- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial convection ovens

Results for

Industrial convection ovens - Import export

BTF

Belgium

Industrial furnaces BTF sa is the ideal partner for your thermal processes and custom solutions, in production or research!! BTF specialises in the design and construction of various types of industrial ovens and furnaces which are aimed at all industrial sectors and research laboratories. The range of operating temperatures of the units manufactured is up to 1,800°C. They can be designed to operate under air, under neutral gases, under vacuum or for performing special thermal treatments such as cimentation, (carbo) nitriding, …

Request for a quote

MAKSAN INDUSTRIAL KITCHEN EQUIPMENTS

Turkey

GENERAL FEATURES -Stainless steel chassis construction -Control unit with digital display -Highly efficient electric heating system -Double-glazed removable door system allows cleaning by the user -Perfect cooking with clockwise-anticlockwise fan system -Type of GN 1/1 tray kit allows cooking with gastronomy trays -Cooking cycle start at door closing -Safety thermostat provides safety -Interior design provides ease of cleaning -Lightning system provides clear visibility for foods -Water connection allows cooking foods with humidity -The flue outlet is controllable -User-friendly command interface -Motors and fans system is manufactured in EU

Request for a quote

MAKSAN INDUSTRIAL KITCHEN EQUIPMENTS

Turkey

GENERAL FEATURES -Stainless steel chassis construction -Thermostatically controlled -Highly efficient electric heating system -Double-glazed removable door system allows cleaning by the user -Perfect cooking with clockwise-anticlockwise fan system -Cooking cycle start at door closing -Safety thermostat provides safety -Interior design provides ease of cleaning -Lightning system provides clear visibility for foods -Water connection allows cooking foods with humidity -The flue outlet is controllable -User-friendly command interface -Plug and play feature for fast and efficient use -Motors and fans system is manufactured in EU

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 600 6 zone reflow soldering oven is the space saving and inexpensive solution for the numerous standard SMT soldering tasks. Taking up a small amount of floor space and having low energy consumption, the machine has all the advantages of a larger reflow soldering oven such as perfect thermal properties as well as comprehensive equipment including useful features.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven JUKI’s RS 800 8 zone reflow soldering oven embodies the best compromise between cost and effectiveness, floor space and energy consumption. With its 8 zones even complex soldering profiles can be constructed. 2 cooling zones ensure a suitable cooling down of the printed circuit boards after the soldering process.

Request for a quote

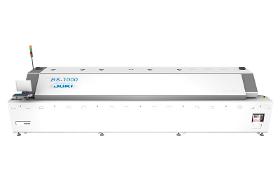

JUKI AUTOMATION SYSTEMS GMBH

Germany

Reflow Soldering Oven With its 10 heating zones and 2 cooling zones JUKI’s RS 1000 helps create even ambitious profiles and improve towards a high throughput of printed circuit boards respectively. Top flexibility is therefore guaranteed for future applications as well. In spite of a higher count of heating zones, the energy consumption is low.

Request for a quoteResults for

Industrial convection ovens - Import exportNumber of results

9 ProductsCountries

Company type