- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chocolate line

Results for

Chocolate line - Import export

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: •Production line consisting of four stations: - Two automatic injectors. - One automatic dosing machine for chocolate coating. - Unit for spreading the topping on top of the coating. •A single urn keeps the injectors and the dosing machine heated, so that the product is kept at a stable temperature at which the dosing is smooth and trouble-free. •The line is no more than 5 metres long and can be operated by a single person at the start of the conveyor. •A double conveyor belt system moves the trays with the completed product to the start of the line. ADVANTAGES •High degree of automation in a small space, 5 metres. •Handled by a single operator. •Uniformity in the product.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

INCA VALLEY / INCA CAO

Belgium

Gastronomic metabolic friendly Chocolate. INCA'CAO achieved to create a gourmet artisan chocolate line in combination with food technology that is metabolically friendly and accessible to a large audience. INCA’CAO uses a specific sweetener combination so our products have a very low glycemic index An innovative sweetener combination with responsible ingredients that the body produces itself. In this way, we value the well-being of our customers without having to put gastronomy aside. Supporting ingredients with no negative side effects. Despite the fact that sugar does not have an expiration date, it is outdated for us. We appreciate “metabolic flexibility”.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Using our equipment for chocolate production you can ; To produce a wide range of chocolate types in an one production line, Chocolate production in different colors and shapes, switch quickly from one product to another, To expand the diversity of the masses with each other and with wafer, cookies and other combinations by increasing the variety of forms, making filling and confectionery,Any mass can be used: chocolate, caramel, praline masses, nougat, halva, marzipan, dried fruits, fondant, soufflé, marmalade etc. Almost completely free from manual labor.

Request for a quote

SMARTMAK

Turkey

Chocolate Enrobing Line provides a practical and fast solution for dipping products with chocolate, such as dates, pastries, biscuits and various fruits such as strawberries. Chocolate can be used in liquid or granular form.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

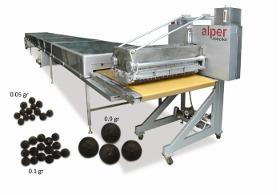

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

rop Line Chocolate drop size can be adjusted between 0.05 to 0.9 gr Each drop has its own piston Depositor has high precision since dosing is done by servo-motors. Depositor hopper is double jacketed and temperature controlled Depositor has agitator Easy cleaning PLC controlled Capacity: 33-600 Kg/hour

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 8-10 moulds/min. for 2500kg blocks 4-5 moulds/min. for 5000kg blocks Capacity : 1200-1500 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 90.000 kcal/hour Cooling Tunnel : Tower type cooling Couverture Moulding Line (KDH – 750) Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 4-5 moulds/min. for 2500kg blocks 2-3 moulds/min. for 5000kg blocks Capacity : 600-750 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 45.

Request for a quoteResults for

Chocolate line - Import exportNumber of results

8 ProductsCountries

Company type