- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assembly of production lines

Results for

Assembly of production lines - Import export

ID GROUP

France

production and assembly lines, static stations in an industrial or commercial environment, sorting centers, etc. Environment: dry or slightly wet Advantages: the honeycomb bottom provides excellent cushioning during long standing positions bevelled edges to avoid the risk of falling antislip surface thanks to its treadplate look surface thermal insulation soundproofing interlocking easy to install the yellow edges delimit the safety zones Colors: black with yellow borders

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic operating principle Extremely insensitive to contamination such as oil mist, moisture and dust Due to the Ø 20mm clamping shaft extremely robust against oscillations and vibrations Perfectly suited for automated data acquisition in measuring fixtures, assembly and production lines

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High precision incremental length probe with magnetic operating principle Extremely insensitive to contamination such as oil mist, moisture and dust Due to the Ø 20mm clamping shaft extremely robust against oscillations and vibrations Perfectly suited for automated data acquisition in measuring devices, assembly and production lines

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High precision incremental length probe with magnetic operating principle Extremely insensitive to contamination such as oil mist, moisture and dust Due to the Ø 20mm clamping shaft extremely robust against oscillations and vibrations Perfectly suited for automated data acquisition in measuring devices, assembly and production lines

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High accuarcy incremental length probe with magnetic operating principle. Extremely insensitive to contamination such as oil mist, moisture and dust Due to the Ø 20mm clamping shaft extremely robust against oscillations and vibrations Perfectly suited for automated data acquisition in measuring devices, assembly and production lines

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

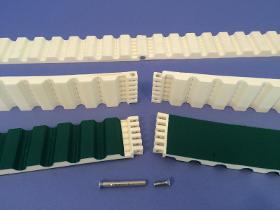

PU timing belts with easy joint as strong as a welded joint The easy joint timing belt fastener is the perfect solution, for a quick and easy mechanical endless connection of PU timing belts. Assemble without disassembling, without stopping your production line Replace your belts in few minutes without disassemble your hoods, pulleys, axis. Reduce your production downtimes. The method of mechanical assembly and fastening system easy joint offers unique solutions for easy and fast repairs of power transmission belts or conveyor belts. Pitches: H / T10 / AT10 / T20 / AT20 / 8M / 14M Standard: Polyurethane 90° Shore A grey Versions: Standard, PAZ, PAR Cords: reinforced with a Polymercord around the Pin in each tooth joint, arranged in parallel Width: from 10 to 150mm, (wide belts possible on request)

Request for a quote

MIRO GLOVES

Czech Rep.

AntiCut Soft1 The glove consists of two layers the outside layer is from polyamide (abrasion resistant) and the inner layer is from cotton that creates a comfortable environment for hands. Due to the use of elastic materials, the gloves are very flexible and easily adapt to the shape and size of the hand. Preferably used in places where you need to handle small objects, on assembly lines, in the production of electronics, anywhere there is a risk of dirt, scratches or abrasions at work.

Request for a quote

BERNSTEIN AG

Germany

When it comes to maximum safety on the assembly line, in the production line, or directly at the machine, the Safety Rope Pull Switches from BERNSTEIN AG are a reliable and proven solution. BERNSTEIN has added a particularly small and compact version to the product family of safety rope pull switches. Thanks to its modular design, the SRO (Safety Rope Pull) is extremely space-saving as well as being highly versatile. The modular principle has the advantage of always being able to offer exactly the right product for a specific customer application.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Trinmak designs the most suitable systems for you, including complete assembly and service services for manual or automatic workstations, so that your production lines in your factory can be operated with high efficiency and ergonomic principles in accordance with contemporary production systems.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

YONGMING MACHINERY MANUFACTURING CO., LTD

China

TFBGZ-400 is the pumpkin seeds shelling machine with seed shelling, sorting and shells removing. The processing materials have high commodity are ensured by systematic shelling procedures, screw transportation, efficient de-huller and vibration separating sieve assembly. The production begins with raw materials being fed in the dehuller and then shelled materials, the kernels separate from covers through vibration sieve, and remove broken kernels. Then the shells are removed using cyclone, seeds and kernel fall into second layer of sieve and continue to be screening, kernels come to finished kernel outlet, at same time, secondary shelling for unshelled seeds from procedures. The equipment can be used with the assembly line, increasing production capacity and reducing production costs effectively.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes or hoses for windshield and headlamp washer systems can be supplied with one or two mounted Quick connectors as fully assembled units. The Quick connector is a reliable way to connect a corrugated tube to the connecting cuff and allows for quick and easy assembly or disassembly. Our product line includes a wide range of accessories and diameters. Application: Automotive, agricultural machinery and construction engines; for applications in headlight cleaning systems

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes and smooth tubes with connecting elements are made to customers specifications for use in low pressure duct systems. This guarantees a reliable connection and an easy and time-saving assembly and disassembly. Our product line includes a wide range of nominal sizes and line of matched accessories. Available materials/maximum operating temperature: PP/PA 110°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines; in applications that require a small bend radius and/or dynamic stress environments, ventilation systems, connecting lines between various components for vacuum conveying systems

Request for a quote

MG ELECTRICIDAD

Spain

At we offer various types of services related to electricity. We can manufacture any electrical installation and do maintenance of electrical panels with UL Certification and reconditioning of electrical panels with CE marking. We are specialists in industrial electrical installations since 1979. We advise you on how to automate the installation of your factory and optimize its resources. We carry out maintenance of electrical installations, automation of industrial processes, production lines, assembly of electrical panels with their corresponding diagrams, programming, etc.

Request for a quote

COMERC SP. Z O.O.

Poland

We design, manufacture, build, train and service The pellet production lines designed and installed by our company offer capacities ranging from 2 t/h to 20 t/h. The capacity achieved naturally depends on the number and power of the machines and equipment comprising the production line. Pellet production lines – the offer: •design (technical conceptual design, formal arrangements, technical documentation, manuals, cost calculation), •supply (machines, devices, measuring and control apparatus, control cabinets, and all installation materials), •installation (machines, devices, control cabinets, measurement, control and feed wiring, post-installation testing, acceptance measurements), •software (controllers, operator panels, visualisation and control systems), •commissioning (machines, devices, control cabinets, control and power installations), •training process operators, programmers and IT technicians and technical human resources, •service within the warranty period and beyon

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The chili selecting production line is the latest production line developed by our company. Its main function is to improve the quality of chilis through sorting and grading. This production line has a reasonable design, large production capacity, strong practicality, good selection effect, and other characteristics.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YONGMING MACHINERY MANUFACTURING CO., LTD

China

Based on years of experience in oilseed pressing and processing, Yongming machinery has designed two processes: cold pressing and hot pressing. The cold pressing process can retain active nutrients, reduce the color of crude oil, and produce oil with a strong flavor when using the hot pressing process to meet the needs of different users. Moreover, the oil yield is high and the production cost is low. The entire production line is equipped with advanced cleaning, pressing technology, and refining technology while paying attention to energy conservation and environmental protection, reducing emissions, saving costs, and maximizing corporate profits. Given the environmental protection and workshop hygiene requirements of modern industry, this production line is equipped with a complete dust removal system, and all connections for material transportation are equipped with suction to meet production and environmental protection requirements.

Request for a quote

SMARTMAK

Turkey

Tomato sauce production line starts from Fresh tomato to final packaged product. Tomatoes undergo several processes including washing, sorting, crushing, concentrating, filling and packaging according to customer's demands.

Request for a quoteResults for

Assembly of production lines - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Precision measuring instruments (4)

- Automation - systems and equipment (2)

- Hoses, pipes and tubes - plastic (2)

- Packing and packaging - machinery and equipment (2)

- Conveyor belts (1)

- Electric and electronic components - machines for manufacturing (1)

- Fabric gloves (1)

- Food Industry - Machines & Equipment (1)

- Food Processing (1)

- Food canning and preserving - machinery and equipment (1)

- Measurement - Equipment & Instruments (1)

- Oils, cooking - machinery and equipment (1)

- Safety shields for machines (1)

- Sheets, rubber (1)

- Steels and metals - forming and cutting (1)