- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- combustion processes

Results for

Combustion processes - Import export

UNITED PROCESS CONTROLS GMBH

Germany

The PROTHERM 470 controller is designed to monitor, control, record, and archive combustion processes running in a furnace or simultaneously in multiple chambers. This powerful controller is suitable for various types of batch and continuous operations and can be installated on new, retrofit, or refurbished equipment. The fully configurable I/O channels can be used with oxygen sensors or any sensor with an analog output signal or Modbus communications. FEATURES • ½ DIN multi-loop embedded programmer with a color display and turn-and-push knob navigation • Up to 32 programmable PIDs included • built-in calculators for real-time carbon and/or nitrogen diffusion, and hardness profile • mathematical model for calculating atmospheric parameters • integrated web server for browser-based remote access. • works with internal and/or external I/O’s

Request for a quote

EXOTIC WHIP

Malta

Curious about the usability of Nitrous Oxide in Cars? We have put a brief blog together to understand how does nitrous oxide work in car racing, another genuine feature of this compound. While thinking creatively about Nitrous Oxide in Cars, the name of the famous action movie ‘Fast & Furious’ must have already crossed your mind. Well, the short burst of speed at the flick of a button is all a real deal. We prepared the following blog to understand this great use of nitrous oxide. *ExoticWhip Cream Chargers are not meant for car fueling. Our bottles are 100% foodgrade. This blog is merely informative. Nitrous oxide can serve many purposes. Among these is powering up your car’s engine. But how does it work? Incar racing, nitrous oxide works essentially as an accelerator of the combustion process; it boosts the oxygen levels of the engine. Meant simply, N2O acts as a supercharging system that offers extra vehicle power horsepower, for a short period.

Request for a quote

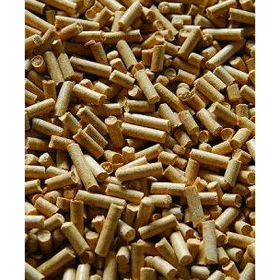

STARÝ TIMBER S.R.O.

Czech Rep.

We offer straw pellets for heating! Special technology has that the melting temperature is much higher than the usual straw pellets. Our pellets melting temperature is elevated from 800 0C to 1200 0C, an ash content of 4-7%. As a result is improved pellet combustion process and significantly decreased quantity of the formation slag . So, what about bedding in details ? Straw pellets, natural, super absorbent bedding made specially for horses and other farm animals. It is free of dust and really long lasting product comparing with shavings and other bedding used by farmers and horse enthusiasts.For producing straw pellets we are using locally sourced straw, which is ecologically clean product. 1 gram of our straw pellets can absorb 3.4 gram of water (see official test results), so bedding stays dry longer and that is why our straw pellets not exposed to freezing in cold winters. This protects animals from diseases and provide with maximum comfort.

Request for a quote

APROVIS

Germany

What you can expect with an APROVIS ActiCo: - Careful gas purification - Reduction of emissions - Damage prevention - Higher operational reliability - An improved combustion process - An extended activated carbon service life

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

High temperature combustion in gas flares is required when specific combustion parameters must be adhered to (TA Luft, governmental or local regulations) for reasons pertaining to the environment. One such parameter includes, but is not limited to, the emission of carbon dioxide (CO2) or nitrogen oxide (NOX). With special burner technology and a suitable combustion chamber suitable for temperatures > 1000 C, the ennox high temperature flare provides for and controls the correct combustion temperature. Our flares are designed to satisfy even the most demanding applications. At the heart of the NOXtreme flare control is the fully automatic control from the NOXmatic unit, which, if required can be extended to meet the actual project demands. The temperature control of the combustion process can be achieved either with a manual or automatic combustion air regulator.

KELVION HOLDING GMBH

Germany

The EGR Cooler, developed in close collaboration with our customers for medium and low speed engines, ensures that the recirculation exhaust-gas is mixed at the lowest possible temperature with the air for the combustion process. EGR Coolers are an essential element of EGR systems for the next engine generation which already now fulfills future emission guidelines according to IMO (International Maritime Organization), EPA (US Emission Protection Agency), EURO, etc. We have developed various cooler designs with regard to the different requirements of EGR Coolers at 2-stroke and 4-stroke engines. The patented design for 4-stroke engines high pressure EGR system enables cooling of exhaust gas, some of which are over 700 °C, down to 50 °C.

Request for a quote

EUROPEM

Belgium

Industries will generate Low CV waste gases, which are either difficult to burn or can contain insufficient energy to self-sustain the combustion process. For these applications, Europem developed the proprietary “ring-of-fire” Flare Tip. This tip has a ring of flame around the central waste gas tip thus ensuring complete oxidation of the low calorific waste gas. Both air assisted and non-assisted flare burners are available. Key features Proprietary design of HP sonic gas nozzle which maximises the entrainment of ambient air into the combustion zone Wind shield placed around the HP gas nozzles to prevent flame pull down Use of high grade alloys to enhance lifetime of the flare tip. Key advantages Smokeless operation at low heat radiation 100% smokeless turn down possible for air assisted HP flares Lower flare stack heights No need for any assist medium A low pressure flare can be integrated with the HP sonic flare to provide both HP and LP gas flaring in a single flare tip. Suitable for smokeless combustion of waste gas with entrained liquids Applications Upstream oil & gas sector Chemical and petrochemical industries including refineries Pipeline transport LNG and NG terminals and compressor stations

Request for a quote

EUROPEM

Belgium

A fluidised bed incinerator is the technology of choice for the combustion of many sludge streams or solid waste streams with a high moisture content. In a fluidised bed reactor, an inert material, typically calibrated quartz sand, is fluidised by blowing air through the bed. The sand bed expands and provides an ideal medium for the mixing of waste with combustion air. Because the fluidised bed is maintained at an elevated temperature, typically between 650°C and 800°C the water evaporates and volatile organic compounds mix with combustion air whilst escaping from the fluidised bed. EUROPEM fluidised bed reactors are bubbling fluidised beds with high turbulence. Different feeding systems can be supplied ranging from feeding screws and over spreader stokers to injection lances. Key Features Turbulent bubbling fluidized bed of inert material Different feeding systems for solid waste, waste liquids and waste gases Can be operated in a reducing or oxidising environment Key Advantages - Robust and flexible design to burn sludge or solid waste with high moisture content – Stable combustion process of waste with varying moisture content over time – Proven technology – Destruction efficiency over 99.99% and less than 1% carbon in the ashes – Low NOx and CO emissions possible – Flue gas treatment train needed to meet acid, heavy metal, dust and PCDD/F emission levels

Request for a quote

EUROPEM

Belgium

Ground flares can be either natural draft or forced draft, with or without temperature control and can be equipped with a single burner or with multiple burner arrangements: EP-PF Pipe Flare EP-EAS External Assist Steam EP-IAS Internal Assists Steam EP-EAS/IAS External/Internal Assist Steam EP-AA Air Assist EP-GA Gas Assist EP-CAA Compressed Air Assist EP-HP-PF High Pressure Pipe Flare EP-HP-MAS High Pressure Multi Arm Sonic EP-MP Multi Point EP-BP Burn Pit Special tailor made Flare Tips can be offered for specific applications. Europem Venturi Flame Shield (VFS) Europem has developed the proprietary Venturi Flame Shield giving double protection against flame lick. The VFS also pushes air up towards tip exit, leading to an enhanced and more stable combustion process. The VFS can be integrated into most Europem Flare Tips but is particularly suitable for H2S flares, ammonia flares, hydrocarbon flares and lean waste gas flares.

Request for a quote

EUROPEM

Belgium

Europem can supply complete flare systems as well as Flare Tips on their own for replacement or upgrade and refurbishment projects. The following standard Flare Tips are available: EP-PF Pipe Flare EP-EAS External Assist Steam EP-IAS Internal Assists Steam EP-EAS/IAS External/Internal Assist Steam EP-AA Air Assist EP-GA Gas Assist EP-CAA Compressed Air Assist EP-HP-PF High Pressure Pipe Flare EP-HP-MAS High Pressure Multi Arm Sonic EP-MP Multi Point EP-BP Burn Pit Special tailor made Flare Tips can be offered for specific applications. Europem Venturi Flame Shield (VFS) Europem has developed the proprietary Venturi Flame Shield giving double protection against flame lick. The VFS also pushes air up towards tip exit, leading to an enhanced and more stable combustion process. The VFS can be integrated into most Europem Flare Tips but is particularly suitable for H2S flares, ammonia flares, hydrocarbon flares and lean waste gas flares.

Request for a quote

EUROPEM

Belgium

In cases where waste liquid’s or suspension’s need to be incinerated, EUROPEM uses liquid fuel injection lances equipped with ultrasonic atomisation nozzles, resulting in very fine droplets and an almost gas-like combustion process. This nozzle uses an atomizing fluid such as superheated LP steam or compressed air. EUROPEM Natural Draft and Forced Draft Burners Different configurations for the atomization nozzle are possible, depending on the burner design, capacity range and the desired spray pattern in relation to the combustion chamber. The nozzle operates based on the Hartmann Generator principle and was originally developed the early 1970s. In 2007, the nozzle was optimized and now has a fuel turndown ratio of 10:1. Hartmann Generator principle: Through a jet nozzle (D), a gaseous fluid flows with supercritical pressure ratio – meaning sonic speed. According to Mach and Salcher a periodical structure will build up in the stream (dotted line). Graph K shows the pressure cycles along the length of the gas stream. Oscillations occur by filling (pressurizing) and deflating the hollow space H. This is the principle used for the Ultrasonic Nozzle. A Hartmann Generator is placed as a concentric ring around a central liquid fuel pipe. The high exit speed of the atomizing fluid (compressed air, steam or combustible gas) alone achieves a rough atomization, caused by the negative pressure. The ultrasonic effect created by the Hartmann Generator oscillates the pre-atomized droplets at a high frequency, and further fragments the droplets into a very fine mist. Advantages: Low and high viscosity fluids are atomized into smallest possible droplets. No limitation on ash content and other solid particles in liquid fuels. Various fuel types can be used in one nozzle, no limitation on fuel mixtures. High durability due to low operating pressure for fuel and atomizer. Different nozzle types to obtain different spraying paterns

Request for a quote

EUROPEM

Belgium

Enclosed ground flares are suitable for thermal destruction of a wide range of waste gases including rich and lean gas mixtures. Where the burners are housed in a cylindrical vessel resulting in the combustion process being out of sight and more controllable in comparison to elevated flares. Enclosed ground flares can also be designed with or without temperature control. With temperature control, a minimum residence time, at a specific combustion temperature can be set and guaranteed. Consequently, temperature controlled ground flares, also called combustors or thermal oxidisers, can meet the most stringent emission values. The emissions can be monitored with chemical emission monitoring (CEM) units. Features Can be equipped with Europem’ proprietary Tulip Venturi Burner for the combustion of lean waste gases or with multiple burners designed for the flaring of large capacities (modulated flaring is possible) Operating at varying temperatures depending on the load of the ground flare Smokeless operation and high destruction efficiency by ensuring some turbulence around the flame and sufficient residence time at elevated temperatures Simple control system, because the combustion temperature is allowed to fluctuate Provisions for support fuel in cases of combustion of lean waste gases or cooling air in cases of rich waste gas combustion Can be supplied as natural draft or forced draft system Can be supplied with or without temperature control Advantages No visible flame and reduced visibility of the installation due to lower stack heights Reduced noise levels Minimal heat radiation Possibility for emissions sampling High destruction efficiencies and smokeless operation Applications Tank farms and ship loading terminals Chemical and petrochemical industries Food processing industry Waste management plants

Request for a quote

ERC ADDITIV GMBH

Germany

ERC LPG GasLube Special with the special formula is designed for the protection of valves and valve seats in LPG-powered vehicles and is suitable for all commercially available additive dosing systems. Especially the heavy stressed inlet valves are protected. THE EFFECT As a result of the lubrication qualities lacking in the fuel for LPG operation, special additives must be supplied to the combustion chamber by means of a dosing unit for the optimal lubrication and protection of the valves against severe stress during the combustion process.

Request for a quote

ERC ADDITIV GMBH

Germany

ERC LPG GasLube Premium is designed for the protection of valves and valve seats in LPG-powered vehicles and is suitable for all commercially available additive dosing systems. THE EFFECT As a result of the lubrication qualities lacking in the fuel for LPG operation, special additives must be supplied to the combustion chamber by means of a dosing unit for the optimal lubrication and protection of the valves against severe stress during the combustion process. THE ADVANTAGES AT A GLANCE - Protects valves and valve seats against wear - Cleans the injectors and the fuel system - Reduces harmful emissions - Extends the engine service life - Tested by DEKRA

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Better fuel quality for combustion Blend fuel improvement Prevent sludge in case of fuel incompatibility Increases amount of burnable fuel Less wear and tear on engine components Optimization of combustion process Fuel treatment / conditioning Less clogged filters Areas of application The Homogenizer is a dynamic milling machine which can be used in the fuel system on board ships. It is designed to improve your fuel quality which will lead to a better combustion and less maintenance. Furthermore it can reduce sludge in case of fuel incompatibility. Increase the amount of burnable fuel in case of bad fuel quality. The Homogenizer has a high saving potential.

Request for a quote

NORIS GROUP GMBH

Germany

Compact and robust safety system for engines Safety system for engine emergency shut-down Compact and robust design for applications directly on engines Large number of preprogrammed engine types All inputs are monitored for wire breaks All connections are plug-in for easy installation Ideal for use in shipbuilding thanks to approvals from classification societies The safety system N3000-SAP has been developed for electrically monitoring the basic operating parameters of a combustion engine. It is the central unit for triggering an emergency shut-down of the engine to avoid damage. Thanks to its compact and robust design, it is particularly suitable for use on ships, directly on combustion engines. Signal processing with the safety system is purely digital. Together with fast, crystal-accurate speed acquisition, it ensures maximum safety and system reliability.

Request for a quote

PARKANEX SP. Z O.O.

Poland

Air supply from the outside The insert is equipped with a direct supply of air from the outside to the furnace. The air can be supplied through a 100mm diameter flex pipe or a 150x50mm rectangular duct . The damper knob is located in the upper part of the insert facade. Regulation of the air supplied to the combustion process The amount of air supplied to the combustion process is regulated by means of a knob located in the lower part of the façade. Air is taken from a direct air inlet and delivered under the grate and directly onto the glass, creating an air curtain that prevents excessive soiling of the glass.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PARKANEX SP. Z O.O.

Poland

Advantages of the UNIFLAM PRESTIGE fireplace insert Air supply from the outside The insert is equipped with a direct supply of air from the outside to the furnace. The air can be supplied through a 100mm diameter flex pipe or a 150x50mm rectangular duct . The damper knob is located in the upper part of the insert facade. Regulation of the air supplied to the combustion process The amount of air supplied to the combustion process is regulated by means of a knob located in the lower part of the façade. Air is taken from a direct air inlet and delivered under the grate and directly onto the glass, creating an air curtain that prevents excessive soiling of the glass.

Request for a quote

PARKANEX SP. Z O.O.

Poland

Regulation of the air supplied to the combustion process The amount of air supplied to the combustion process is regulated by means of a knob located in the lower part of the façade. Air is taken from a direct air inlet and delivered under the grate and directly onto the glass, creating an air curtain that prevents excessive soiling of the glass. Easy operation A capacious, pull-out ash pan drawer, a cast iron grate and an efficient system of air blowing onto the glass make the operation and maintenance of the fireplace easy and does not take much time. A wide view of the burning wood A modern, steel façade and a large corner pane with black decoration provide a perfect view of the fire from both sides of the fireplace. The handle and knobs made of stainless steel complete the whole, creating a modern style of the Uniflam Prestige

Request for a quote

PARKANEX SP. Z O.O.

Poland

Advantages of the UNIFLAM PRESTIGE fireplace insert Air supply from the outside The insert is equipped with a direct supply of air from the outside to the furnace. Air can be supplied through a 100mm diameter flex pipe or a 150x50mm rectangular duct The damper allows you to adjust the chimney draft and control the rate of combustion. The damper knob is located in the upper part of the insert facade. Regulation of the air supplied to the combustion process The amount of air supplied to the combustion process is regulated by means of a knob located in the lower part of the façade. Air is taken from a direct air inlet and delivered under the grate and directly onto the glass, creating an air curtain that prevents excessive soiling of the glass.

Request for a quote

SME INNOVATIONS LLC

Russia

Aerosol generator “MAG” is intended to extinguish fire of A,B,C and E classes in enclosed spaces. The extinguishing agent is safe for human and doesn’t require people evacuation. The fire extinguishing occurs due to a chemical reaction therefore interfering in combustion process with no oxygen isolation. The actuation of the generator occurs by means of linear heat detection under given temperature (short circuit of electric buttery takes place) or by means of Fipron-Cord when placed in the seat of fire.

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in combustion gases Control of processes and measurement of emissions. QAL1 compliant (EN14181) Brand : SETNAG ADVANTAGES : No need for reference gas: use of the MicroPoas® Semi in situ measurement (excellent reliability) Free circulation of the gases you analyse Easy and fast set-up Limited and cost-effective service and maintenance operation MEASUREMENT TECHNIQUE The S24N-2020 analyser fits CEM systems Oxygen measurement on wet gas (direct connection at heated hose outlet) Oxygen measurement on dry gas (after sample conditioning) EXAMPLES OFAPPLICATIONS Power generation, district heating operations... Incineration of industrial and domestic waste Steam production Steel works VOC incineration Control of processes...

Request for a quote

WOODPOWER WEST

Ukraine

The ‘tube’ shape with the central air chamber is specifically designed to help with airflow and circulation, meaning there’s more oxygen to improve the combustion process. These quadrangle charcoal briquettes are perfect for the grilling and cooking of meals with true heat in both indoor and outdoor settings. Their burning time is up to 5 hours on an open fire and the peak temperature is 800 degrees Celsius. Get the unparalleled heat and cooking quality of charcoal without a hint of smoke with these briquettes. Being totally smoke-free makes this charcoal perfect for both indoor and outdoor kitchens, making the cooking experience more versatile and comfortable, with no nasty smells or fumes. The advantage of charcoal briquette pini kay is the absence of harmful substances, 100% natural environmentally friendly product. This means you can cook with confidence that your food won’t suffer from contaminants. Natural Ukrainian Materials.

Request for a quote

WOODPOWER WEST

Ukraine

New generation charcoal from pini kay briquettes. The ‘tube’ shape with the central air chamber is specifically designed to help with airflow and circulation, meaning there’s more oxygen to improve the combustion process. These quadrangle charcoal briquettes are perfect for the grilling and cooking of meals with true heat in both indoor and outdoor settings. Their burning time is up to 5 hours on an open fire and the peak temperature is 800 degrees Celsius. Get the unparalleled heat and cooking quality of charcoal without a hint of smoke with these briquettes. Being totally smoke-free makes this charcoal perfect for both indoor and outdoor kitchens, making the cooking experience more versatile and comfortable, with no nasty smells or fumes. The advantage of charcoal briquette pini kay is the absence of harmful substances, 100% natural environmentally friendly product. This means you can cook with confidence that your food won’t suffer from contaminants.

Request for a quoteResults for

Combustion processes - Import exportNumber of results

25 ProductsCountries

Company type