- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machinery robotics

Results for

Industrial machinery robotics - Import export

AUTOMATED PRODUCTION LTD

United Kingdom

For nearly 30 years, APL has specialised in the design and integration of custom robotic & automation systems that have the ability to singulate and manipulate a diverse range of components including plumbing fittings, plastic mouldings and confectionery. The systems have been developed to automate components from bulk, inspect manipulate and place into the down stream equipment. Machine loading, batch sorting and quality inspection are common examples of the systems capabilities. Our tailor-made robotic systems are designed and built to provide cost effective solutions for our customers.

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

SAMSYS GMBH

Germany

Smart cable routing Compact and flexible installation Easy programming Multipurpose usage Software Built-In PLC

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. Industrial robots are the optimal solution for complex movements or systems with highest flexibility. We integrate and program the appropriate robot such as the Kuka robot and other brands.

Request for a quote

SAMSYS GMBH

Germany

The EasyPalletizer from EasyRobotics is a stationary palletizing robot for loading pallets with cardboard boxes or workpieces. The system is positioned on a conveyor belt. Then the robot picks up the cardboard box or the workpiece with a gripper. Depending on the proramization, it then sets it down on the pallet according to the customer’s requirements. The integrated ER+ software facilitates the programming of the sequence. Structure In combination with the Universal Robots robot UR10e the palletizer is available in different versions: On the one hand, the EasyPalettizer can be equipped with a base with lift. This makes it possible to move a stroke of 265 mm with the robot. Crates and workpieces can be stacked even higher on the pallet. Furthermore, it is possible to install a fixed base. This limits the standard height of the robot to 855 mm. In addition, the base can also be completely dismantled. This is useful if the palletisation will not reach great heights.

Request for a quote

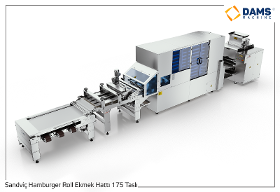

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional)

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program (Optional) CUTTING SECTION Machine body is 304 crom. The contact surfaces of the dough are 304 crom and crom coating.

Request for a quote

DAMS MACHINE

Turkey

Dough balls which are prepared according to the diameter of the desired product are released one by one into the hopper of the machine. The dough is crushed between two homogeneously heated plates with the hot pressing techniques. When the plates are spacing the rolled dough slides out of the machine. When the plates are spaced, the new dough roll falls between the plates from the hopper. Temperature of each plate; It is controlled by measuring separately. Product thickness can be adjusted manually.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text. In case of malfunction, remote access can be performed with PLC program.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

Machined parts or 3D additive manufacturing. Adaptable to production lines in the perfumery and cosmetics sector, packaging lines, dispensers and filling. We have a variety of materials and colors, we work with antistatic materials suitable for the sector, we have extensive experience in packaging, as well as special parts for your bottling machinery, maintenance solutions, stands for trade shows, spare parts, etc.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR5e is a lightweight industrial collaborative robot built for medium-duty applications (up to 5 kg). This general purpose robot was built with versatility and adaptability in mind. The UR5e is designed for seamless integration into a wide range of applications. Built with the future in mind, the UR5e is designed to grow in capability alongside your business, a spring board to improved product quality and productivity, so you will always be able to stay ahead of competition. Equipped with intuitive programming, versatile use and an almost endless list of opportunities for add-ons, the UR5e is able to complement production regardless of your industry, company size or product nature. The UR5e strikes the perfect balance between size and power.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR16e delivers an impressive 16kg (35.3 lbs.) of payload within a small footprint, and is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for heavier end of arm tooling and multi-part handling, and is especially useful for achieving shorter cycle times. The UR16e collaborative industrial robot is easy to program, offers fast set-up, is collaborative and safe, and like our other collaborative robots, offers one of the fastest payback times in the industry.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR3e is an ultra-lightweight, compact collaborative industrial robot, ideal for table-top applications. Its small footprint makes it ideal to be built directly inside machinery or in other tight workspaces. This cobot weighs only 24.3 lbs (11 kg), but has a payload of 6.6 lbs (3 kg). Its ±360-degree rotation on all wrist joints, and infinite rotation on the end joint, makes it well-suited for light assembly and screwdriving applications.

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR10e is an extremely versatile collaborative industrial robot arm with its high payload (10kg) and long reach capability. Its 1300mm reach spans wide workspaces without compromising precision or payload performance. UR10e addresses a wide range of applications in machine tending, palletizing, and packaging. The UR10e collaborative industrial robot is easy to program, offers fast set-up, is collaborative and safe, and like our other collaborative robots, offers one of the fastest payback times in the industry.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The three axis of motion enable a high performance and an efficient design of the robot system. The central pick up table picks up a whole layer of glass from the pallet. The table pushes the layer on the discharge table in one operation which seperates the glasses and transfers them to the production line. Since the roTeg depalletizing robot DERO II works with clamping jaws, numerous package sizes can be processed without mechanical devices. In each depalletizing cycle the interlayers are also picked up by the glass layer and collected in a magazine. The movability of the robot construction on the x axis enables the handling of different production lines. While one discharge table is still filled with glasses and being emtied line by line the DERO II already takes the next layer and serves the second discharge table.

Request for a quote

JSC IC SPA ANDROID TECHNICS

Russia

Collaborative robotic complex (CR) with carrying capacity of 5 kg is designed for automating cyclic production technological processes performed in a human-robot collaboration. Features: - Application of own driving decision developed by JSC “IC SPA “Android Technics”; - High level of positioning accuracy and repeatability due to the special algorithms of the control system; - Visually clear and user-friendly control interface; - Easy mounting, programing and resetting for new tasks performance. Content of additional software: - ETS (annual updating and maintenance); - Subject specialization; - Ready decisions regarding integration of CR in digital production. Warranty period: 12 months.

Request for a quote

JSC IC SPA ANDROID TECHNICS

Russia

Axial brushless electric motor AX Drive. Features: 1 High specific capacity and torque values. 2 Possible frameless use. 3 Possible control of rotation speed in a wide range. 4 Low weight, which does not significantly increase the spring weight. High torque values allow using this electric motor as a gearless drive, what significantly reduces capacity losses, weight, complexity and further maintenance ratio. Warranty period: 12 months.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

Sanding and polishing are two of the most skilful surface treatment processes. By robotizing these surface treatments, which are frequently used in many sectors, we increase the quality of the staff's working environment, increase productivity, reduce your need for consumables, and achieve the highest quality surface you need for every product you produce.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

We increase production speed by eliminating waiting times that reduce productivity in machine loading and unloading processes that do not require a high level of expertise. In addition we eliminate HSSE risks such as press feeding.

Request for a quoteResults for

Industrial machinery robotics - Import exportNumber of results

60 ProductsCompany type

Category

- Food industry packaging machinery (28)

- Industrial robots (14)

- Bakery and confectionery industry - machinery and equipment (11)

- Robotics (9)

- Assembly robots (5)

- Food industry - machinery and equipment (3)

- Automation - systems and equipment (2)

- Confectionery - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Cosmetics industry - machinery and equipment (1)

- Electric motors - dC (1)

- Rolling mills - machinery and installations (1)

- Software, technical and scientific (1)