- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading system

Results for

Loading system - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quote

ROLLON GMBH

Germany

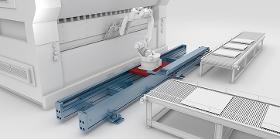

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

The Easyslide is a system of cold drawn steel linear rails with induction hardened raceways. The linear guides consists of an external 'C' profile linear rail and incorporated caged ball bearings. Five rail widths: 22, 28, 35, 43 and 63mm The sliders inside the linear rails ensure an exceptionally compact system System high load capacity Optimal operation even when shocks and vibrations are experienced Multiple standard lengths available depending on the linear rail section (up to 2,000mm). Special lengths are available on request The Easyslide product family includes compact size linear rails with caged ball bearings, fitted with one or more sliders per rail, to ensure high load capacity and long life. If more than one slider is used in the SN series, they can slide independently inside their own cages, or simultaneously in a single cage. The SNK series features rails with hardened and ground raceways. Variable slider strokes and lengths can be selected. All Easyslide linear...

Request for a quote

ROLLON GMBH

Germany

Linear actuators with different guide configurations and drives, available with belt, screw or rack and pinion drives according to different needs in terms of precision and speed. Guides with bearings or ball recirculating systems for different load capacities and critical environments.

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

PAW INDUSTRIAL DOOR SYSTEMS

Turkey

Paw-Pax Isothermal Bellows system is designed to connect the delivery vehicles with the building. With its modern and functional design, Paw-Pax provides maximum impermeability at the loading, unloading sections and shipping points of the facilities. Atmospheric conditions (rain, wind, cold, hot) minimize unwanted air currents in the Paw-Pax door area. With this feature, Paw-Pax isothermal bellows system minimizes problems such as energy loss, lack of hygiene and pollution, undesirable temperature changes that occur during shipment.

Request for a quote

PAW INDUSTRIAL DOOR SYSTEMS

Turkey

Hinged Vertical Ramp systems Manual or motorized loading ramps offer an ergonomic, economical and reliable solution. Hinged Vertical loading ramps, which act as a bridge between your facility and the truck bed, offer ease of use and zero energy cost (in the manual system). Ease of use can be increased to a higher level by adding a motor system to the manual ramp system, optionally.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 125 x 165 cm age 2012 automatic loading system can be used for rear- or front table loading pile height 180 cm Delivery time: immediately from stock Ref: BA180384A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 125 x 165 cm age 2012 automatic loading system can be used for rear- or front table loading pile height 180 cm Delivery time: immediately from stock Ref: BA180385A Please ask for price. We ship and install worldwide!

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8524 precision tension & compression load cell is a versatile sensor for highly accurate load measurements in diverse applications. Optimum measurement quality is achieved with the load cell mounted on a flat, hard and polished contact surface. This requirement does not apply to small measurement ranges of up to 0 ... 2 kN because three knife-edge bearings ensure that the sensor is seated securely. Our brochure „Load Cells“ explains how you can design parasitic loads out of your mechanical system. Through-holes in the outer flange are used for fastening the 8524 sensor to the system structure. The load is applied via the central blind threaded hole or optionally via a load button. Alternatively, a pull plate and even rod end bearings, if desired, can be attached to the sensor for equally easy measurement of purely tensile loads, for instance in Bowden cables or chains. The 8524 sensor is designed to measure static, quasi-static and dynamic compressive and/or tensile loads.

Request for a quote

BIZERBA SE & CO. KG

Germany

Multi point load receptor in extra flat design The simple and robust structure of the electromechanical load receptors guarantees low maintenance and wear-resistant operation with a high level of long-term precision. The load receptors of the iL Professional F/MP series can be optionally used: built-in or freestanding, s/s lacquered deep black or made of s/s. Perfectly suitable for many applications. Despite the large number of options that the modular component system affords, all load carriers are available as standard products.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Available in different sizes and for film webs from 310 mm to 610 mm. Optionally with roller knife cut for soft blisters or die-cutting tool for hard blisters. Additional equipment options for online printing, vacuum, MAP, automatic loading system and much more.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 137 cm age 2008 computer control with monitor touch screen colour screen air table metallized 2 side tables (metallized) Transomat TR 150 BL 3 - automatic loading system rear table loading Transomat TR 130-ER 4 handling from left to the right power supply 3 x 220 volts / 50 cycles Delivery time: shortly Ref: PO240103A Please ask for price. We ship and install worldwide!

Request for a quote

GSW SCHWABE AG

Germany

ideally suited for large coil widths and thicknesses dual arbors for minimal deflection hydraulic wedge type expansion systems highestquality Reel Arbor with maintenancefree bearing and minimal deflection integrated hydraulically powered coil loading system for narrower coils even onesided use possible coil reels as seperate movable components proven support of large rollforming applications especially for the manufacture of welded tubes SHZR Series with variable speed drives via threephase motors and frequency inverter

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

To be installed at the exit of the packaging machines and welding machines. ROTATING TABLE OF ACCUMULATION WITH STAINLESS STEEL STRUCTURE AND NYLON PLAN The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The rotating tables with nylon plan are available with a diameter of 800, 1200 or 1400 mm, and are suitable for bottles, cans and products that can overturn in the concave or convex turntables. The flat rotating tables can be equipped with loading systems and automatic unloading and thus be used as "accumulation areas" between an automatic machine and another. Edges and sides nylon version Flat turntable with holding sides, polyethylene plan, useful height of 810 mm and a mechanical speed variator.

Request for a quote

FERPLAST SNC

Italy

ACCUMULATION ROTATING TABLE IN STAINLESS STEEL AISI 304 The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The stainless tables are available with rotating table diameter from mm. 800 to 1400 mm and exist in concave or convex version (ideal for bags and products that are accumulated) and flat (ideal for bottles, cans and products that can spill). The tables are supplied with adjustable feet up to 40 mm. On request it is possible to have wheels with brakes. Edges and sides stainless steel version The flat stainless steel version is equipped with containment rod while the concave tables do not have containment systems as the products accumulate in the center. The models in flat version can be equipped with double-rod containment, closed side with height 50 cm, exit slide, load system for incoming products

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The preferred field of application for the (gas) hydraulic industrial buffer (COMPENSER®) of the S-series is in the medium to heavy engineering industry sector. As a heavy duty shock absorber it is used in large crane systems (e.g. harbour crane, shipyard crane or container crane), metallurgical plants, rolling mills, loading systems or as end stop integrated in a rail buffer stop. Design & Function: The gas-filled inner tube 2 enters the outer tube 9. The damping medium flows from the pressure chamber 6 through the throttle orifices 8 of the metering tube 7 into the volume balance chamber 5. The separating piston 4 simultaneously moves in the direction of the impact cap 1 and compresses the nitrogen gas filling. In the gas space 3, the energy is stored which is required for the reset of the inner tube. When the inner tube 2 returns to the initial position, the separating piston 4 moves in the opposite direction and presses the damping medium back into the pressure chamber 6.

Request for a quote

NORELEM FRANCE

France

The slot nut is twisted into the profile slot and so can be subsequently inserted into existing systems. The spring-loaded ball allows the nut to be fixated anywhere in the profile slot.

Request for a quote

SAMSYS GMBH

Germany

The Mini Shaft Loader allows you to load short shafts. The loading is done automatically. Do you have remnants of long bar feeder and would you like to process them? Or do you want to load very short shafts automatically? The MSL is the ideal complement for the Multi-3000 to load short shafts. It has a multi-profile loading prism. So you can load round and hexagonal material and all this without changing channels. Special profiles are possible on request. Impact-free recharging thanks to the exclusive recharging cycle. The recharging cycle is based on the patented recharging mechanism of the Multi 3000. After fast and precise bar removal, the material is gently placed on the loading prism. The Mini Shaft Loader is connected to the bar feeder. This takes over the power supply and control of the loading system. The material is fed via the slide of the loading magazine.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Ideal automation solutions for loading and unloading of parts on machining centres, presses, measuring stations, etc… Convenient, accurate, repeatable and reliable! The CLA Robot Cell is composed of the following: - A polyarticulated robot or scara with specific grippers - A camera device for part recognition - Automatic camera calibration - Parts loading/unloading system - Protection (cage, mats, detection, etc) - Each application is studied and simulated in order to define the ideal solution - Microplates screening. CLA is a center of expertise of Mitsubishi robots

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Muscular and skeletal problems are the most common reasons for people being unable to work, particularly if they have a job that frequently involves physically strenuous activity like pushing and pulling loads. The electric drive systems of the Blickle ErgoMove® series reduce these health risks considerably. The effort required for pulling and pushing is reduced by up to 100 %. The physical strain on the operator is decreased during internal material transport due to the considerably lower amount of effort required compared with manual operation. Equipment and transport units of any kind can be quickly and easily upgraded with a “plug & play” electric drive, steering and braking assistance. The modular sets include two fixed castors with electric drive, cockpit solutions with integrated controls and battery unit as well as all relevant safety features.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

TRAPO GMBH

Germany

4- or 6-axis jointed-arm robots of various well-known brands are acting highly flexible. The high-speed systems palletize, sort, load and commission fast and high-precision single pieces, rows, partial layers or complete layers. - Low space requirement - Flexible use for various applications - Product and industry independent: Mature gripper technologies transport a wide variety of goods - Suitable for different packages and load carriers - Set on rails, the jointed-arm robot moves to different palletizing positions - Application-oriented, flexible combination of the optimally complementary technical properties of high-speed palletisers and robots

Request for a quote

EC PLAZA

South Korea

1. Foam Filled Fender Foam-filled fenders are constructed with an energy-absorbing foam core and a tough outer skin of filament-reinforced polyurea elastomer. 2. Fender Skin The elastomer used in the fender skin is polyurea. The skin is reinforced by filament winding wrap in a helical and hoop direction, which is controlled by an automatic winding system with load cell sensors at each filament. Our four-axis filament winding system, also used to build spacecraft fuel tanks, takes control and positions each filament for maximum strength and even finish. The polyurea shows far superior physical properties to those of the rubber. The durable and resilient polyurea skin also offers the best resistance to salt water and ultraviolet light. 3. Various colors Standard color shall be made of Dark red, gray and black. But customers can request yellow etc.

Request for a quoteResults for

Loading system - Import exportNumber of results

148 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (6)

- Internal transport systems (5)

- Weighing and dosing equipment (5)

- Conveyor belts (4)

- Goods handling systems, continuous (4)

- Bird cages and aviaries (3)

- Finishing and binding - machinery and equipment (3)

- Packing and packaging - machinery and equipment (3)

- Shelving, storage (3)

- Automation - systems and equipment (2)

- Components and parts for small household appliances (2)

- Doors, industrial (2)

- Engines & Parts (2)

- Gears (2)

- Handling - Machines & Equipment (2)

- Import-export - oil (2)

- Magnets (2)

- Metal straightening machines (2)

- Metals - Machines & Equipment (2)

- Metalworking - portable power tools (2)