- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinable ceramics

Results for

Machinable ceramics - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

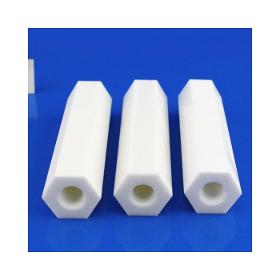

Electrical Insulation Macor Rod: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Rod for Heating Element Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Rod Applications 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Valve Core For Coca-Cola Machine Alumina ceramic valve core for a Coca-Cola machine refers to a component used in the dispensing system of the machine that controls the flow of the beverage. The valve core is a small, cylindrical piece made of ceramic material that is inserted into the machine's dispensing mechanism. The use of ceramic valve cores in Coca-Cola machines is preferred over other materials such as plastic or metal due to their durability and resistance to corrosion. Ceramics is also an excellent material for maintaining the flavor of the beverage as it is non-reactive, meaning it does not absorb any flavors or odors from the beverage. The valve core is responsible for regulating the flow of the beverage through the machine's dispensing system, controlling the amount of liquid dispensed per use. It is an essential component of the machine and should be regularly maintained to ensure optimal performance.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

PRECISION CERAMICS

United Kingdom

Macor Machinable Glass Ceramic is one of the most versatile and unique technical ceramics available and as you would expect from Corning’s principal, longest serving and highly-respected UK distributor, Precision Ceramics offers a complete, fast turnaround, research and development, design, prototyping and manufacturing service which is second to none! We’re also experts in Macor Machining and Metallization.

Request for a quote

PEEKCHINA CO., LTD.

China

Ceramic PEEK Material Discover the art of precision engineering with Ceramic Filled PEEK Rods. Their exceptional machinability enables manufacturers to achieve intricate designs and complex shapes effortlessly. Combined with high strength and good stiffness, these rods ensure your components maintain their integrity, even under demanding conditions. Trust in Ceramic Filled PEEK Rods for reliable performance and seamless machining, elevating your projects to new levels of excellence.

Request for a quote

PRECISION CERAMICS

United Kingdom

Precision Ceramics is a Shapal Distributor. Precision Ceramics is a Shapal Expert. In fact, there is no other Shapal Supplier who knows more about this unique machinable ceramic than Precision Ceramics. We’re simply experts in everything Shapal.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Cleaning of cooling devices, beverage and goods vending machines Cleaning of tiles, ceramics or natural stone Cleaning of construction machines and lorries, tarpaulins Cleaning of machine tools and workshop floors Advantages and benefits NSF A1 registered No classification marks according to (EG) No. 1272/2008 Free of organic solvents and phosphates Readily biodegradable Good separation behaviour Gentle to plastics, seals, rubber and sensitive metal surfaces Depending on the degree of soiling, can be diluted up to 1:10 Suitable for use with high-pressure cleaners MOSH/MOAH-free

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The extreme hardness and angular yet sharp-edged properties is typical of black silicon carbide type WIWOX® SI. It is particularly suitable to machine hardened steel and ceramics. It consists of crystalline silicon carbide, which is produced from silica sand and petroleum coke in electric resistance furnaces at temperatures of > 2.300° C. Silicon carbide is iron-free, angular and extremely hard.

Request for a quote

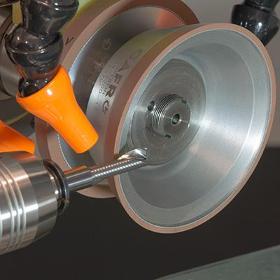

WMC SINTERSTAR AG

Switzerland

WMC Sinterstar AG represents the company Mirka (Cafro) in Switzerland. Cafro diamond and CBN grinding wheels are characterised by innovative bonds and high cutting ability for machining hard metal, ceramics and steel. Cafro's core competence is the production of resin bonded diamond and CBN grinding wheels. Over the years, the company has also specialised in the manufacture of metal-, hybrid-, ceramic-bonded and electroplated grinding wheels and PCD/PCBN tools. Our employees will also find the optimal grinding solution for your company. We benefit from our own knowledge and experience as a carbide manufacturer.

Request for a quote

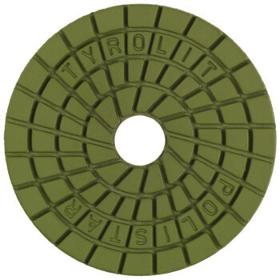

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit's range of polishing pads caters to the varying polishing needs of different stone materials. Harder stones like granite, with a hardness of 5 or more, require more grinding pressure, while marble, with a hardness of 3 to 4, is considered softer. Terrazzo's hardness depends on its manufacturing materials. Tyrolit polishing pads, combined with appropriate supporting discs, ensure proper polishing. These discs are essential for converting an angle grinder into a polishing machine. Tyrolit’s ceramic polishing pads feature velcro backings for easy attachment to the supporting disc. Tyrolit’s ceramic polishing pads and supporting discs are perfect for polishing stone surfaces. Our assortment includes grit sizes from 50 to 3,000, ensuring a perfect finish on materials like granite, marble, and terrazzo. Tyrolit offers professional stone workers a top-tier selection for efficient, high-quality stone polishing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Laser Ceramic Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina cearmic bar is used when conditions exclude the use of metal, either for chemical reasons or because of excessive temperatures.Their main applications are between 1000 and 1800°C. They may be in directly contact with the medium or may be used as a gas-tight inner sheath to separate the thermocouple from the actual metal protection tube. Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses. Evenhair-line cracks can lead to contamination of the thermocouple resulting in drift or failure. High purity ceramic strip provide a broad range of engineering properties: High Temperature-Superior Strength-Corrosion Resistance-Thermal & Electrical Insulation along with other specialized characteristics. -Precision Close, Tight Tolerances, -Ceramic Bar & Ceramic Strip machined to customer specifications-Prototype to Production-Intricate ceramic machining -Alumina is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The crucible is produced by depositing pyrolytic boron nitride upon a mandrel having the shape of the desired crucible at a temperature of from about 1850° C. to about 2100° C. until a first layer of boron nitride of suitable thickness has been produced, interrupting the deposition of boron nitride upon the mandrel and lowering the temperature to below 1750° C., and then depositing additional boron nitride upon the mandrel at a temperature of from about 1850° C. to about 2100° C. to produce a second outer layer of boron nitride having a thickness greater than that of the inner layer. Features and Benefits of Boron Nitride ceramic 1. Easily Machinable 2. Exceptional Heat Resistance 3. High Thermal Conductivity 4. Low Thermal Expansion, Excellent Thermal Shock Resistance 5. Outstanding Electrical Insulation - even at high temperatures 6. High wet resistance to molten metals, slags and glass 7. Extreme Corrosion and Wear Resistance

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quotePOUGET

France

USE : - Descaling rails (Stepping-up, Preparing Connection Welds, Laying Silencers in the rail Web). - Grinding Rail Corrugation with Abrasive Belt (for NB-15 Rail Grinding and Scrubber) - Cleaning of Bolts and Coachscrews on Tracks. ADVANTAGES : High Effetctive and Quality Results. * Descaling Brushes with hardened Steel Wires External Ø (mm) Reference 60 1097-R 80 1097-M 100 1097-P 120 1097 * Lamella Brushes with Ø 8 mm Rod - Width 30 m m. External Ø (mm) Reference 60 1039-P 80 1039-Q 100 1039-R * Metallic Cup-Brush Ø 230 mm To clean Bolts and Coachscrews - Ref. B-230 (Suitable of J.10, T-11, and J-12 Machines) * Ceramic Abrasive Belts (for NB-15 Grinding and Scrubber Machine) - Rail Corrugation Grinding. - Width = 60 mm : * Heavy-Grain ( Rough) - Ref. BAC-24 * Fine-Grain ( Finish) - Ref. BAZ-36 These Belts allow to grind about 1000 meters of rail.

Request for a quote

MICROCERTEC

France

Quartz, or fused silica, can be machined like any other ceramic material thanks to diamond tools. Thus Microcertec can realize customized parts made of quartz with various sizes and shapes, high level of precision but without any optical required performances or surface finish. The most important properties of the quartz is its low coefficient of thermal expansion. From an optical point of view, the quartz is generally transparent to the infra-red wavelenghts. Selection of materials Microcertec uses standard grades of quartz from well-known producers like GE or Heraeus. We machine both quartz standard quality as well as semiconductor and optical grade quartz. Properties From a general point of view, quartz shows : - good electrical insulation - very small coefficient of thermal expansion - good thermal insulation - good thermal resistance - transparence to the infra-reds - vaccum resistance Our typical applications Quartz is mainly used as : - electrical insulators - thermal...

Request for a quote

MICROCERTEC

France

Macor® is most used for its machinability. Softer as the other ceramic materials, Macor® allows fast turnaround to obtain complex structures with tight tolerances. Macor® can be grinded and facilitate the drilling and milling operations. Selection of materials Microcertec uses Macor® from the comapny Corning. Macor® is a glass ceramic from Silica (50%) and also with Magnesium und Aluminium. Properties Macor® have the following features : machinability good electrical insulation good thermal insulation dimensional stability vacuum resistant Our typical applications Macor® is widely used in the following applications : tools for the machine in production insulator electrode holders sensor holders lense holders mulberry outlet Download Material properties datasheet : ceramics and quartz (1472 Ko)

Request for a quote

MICROCERTEC

France

Quartz, or fused silica, can be machined like any other ceramic material thanks to diamond tools. Thus Microcertec can realize customized parts made of quartz with various sizes and shapes, high level of precision but without any optical required performances or surface finish. The most important properties of the quartz is its low coefficient of thermal expansion. From an optical point of view, the quartz is generally transparent to the infra-red wavelenghts. Applications Quartz is mainly used for : electrical insulators thermal insulators structural parts Materials From a general point of view, quartz shows : good electrical insulation very small coefficient of thermal expansion good thermal insulation good thermal resistance transparence to the infra-reds vaccum resistance Download Precision machining of quartz (374.69 Ko)

Request for a quote

RIDAT

United Kingdom

Ridat Semi Automatic (SA) Vacuum Forming Machines offer, as standard high specifications, consistent production and a wide range of standard models and readiness to respond to requests for bespoke specifications. Fully automatic moulding processing sequences with manual placement of thermoformable sheet and removal of the vacuum formed product. Key machine features include: Ceramic heaters with multi-zone heater control for balanced heat Power assisted and timer controlled heater box movement Hinged clamp frame - powered by two air cylinders Mould chamber fully sealed to maintain vacuum pressure High capacity vacuum reservoir and pump for instant vacuum supply Microprocessor Controls and HMI Display CE Mark

Request for a quoteResults for

Machinable ceramics - Import exportNumber of results

27 ProductsCompany type

Category

- Ceramics (15)

- Ceramics, industrial (10)

- Ceramics, refractory (3)

- Ceramic manufacturing - machinery and equipment (2)

- Coating machinery (1)

- Diamond tools (1)

- Packing and packaging - machinery and equipment (1)

- Plastic material processing (1)

- Plastic products for the electrical industry (1)

- Polishing equipment and materials (1)

- Precious and semiprecious stones and pearls (1)

- Silicones (1)