + Linear Guides) Max. Cutting Thickness : 50 mm Min. Cutting Width : 200 mm Max. Belt Width : 1200 mm Control Panel : PLC + SCREEN Automatic Water Valves : Available Conveyor Belt Speed : 0-8 mt/dk Line Length ≌ 10000 mm

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

Number Of Machine Heads : Variable Number Of Calibration Heads : 1-4 Calibration Disk Diameter : Ø700 Number Of Moving Polishing Heads : 4-12 Moving Polishing Disk Diameter : Ø550 Number Of Moving Polishing Disk Abrasives : 9 Max. Stone Width / Thickness : 650x100 mm Conveyor Belt Speed : 0-4 m/min Max. Belt Width : 800 mm Control System : PLC

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

You can cut İrregular shape of stones

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

MAX STONE WIDTH : 12 CM MAX STONE LENGTH: 40 CM MAX STONE THICKNESS: 8 CM MAX BELT SPEED: 40 MT/M AVARAGE PRODUCTION CAPACITY: 14-17 SQM PER HOUR

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

WE USE FULL CASTING BODY SO YOU WILL HAVE VERY STRONG AND PRCISE CUTTING FOR MOSAIC WITH NO VIBRATION.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 700-1000 TPH dolomite crushing screening plant shall be a high-capacity industrial plant built to crush dolomite ore, which can produce all the required aggregates for construction projects. The term "TPH" means how many tonnes of dolomite ore the plant can get through in an hour, which is between 700 to 1000 tonnes per hour. This capability makes it be a core element in vast construction projects that require dolomite aggregates continuously. Dolomite, being of the composition calcium magnesium carbonate, is an essential material for construction, more so in the manufacture of concrete aggregates, road base materials, and other important building resources. These plants thus ensure that dolomite is well processed and sorted out to suit the specifications of construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

100-150 tph Granite Crushing and Screening Plants are specialized facilities designed to process granite stone into various sizes of aggregates at a throughput capacity ranging from 100 to 150 tons per hour. These plants consist of primary crushers, secondary crushers, vibrating screens, conveyors, and feeders specifically engineered for efficient granite processing. The primary crushers within these plants break down large granite stones into smaller fragments, which are further refined by secondary crushers to achieve the desired aggregate sizes. Subsequently, the crushed granite material undergoes screening using vibrating screens to separate it into different fractions based on size. By systematically crushing and screening granite stones, these plants produce high-quality aggregates suitable for a broad range of applications in construction, infrastructure development, road construction, and landscaping projects.

Request for a quote

BIZERBA SE & CO. KG

Germany

Fully automatic slicer with integrated weighing technology for portioning and weighing of individual slices. With fully automatic product fixation. Easy to service and very robust – perfect for industrial use. Area of Use Robust slicer for industrial production

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

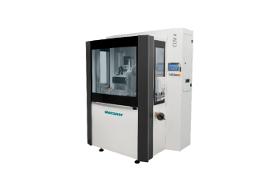

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

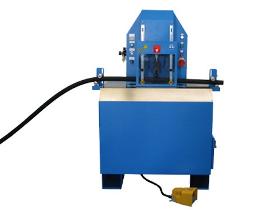

UNIFLEX-HYDRAULIK GMBH

Germany

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 1 ¼”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The safe high-quality cutting machine for the production process. All cutting blades are made of carefully tested material which ensures optimum cutting quality. 7.5 kW drive max. For hydraulic hose assemblies up to 3” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Planetary cutting machine for corrugated metal and PTFE hoses. Cutting results that often eliminate an additional step. This completely unique planetary cutting machine delivers almost scrap-free production and high efficiency. With a completely variable centering clamp system, all hose OD to the maximum rating for the machine can be cut. Approximate cutting time is 25 seconds for 1 ¼“ (ø DN 32). Productive and ergonomic •No dramatic flaring of the stainless steel braid •Reduces or eliminates time-consuming manual preparatory work thereby increasing productivity and lowering costs •Centering hose clamp system •Shortest cut possible from 10 cm •Minimizes personnel costs and preparatory work •No wrapping/unwrapping with adhesive tape required •Clearly laid-out user friendly software on a panel with a 6“ color display screen •Large article memory promotes productivity •Reference run for optimal positioning of the cutting blade for cutting all hose diameters CE compliant

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The small, light-weight cutting machine for workshops. 1-phase drive, 1.2 kW. For hydraulic hoses up to 1”. Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 2”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The new 2" 4SH + SAE R 15 hose cutting machine for workshops (also as a 3" industrial machine available). Designed to perfection. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Where pneumatic tools of the MBS series reach their performance limits, the eccentric cutting machine opens up new possibilities in cutting performance. Instead of a pneumatic cutting tool, the Metzner ST 25 uses an electrically driven eccentric mechanism that carries a punching blade. This enables us to increase the performance of the die-cut into completely new dimensions, of up to 800 cuts per minute. An agreeable side-effect: With the electric drive for the cutting tool, the ST 25 works very quietly – which is why customers with low-noise working environments also like to opt for this model.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The special feature of the Metzner CCM 4: the circular cutting machine handles both wet and dry cutting. Depending on the type of cut, the CCM 4 is equipped with a water-cooling lubrication system or micro-knife moistening and preparation for suction. The standard model comes with an integrated discharge conveyor (800 mm length); application range both in-line and off-line. For tubes with suitable material properties the CCM 4 Gasket offers the possibility to cut flat gaskets with the circular knife. Suitable for tubes with max. 30 or 50 mm diameter and a tube length of 1 mm to 1000 m.

Request for a quoteResults for

Marble cutting machines - Import exportNumber of results

46 ProductsCompany type

Category