- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cut-to-length machines

Results for

Cut-to-length machines - Import export

BOSPORAS

Turkey

Deformations that are created by utilizing thermal cutting process causes metal materials to lose their flat form. The materials which are cut by a laser, plasma or oxygen cutter that utilize thermal process can become almost impossible to be in a desired flat form again. This is no longer an issue with the new generation leveler technology. Our new generation leveler touches almost every point of the sheet metal material and can smart process. That way, stressed material can be straightened.

Request for a quote

BOSPORAS

Turkey

BOSPORAS ADM-1600 coil slitting line, allows sheet metal materials to slit easily, heavy tonnage work to be done and user operator to work faster, easier and productive thanks to our technical team developing it with high-end technologies. BOSPORAS is always among the first ranks in its field with its technical team and many years of experience in coil slitting process while sharing all knowledge and high technologies with the iron-steel industry. Sturdy, effective and long-lasting slitting lines are manufactured with high costs but BOSPORAS investments, experiences and state-of-the-ark technologies offer the world-quality slitting lines for the lowest cost possible while prioritizing the customer satisfaction.

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACZ series compact servo feeder lines which have 600 and 1600 mm of coil width, between 2 and 10 mm thickness and 15.000 kilograms capacity is used as a compact press feeding machine. Our compact system servo feeder machines can process different kinds of materials like aluminum and other soft alloys, hot or cold foliated materials, carbon and stainless steel, high integrity materials and lamination steel. 11-Roller Compact Coil Servo Feeder System Components Hydraulic Decoiler Hydraulic Coil Car Hydraulic Inner Tightening and Unloading Automatic Coil Centering Feature Snubber and Upper Arm Coil Guidance Platform and Peeler Feature

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our AZP 11-roller straightener servo feeders work between 300 and 1600 mm of width and 1 and 6 mm of thickness. Our 11-roller bouncer straightener servo line consists bouncing system that works in harmony with the straightener rollers. It is designed using a different technique in order to make the piloting work on multi-phased progressive dies and for the coil to fed properly. Servo feeder and straightener models allows automated feeding to the AZP high performance presses. Servo engine stimulation gear ties the gapless designed gearbox and straightener rollers together. It allows the angle between the die and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. It feeds the coil materials in autonomous cycle, programmed speeds and high delicacy. Coil material feeding speed is 32 m / min.

Request for a quote

BOSPORAS

Turkey

ADS7 series 7-roller straightener servo feeder models work between 300 and 1600 mm of width and 0,5 and 4 mm of thickness. All of our 7-roller straightener servo machines utilize the piloting system and pinch rollers work synchronized with the straightener rollers. Bosporas produces 7-roller Model with static body and in accordance with CE Regulations. Our straightener servo feeders enable high performance automatic feeding to the presses. Servo feeder and straightener are merged and used in the same group. The practice of our models’ feeding system is easy to set up and to control. The angle between the feeder and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. Feeds the sheet metal in an automated cycle, pre-programmed speed and high delicacy.

Request for a quote

BOSPORAS

Turkey

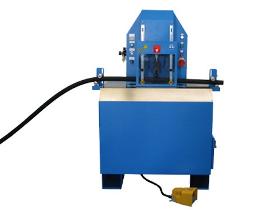

Our company BOSPORAS, mass produces AMD models with static body and in accordance with CE regulations. Our understanding of making the “quality” our top priority has made us the top choice among customers. AMD series mini straightener servo feeders are manufactured to have 0.3 and 3 mm of coil thickness and, 100 and 200 mm of coil width. AMD Model has a total of 7 4140-material rollers that consists HRC 58 and 60 surface hardness with 5 of them being a 60-millimeter straightener roller and 2 of them being an 84-millimeter pinch roller. AMD models don’t need any external guidance because they minimize the distance between Press body and the die. Our AMD model feeders are designed to control the press system easily with its 7” ergonomic LCD color display. Besides allowing Servo Feeder Straightener to work synchronized with the Press system, control panel can also work on systems like greasing the dies via PLC external output features, multi press control and piston die.

Request for a quote

BOSPORAS

Turkey

We keep on being a solutions partner to our valuable partners with our first-of-its-kind Mini Servo Feeder models that are manufactured and designed by our technical team via research and development. You can inspect our servo feeder which grants advantage from space and energy also decreases maintenance cost below and contact us for price or information you want.

Request for a quote

BOSPORAS

Turkey

The design and manufacture of this model belongs to Bosporas. AYK 15000 series hydraulic decoiler models have 15.000 kilograms of weight capacity. Our hydraulic decoiler machines work on 600 – 1300 – 1600 mm of coil width and thanks to hydraulic system, releasing and tightening features can be done automatically. If the grip and tightening process can’t be done according to the inner diameter of the coil manually, hydraulic engine mandrel systems can be used. Hydraulic system provides convenience and advantages when loading and unloading the coils for the companies by making the inner grip as tight as possible while holding the mandrel. The hydraulic coil car that is used in the process of loading and unloading the coils provides advantages like fast loading/unloading and convenience. Hydraulic coil car is an optional feature. Thanks to the circular Mandrels we used in our decoilers, the coils can be decoiled without any defect or fracture.

Request for a quote

BOSPORAS

Turkey

The design and manufacture of this model belongs to Bosporas. AYK 10000 series hydraulic decoiler models have 10.000 kilograms of weight capacity. Our hydraulic decoiler machines work on 600 – 1000 – 1300 mm of coil width and thanks to hydraulic system, releasing and tightening features can be done automatically. If the grip and tightening process can’t be done according to the inner diameter of the coil manually, hydraulic engine mandrel systems can be used. Hydraulic system provides convenience and advantages when loading and unloading the coils for the companies by making the inner grip as tight as possible while holding the mandrel. The hydraulic coil car that is used in the process of loading and unloading the coils provides advantages like fast loading/unloading and convenience. Hydraulic coil car is an optional feature.

Request for a quote

BOSPORAS

Turkey

Our model is designed and manufactured by Bosporas. AYK 6000 series Hydraulic mandrel motorized decoilers have 6000 kg of material carrying capacity. Our hydraulic decoiler machines work between 600 and 1000 mm of coil width and thanks to hydraulic system, releasing and tightening features can be done automatically. If the grip and tightening process can’t be done according to the inner diameter of the coil manually, hydraulic engine mandrel systems can be used. Hydraulic system provides convenience and advantages when loading and unloading the coils for the companies by making the inner grip as tight as possible while holding the coil on the mandrel. The hydraulic coil car that is used in the process of loading and unloading the coils provides advantages like fast loading/unloading and convenience. Hydraulic coil car is an optional feature. Thanks to the circular Mandrels we used in our decoilers, the coils can be decoiled without any defect or fracture.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 mm of width, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions. The Metzner ST-OB is for cutting cables & strands up to 30 mm diameter. Thanks to the gentle adjustment of the pressure between the transport belt also optimal for cutting rubber seals. WIDE SPECTRUM The cut-to-length machines of the ST-OB range have convincing precision, compact construction and processing spectrum for products such as cables, wires, braided cables, shrink-fit tubes, and numerous other materials.

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The Rotary Cutter RC is designed for the precise cutting of hoses and profiles made of rubber or plastic up to a maximum diameter of 100 mm and at line speeds of up to 300 m/min. A clean cut quality and minimized length tolerances characterize our rotary cutter. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Rotation Cutter RC Optimized cutting length tolerances through specially developed cam profile application Servo controller of the latest generation Low space requirement due to compact design High effectiveness with simple operation The Rotation Cutter RC at a glance A cut-to-length system with the highest quality The rotary cut-to-length RC machine meets your high quality requirements in many aspects.

Request for a quote

BIZERBA SE & CO. KG

Germany

Fully automatic slicer with integrated weighing technology for portioning and weighing of individual slices. With fully automatic product fixation. Easy to service and very robust – perfect for industrial use. Area of Use Robust slicer for industrial production

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quote

ZINSER GMBH

Germany

High-precision plasma cutting machines from ZINSER - efficient cutting solutions for all applications ZINSER GmbH offers a wide range of high-precision plasma cutting machines that are known for their outstanding cutting quality and efficiency. Our systems are specially designed to cut mild steel, stainless steel and aluminum with the highest precision. Thanks to the latest technology and a robust design, our plasma cutting systems ensure maximum productivity and reliability in industrial production. ZINSER 4025B / 4125B / 4026B / 4126B These premium plasma cutting machines offer excellent cutting quality and reliability for demanding applications. They are ideal for cutting thick and thin materials and are suitable for both simple and complex cutting tasks. ZINSER 2315 / 2325 / 2425 / 2426 Our economical plasma cutting machines offer a cost-effective solution without compromising on quality.

Request for a quote

EUROLASER GMBH

Germany

The cutting machine M-1600 offers laser cutting and engraving applications for the highest demands. With the optional eurolaser shuttle table system the productivity can be increased – offering a processing area of 1,330 mm x 1,630 mm (52.3" x 64.2"). This combination is ideal for applications like foils, acrylics, wood and textiles. The modular design enables eurolaser systems to be specially configured to suit every requirement. We analyze your requirements and configure the laser system individually for you. The usage of eurolaser laser machines enables you to process a wide range of materials, such as cutting of plastics, foams, textiles, adhesive foils, wood, acrylic, composite materials and much more. We are pleased to run a cutting test in our Application Center by using your individual material. Subsequently, you will receive a detailed test report in order to identify how your material was cut and engraved with our laser machines.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quoteResults for

Cut-to-length machines - Import exportNumber of results

51 ProductsCompany type