- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brass alloys

Results for

Brass alloys - Import export

KIGEMA SP. Z.O.O

Poland

Brass - is widely used in technology and, after light alloys, they are the most common alloys of the non-ferrous metal group.

Request for a quote

JINTIAN COPPER

Germany

Main products: HPb59-1、HPb60-2、H62 and other grades of leaded brass plates Product characteristics: Strong corrosion resistance, good elasticity, good formability and weldability, good strength Applications: Copper key blanks, copper engraving, electronic connectors, handicrafts Production capacity: 25,000 tons Honorary titles: Zhejiang Famous Brand Product, China's Top 5 Copper Strip Company

Request for a quote

PJSC VERKHNEDNEPROVSKIY FOUNDRY MECHANICAL PLANT

Ukraine

Our factory offer wide range of brass bars and brass pipes. If you interested in purchasing please contact us.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the products used in fashion decoration products.The material are aluminum alloy,zinc alloy and brass and so on...

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin: China Shape: as required Length: Customized Grade: Brass Cu (Min): 57%-59% Alloy Or Not: is Alloy Type: copper bar Certification: SGS MOQ: 100 kgs OEM Service: Accept Supply Ability: 50 Ton/Tons per Week Packaging Details:standard export packing Port of shipment:Xiamen,China Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of origin: China Model Number: C21000 C22000 C23000 C36000 Application: Industry construction Shape: Round Length: 1-10m Size: 1-800mm diameter Grade: brass Cu (Min): 63% Surface: Polished Standard: IS ASTM DIN EN ISO Package: Standard Seaworthy Package Delivery time:15-30 Days Supply Ability: 20 Ton/Tons per Day Packaging Details: Standard export package. Payment term:T/T,L/C etc. Port of shipment: Xiamen,China Excellent cutting, drilling performance, high strength, good electrical conductivity, strong corrosion resistance. Applicable for automatic lathe, CNC lathe processing products, such as the hardware, electrical connectors, connector etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Turned parts, CNC turned parts, long turned parts Part diameter: 0.3 to 200 mm Parts Length: 1000 mm Materials: steel, stainless steel, brass, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR,C45 Stainless steel: SS303, SS304, SS316L Non-ferrous metal: Brass, Alu, Ti alloy Plastic: POM, PP, PE, ABS Process: Turning/Milling/CNC Boring/Drilling/Threading Grinding Application: Agricultural machinery General machinery Hydraulic cylinders Telecommunication

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

DIETZ GMBH

Germany

Production to order – also with special-purpose materials as required: We only produce in accordance with customer specifications. Compression springs can assume a wide variety of designs and forms. Our production facilities include compression springs with wire thicknesses in the range of 0.30 to 3.00 mm with abraded ends and in the range of 0.10 to 4.00 mm with unabraded ends. Even extremely strict tolerances regarding length and strength are adhered to in our compression spring production facility. Special-purpose materials that meet specific requirements can also be integrated into production without any problems. Wire materials: All standard spring steel wires in accordance with EN 10270. Non-ferrous wires made of copper, brass and bronze. Special alloys such as: Hasteloy, CuNi44, NbZr1, TaW2. Other materials on request.

Request for a quote

NORELEM FRANCE

France

Self-tapping threaded inserts for making high-strength, wear-free, vibration resistant screw connections in materials with low shear strength such as aluminium and aluminium alloys, brass, bronze, cast iron, duro and thermoplastics. The threaded inserts are tapered at the bottom and have a cutting slot. By screwing in they cut their own threads inside a receiver hole. This guarantees a completely secure and firm anchoring in the host material. Internal thread D1 acc. to ISO 6H. The threaded inserts with cutting slot spring slightly inwards in the slot region in some materials. This results in a screw locking effect. If this is not desired, we recommend the threaded inserts with a cutting bore.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

APPLICATION — Refrigerant charging hose with compact ball valve deigned to meet 1/4" SAE requirement for refrigerant permutation, fit most refrigerants like R134A. R22, R12, R502, R404. Standard 1/4* female fl3re fittings with a valve core depressor and 450bend on ore end for convenient access to the system. HIGH WORKING PRESSURE — Working Pressure: 800 PSI; Burst Pressure: 4000 PSI. Hose and ball valves with 1/4" SAE thread can oe fitted most refrigerants. Note: R410 and R32 refrigerants with 1/4" SAE x S/16* SAE, if you want to use it on R410 and R32 refrigerants please use a M-1/4" SAE x F-5/16* SAE Adapter. EASY INSTALLATION — 3 colors 60" (Sftl hoses coded in red. blue ar.d yellow, and all completed with compact ball valve and plastic handles on each hose.The coupler nuts are deeply knurled for quick finger-tightening. PREMIUM QUALITY — Refrigerant 3-color charging hoses made of high-quality brass alloy and ruDoer, last long

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

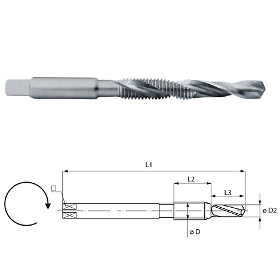

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

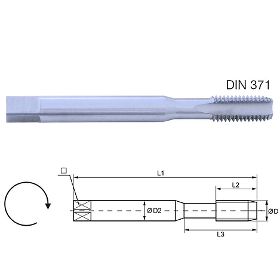

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For brass Material of product: HSSE Surface treatment: TIN For materials: Brass (short chipping) Tensile strength up to: 600 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Due the cutting geometry specially recommended for applications in Copper-zinc alloy (Brass) - short-chipping. Tap for machine use in blind and through holes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China CNC Turning Factory, Custom hose nozzles from stainless steel, carbon steel with zinc plated, chromed, PVD coating, aluminum alloy, brass.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg have a freind factory which specialize in Hot forging services, we can outsourcing the rough parts from hot forged parts, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you have any parts suit for hot forging process, welcome contact with us to check it.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in custom manufacturing various sheet metal stamping & forming with high quality,can provide relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, we provide one-stop services for metal stamping parts. Materials Available Cold Rolled Steel Stainless Steel Hot Rolled Steel Aluminum Alloys Brass and Bronze Alloys We are professional metal stamping factory from China Ningbo, we have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, If you are interest in our custom metal stamping services, welcome send your design and requirements to us, we shall work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg provide large size steel parts machining services, we can outsourcing the rough parts from hot forging,steel bars,pipes,orin castings,die castings, then machining it to final parts.Can effectively reduce the production cost and improve the production speed, as well as product quality. The hot forging process can produce steel products of all sizes and shapes,the forged parts have higher density and strength and are suitable for the production of various valve and pipe fittings,such as flanges, rings... We can forge stainless steel 304,316, brass, aluminum alloy, carbon steel, alloy steel and other materials. If you need any large size steel parts, welcome contact with us to check it.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating of chrome/zinc/nickel plated, tinning,copperize,Colour spray-painting, blackening, hot-dip galvanizing, tephlon plating, etc. We provide precision CNC turning & Milling Services for producing high Precision Turning Parts for worldwide customers.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turned Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating If you have any steel connecting rods need to be machined, please feel free to contact us for a offer.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Turned Parts manufacturing more than 20 years, We have introduced various types of precision CNC lathes to process high precision and high finish turning parts. Name: CNC Turned Parts,Hose Coupling Material: Stainless Steel,Carbon Steel, Aluminum Alloy,Brass Finish: Natural, passivation for stainless steel,anodizing & anodine for aluminum,zinc plating,chrome plating,nickel plating,hot galvanizing heat treating,oiled for carbon steels, etc. Machined type: CNC Turning, CNC Milling, CNC Boring, CNC Threading,Tool Milling,etc. China CNC Turned Parts Manufacturer custom produce all kinds of turned parts according to customer’s drawing or samples, we can produces stainless steel Turned parts,carbon steel Turned parts, aluminum turned parts,brass & copper turned parts. If you are interest in our CNC turning services, welcome send us a inquiry, then we can discuss about your turning parts project !

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turned Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating If you have any turned parts need to develop, welcome contact us to discuss your project. we will offer a competitive price to you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Stainless Steel Assembly Parts shows in pictures are made from SS304, Customer from Italy. It's made from hot forged rough parts,then machined to the final parts, machining processes are CNC turning and Milling. Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Materials: Carbon Steels,Alloy steels,Tool Steels,Stainless Steels,Aluminum Alloys,Brass & Copper. Finish treating: Anodizing,hard anodizing,electroplating

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in custom manufacturing various sheet metal hinges with high quality. we are professional sheet metal stamping manufacturer from China Ningbo, we have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, also we have produced many kinds of metal hinges for foreign customers, we provide one-stop services for metal stamping parts. Materials Available Cold Rolled Steel Stainless Steel Hot Rolled Steel Aluminum Alloys Brass If you are interest in our custom metal stamping services, or have any metal hinges need to be customzied,welcome send your design and requirements to us, we shall work a more competitive price for you. China metal stamping manufacturer custom produce Metal Hinge according to customers’ drawing or samples. If you have designed new metal hinge need to be customized from China, please don’t hesitate to contact with us.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Turned Parts manufacturing more than 20 years, We have introduced various types of precision CNC lathes to process high precision and high finish CNC turned parts. Name: CNC Turned Parts With Texture Of Decorative Design, Handle Body Material: Stainless Steel,Carbon Steel, Aluminum Alloy,Brass Finish: Natural, passivation for stainless steel,anodizing & anodine for aluminum,zinc plating,chrome plating,nickel plating,hot galvanizing heat treating,oiled for carbon steels, etc. Machined type: CNC Turning, CNC Milling, CNC Boring, CNC Threading,Tool Milling,etc. China CNC Turned Parts Manufacturer custom produce all kinds of turned parts according to customer’s drawing or samples, we can produces stainless steel Turned parts,carbon steel Turned parts, aluminum turned parts,brass & copper turned parts. Want to custom precision CNC turned parts? Welcome send us a inquiry, then we can discuss about your turning parts project !

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Turned Parts manufacturing more than 20 years, We have introduced various types of precision CNC lathes to process high precision and high finish CNC turned parts. Name: CNC Turned Parts With Texture Of Decorative Design, Handle Body Material: Stainless Steel,Carbon Steel, Aluminum Alloy,Brass Finish: Natural, passivation for stainless steel,anodizing & anodine for aluminum,zinc plating,chrome plating,nickel plating,hot galvanizing heat treating,oiled for carbon steels, etc. Machined type: CNC Turning, CNC Milling, CNC Boring, CNC Threading,Tool Milling,etc. China CNC Turned Parts Manufacturer custom produce all kinds of turned parts according to customer’s drawing or samples, we can produces stainless steel Turned parts,carbon steel Turned parts, aluminum turned parts,brass & copper turned parts. Want to custom precision CNC turned parts? Welcome send us a inquiry, then we can discuss about your turning parts project !

Request for a quoteResults for

Brass alloys - Import exportNumber of results

73 ProductsCountries

Company type

Category

- Turning - steels and metals (10)

- Machine tools, metal machining - parts and accessories (9)

- Bathroom accessories (7)

- Sheet metals - stamping (4)

- Brass (3)

- Bags, plastic (3)

- Pipes and tubes, copper (3)

- Foundries - copper, bronze and brass (2)

- Couplings, mechanical (2)

- SMALL METAL PARTS (2)

- Tools & Hardware (2)

- Aluminium alloys (1)

- Bathroom installations - items for the disabled (1)

- Casting of special and high-grade steels (1)

- Centrifugal pumps (1)

- Construction Materials (1)

- Coupling, pneumatic (1)

- Disinfectants, non-medical (1)

- ELECTRIC EQUIPMENT (1)

- Electricity - distribution (1)