- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinable ceramics

Results for

Machinable ceramics - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

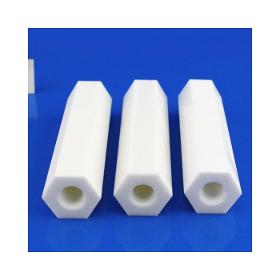

Electrical Insulation Macor Rod: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Rod for Heating Element Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Rod Applications 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Valve Core For Coca-Cola Machine Alumina ceramic valve core for a Coca-Cola machine refers to a component used in the dispensing system of the machine that controls the flow of the beverage. The valve core is a small, cylindrical piece made of ceramic material that is inserted into the machine's dispensing mechanism. The use of ceramic valve cores in Coca-Cola machines is preferred over other materials such as plastic or metal due to their durability and resistance to corrosion. Ceramics is also an excellent material for maintaining the flavor of the beverage as it is non-reactive, meaning it does not absorb any flavors or odors from the beverage. The valve core is responsible for regulating the flow of the beverage through the machine's dispensing system, controlling the amount of liquid dispensed per use. It is an essential component of the machine and should be regularly maintained to ensure optimal performance.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Vacuum metalizing coater for plastic, glass, ceramic, stainless steel, metal etc. The coating experts of your own company. Full set solution for the coating production. We can help you to enter the pvd coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production. Easy to implement. To many people unfamiliar with the process, pvd coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. We developed a turnkey coating process that makes a pvd coating centre easy to implement. A complete coating process consists of several steps: stripping ; pre-treatment; quality control; cleaning & drying; fixturing&visual inspection; pvd coat ;quality control & thickness measurement etc

Request for a quote

PEEKCHINA CO., LTD.

China

Ceramic PEEK Material Discover the art of precision engineering with Ceramic Filled PEEK Rods. Their exceptional machinability enables manufacturers to achieve intricate designs and complex shapes effortlessly. Combined with high strength and good stiffness, these rods ensure your components maintain their integrity, even under demanding conditions. Trust in Ceramic Filled PEEK Rods for reliable performance and seamless machining, elevating your projects to new levels of excellence.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Laser Ceramic Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Laser Ceramic Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina cearmic bar is used when conditions exclude the use of metal, either for chemical reasons or because of excessive temperatures.Their main applications are between 1000 and 1800°C. They may be in directly contact with the medium or may be used as a gas-tight inner sheath to separate the thermocouple from the actual metal protection tube. Ceramic tubes should be mounted in a hanging position above 1200°C to prevent distortion or fracture due to bending stresses. Evenhair-line cracks can lead to contamination of the thermocouple resulting in drift or failure. High purity ceramic strip provide a broad range of engineering properties: High Temperature-Superior Strength-Corrosion Resistance-Thermal & Electrical Insulation along with other specialized characteristics. -Precision Close, Tight Tolerances, -Ceramic Bar & Ceramic Strip machined to customer specifications-Prototype to Production-Intricate ceramic machining -Alumina is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The crucible is produced by depositing pyrolytic boron nitride upon a mandrel having the shape of the desired crucible at a temperature of from about 1850° C. to about 2100° C. until a first layer of boron nitride of suitable thickness has been produced, interrupting the deposition of boron nitride upon the mandrel and lowering the temperature to below 1750° C., and then depositing additional boron nitride upon the mandrel at a temperature of from about 1850° C. to about 2100° C. to produce a second outer layer of boron nitride having a thickness greater than that of the inner layer. Features and Benefits of Boron Nitride ceramic 1. Easily Machinable 2. Exceptional Heat Resistance 3. High Thermal Conductivity 4. Low Thermal Expansion, Excellent Thermal Shock Resistance 5. Outstanding Electrical Insulation - even at high temperatures 6. High wet resistance to molten metals, slags and glass 7. Extreme Corrosion and Wear Resistance

Request for a quoteResults for

Machinable ceramics - Import exportNumber of results

15 ProductsCountries

Company type