- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- belt maintenance

Results for

Belt maintenance - Import export

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt Company offers a range of belt maintenance tools for easy removal, repair or installation of metal conveyor belts. All tools are packaged in a reusable storage sleeve to help maintain the tools precision and cleanliness.

Request for a quote

FORBO SIEGLING GMBH

Germany

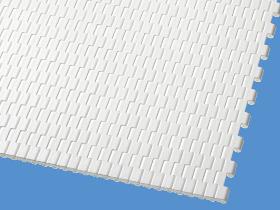

Straight running belts, Pitch 12.7 mm (0.50 in) Belts for medium-duty food and non-food applications Design characteristics Mini pitch belt with small transfer gap robust design guarantees superior durability and high belt pull capacity Design for smooth run on 19 mm (0.75 in) nose bar Headless pin system making it easy to install and remove the belt for maintenance Closed, solid belt edge to prevent belt edge damages Components: Sprockets in different sizes with round or square sprocket bore Detail hinge pin Headless one-piece pin with unique retention system ensures trouble free installation and maintenance

Request for a quote

FORBO SIEGLING GMBH

Germany

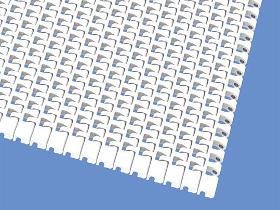

Straight running belts, Pitch 8 mm (0.31 in) Belts for light to medium-duty food and non-food Design characteristics Micro pitch belt with small transfer gaps Designed to run over nosebars/knife edges or rollers with a radius down to 3 mm (0.12 in) allowing, precise transfer of even the smallest products Versatile for conveying, drying and cooling applications Optimal design of sprocket teeth, and belt underside provides superior sprocket engagement, safe belt tracking and favorable cleanability Belt and sprocket design ensures superior load transmission and belt pull capacity Headless pin making it very easy to install and remove the belt for maintenance Components: Sprockets In different sizes with round or square sprocket Detail hinge pin Headless pin with unique shoulder design ensures trouble free instal- lation, maintenance and a secure pin retention Detail nose bar Narrow transfer gap ensures smooth transfer of small and delicate products

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko High Speed Manipulators are designed for extremely rough environmental conditions. Due to their encapsulated design, the ingress of dirt is impossible, while at the same time high loads up to 300kg can be handled. Driven by a powerful servo motor and a low-maintenance toothed belt drive, extreme accelerations up to 15m/s² are possible. Due to this simple and ingenious design, the manipulator can be integrated in all forging lines. Different spraying tools are possible to meet every task The manipulators can be modularly equipped with several independent axes. This design saves money and increases the productivity of your forging line! Many optional extras can be configured to meet all requirements.

Request for a quoteResults for

Belt maintenance - Import exportNumber of results

7 ProductsCountries

Company type