- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- temperature

Results for

Temperature - Import export

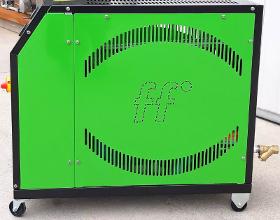

FRIGOFLUID S.R.L.

Italy

Most industrial process temperature control units work through the pressure exerted on the water of the process utilities: this is convenient in most “standard” cases, given the higher efficiency developed by the system. However, some critical process issues can make this type of operation difficult: this is the case of machines that leak fluids, or with leakage, and that it is not convenient to maintain on the spot. In such cases, it is therefore useful to work with a vacuum temperature control unit, which sucks in utility water. FTT PD water thermoregulators are flexible and effective systems, which can work under either pressure or vacuum depending on the peculiarities of the system. Any fluid losses are therefore minimized during operations. A simplicity of operation is also ensured by the touch-screen panel, also found on other Frigofluid temperature controllers. Models with an increased pump are also available for users characterized by high pressure drops.

Request for a quote

FERPLAST SNC

Italy

ME-ASD SERIES with 10 mm DOUBLE SEALING BAR BY IMPULSE WITH TEMPERATURE CONTROL Semiautomatic bench sealing machine with electric pedal and double impulse sealing bar with temperature control, (an electronic circuit prevents overheating and allows continuous operation), suitable for closing polyethylene, polypropylene, PVC, aluminum coupled bags, etc. The sealing bars are closed by means of an electromagnet with foot control. Timers for sealing and cooling control ensure maximum reliability on all types of material. The "cold closing" time allows the bars to remain closed for a time set by the operator and apply a pressure that reinforces the sealing. The ME ASD series sealers can in some cases be used for sealing advertising banners and creating pockets for fixing them.

Request for a quote

FERPLAST SNC

Italy

This gluing machine for professional use permits the application of granulated or stick (diameter 43 mm) hot melt adhesives. Suitable for bonding large surfaces. The fusion system in the closed tank allows a large amount of melt adhesive in few second for fast delivery. The temperature is electronically controlled by the LCD, which guarantees a specific precision and ease of use. Thanks to the melting tank (optional) you can heat the glue prior to use by making use of the gluing faster and cheaper. Available models: FPTR 55 LCD: electro-pneumatic gluing machine with adjustable temperature from 50 to 210° C FPTR 55 LCD HT: electro-pneumatic gluing machine with adjustable temperature from 50 to 250° C

Request for a quote

FERPLAST SNC

Italy

Spray gluing machine for professional use, it allows the application of hot melt adhesives in granules or stick diameter 43 mm. Thanks to special nozzle nebulizes the glue and does not create thickness. Suitable for the bonding of large surfaces. The closed fusion system container allows to have in a few seconds a large amount of molten adhesive to a fast dispensing. The temperature is electronically controlled by an LCD display, which guarantees a particular precision and ease of use. With the melting tank (optional) you can heat the glue before use, making the use of the gluing machine faster and cheaper.

Request for a quote

FERPLAST SNC

Italy

New model for professional use with use of hot melt adhesives granulated or stick diam. 43 mm. and manual advancement (there is no need compressed air). The fusion system in closed tank allows to have in a few seconds a large amount of molten adhesive to a fast dispensing. The temperature is regulated by thermostat at bimetal strip, which ensures a particular strength and wear resistance. It also has a magnetic base that allows you to place it on metal surfaces. Available models: MS 200-TER: model with temperature regulation with thermostat MS 200-LCD: model with temperature adjustment by LCD display

Request for a quote

FERPLAST SNC

Italy

MS80 - MANUAL GLUE GUN WITH GRANULAR HOT MELTS The MS 80 glue gun works with granular hot melts without compressed air. Simply connect them to the socket – ready. Use the thermostatic controls to set the requested temperature between 20°C and 200°C and you always work with the optimum glue temperature. Pull the trigger to apply the melted granulate. The MS 80 has proven successful in practice over a long period of time.

Request for a quote

FERPLAST SNC

Italy

This gluing gun for professional use enabling the application of hot melt adhesives in pellet or stick diameter 43 mm .. Suitable for bonding small and large surfaces. The fusion system in the closed tank allows to have in a few seconds a large amount of melt adhesive for a fast delivery. The temperature is regulated by a thermostat at bimetallic strip, which guarantees a particular strength and wear resistance. Thanks to the melting tank (optional) you can heat the glue prior to use by making use of the gluing faster and cheaper. The gluing is provided with standard nozzle # 3074. Other nozzles available on reservation.

Request for a quote

FERPLAST SNC

Italy

CF SERIES - CONSTANT TEMPERATURE HEAT SEALERS WITH PEDESTAL AND FOOT PEDAL ( for multi-layer bags) THE CF SERIES of constant heat sealers with pedestal and operated by foot pedal, are ideal for sealing bags made of compunds, multi-layer films, co-extruded films, OPP, heat-sealable cellophane. It is not suitable for polyethylene films. Being operated by foot pedal, the hands are free to feed the machine. The sealing jaws of the type "hot bar" are equipped with resistance and temperature controller for controlling the temperature from 30 ° C to 200 ° C. The temperature of the sealing jaws is adjustable according to the type and thickness of the material to be sealed, and is kept constant by a heat thermo-regulator. The maximum sealable thickness, that always varies according to the type of sealable material, is 0.25 mm. (50 mm. total). Also available in CFN version with timer and acoustic signal at the end of sealing.

Request for a quote

FERPLAST SNC

Italy

Digital and semiautomatic bench sealer, with electric pedal and sealing bars at constant temperature, for closing polypropylene bags and laminated / laminated aluminum, paper, barrier materials, etc. The "hot bar" type sealing bars are equipped with resistance and electronic thermoregulator. Thanks to the new latest generation electronic control card, all controls, adjustments and alarms are more easily set. The digital control of temperature, time and pause interval, it is more precise and functional, thanks to the new control panel, and to the large 1-line by 16-character alphanumeric LCD display. Temperature adjustment 0-150 ° C, with alarm of ± 5 ° C with respect to the set temperature. The closing of the bars takes place by means of an oversized electromagnet which guarantees a high sealing pressure and allows the sealing of high thickness envelopes with or without side gussets. For a higher production it is sufficient to select the automatic cycle with timed closing.

Request for a quote

FERPLAST SNC

Italy

MANUAL LEVER SEALER WITH CONSTANT TEMPERATURE Thermosealing machine that works with sealing bars at a constant temperature for the closure of polypropylene bags and coupled/aluminum laminate, paper, barrier materials, etc. The sealing bars of the type "hot bar" are equipped with resistance and controller for controlling the temperature from 30 °C to 200 °C. The closing of the bars is through a quick manual lever that guarantees a high sealing pressure and allows the sealing of envelopes high thickness with or without side gusset. Attention: it is necessary to preheat for about 5 minutes. The sealer is available in two models: ME 300 CFH BZ with checkered knurled bars ME 300 CFH BL with longitudinally knurled bars

Request for a quote

FRIGOFLUID S.R.L.

Italy

Often the main critical issue for molding industries is not achieving the temperatures needed for their processes, but maintaining them over time. Hence the usefulness of temperature control units that not only send the fluids needed to do the job up to temperature, but are capable of subsequent self-tuning. This is the way FTT DC water temperature controllers operate, which wrap direct cooling to stabilize fluid grades after the desired temperature has been reached. This requires integration with a source of cooled water: a simple well or a chiller or cooling system (chiller or dry cooler). Our engineers are available to determine which cooling solution is the most effective and economical. Not only that. The management of these successive heating-cooling steps is easier when done with a touch screen: a feature with which FTT DC temperature controllers are equipped. Units in the FTT category are specially designed to condition molds.

Request for a quote

FRIGOFLUID S.R.L.

Italy

FT water temperature controllers make it possible not only to cut down on the use of electrical power for heating (in fact, the heating elements remain off during steady-state operation), but they also make it possible to limit the cooling power spent on cooling by self-stabilizing through a process called Autotuning. This system also saves resources (water and energy) compared to units without them. They are designed to condition molds and cylinders for various industrial processes, including plastics and rubber molding and extrusion, and in the paper industry.

Request for a quote

MITA COOLING TECHNOLOGIES

Italy

MITA offers different configurations of air-cooled or water-cooled industrial process chillers: all equipped with electronic microprocessor for setting and displaying the outlet liquid temperatures and all suitable for Industry 4.0. Some advantages of industrial process chillers. - Autonomous unit, with air condensation. - Maximum reliability and performance proven by strict internal tests. - Customizations and flexibility Up to 80% of energy savings in the versions with free cooling system.

Request for a quote

DRAGFLOW SRL

Italy

Submersible pumps with agitator for charged and abrasive mixtures Main features Pump provided of agitator to stir things up High abrasion resistance Low rotation speed Able to handle up to 70% per weight material density Accessories: High depth kit Algae cutting blade Humidity and temperature sensor Jet Ring system Electric pumps are available in 50Hz and 60Hz versions.

Request for a quote

DRAGFLOW SRL

Italy

Submersible pumps with agitator for charged and abrasive mixtures Main features Pump provided of agitator to stir things up High abrasion resistance Low rotation speed Able to handle up to 70% per weight material density Possibility of installation on mechanical arm Dredging systems (side excavators or dredging head) available on request Accessories: High depth kit Algae cutting blade Humidity and temperature sensor Jet Ring system

Request for a quote

DC DI CANDIA RUOTE

Italy

The XTW series is the only wheel which is assuring a temperature resistance up to +400°C and not being made out of aluminum or cast-iron, with the big advantage to preserve the floor and to secure a dramatic reduction of noise if compared to metal wheels.They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement. The XTW wheels can be fitted into a specific series of brackets for high/low temperatures, which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted in the world of uses in temperatures and bakery / food industry. Brackets are fully certified and manufactured with food and sanitary grade Stainless Steel in AISI 304 / 316, and are available in both metric and inches standard sizes, and are also available in double-layer galvanized pressed steel. They are RoHS - REACh compliant.

Request for a quote

DC DI CANDIA RUOTE

Italy

The LTW series wheels are manufactured in high grade Polyamide and filled with glass fibers plus additional natural fibers, and molded through a new vaacum and material drying process to assure high resistance in temperatures bewteen -40°C and +150°C. They are available with plain bore and with HQS self lubricating bushes, to allow a good rolling capacity in any condition of use. The LTW wheels can be fitted into a specific series of brackets for high/low temperatures, which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted in the world of uses in temperatures and bakery / food industry. Brackets are fully certified and manufactured with food and sanitary grade Stainless Steel in AISI 304 / 316, and are available in both metric and inches standard sizes, and are also available in double-layer galvanized pressed steel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DC DI CANDIA RUOTE

Italy

The wheel core of the RHT series is manufactured in special Ditherm® compound, combined with special fibers and molded under an innovative DC developed high pressure + extreme temperature process, and its tyre is made in a special high quality elastic rubber for high temperatures. The black rubber tyre is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or vulcanization such as for almost any competition product. This particular bonding is resulting in the highest quality wheel in its range of application, featuring a drastic reduction in the risk of tyre de-bonding during the work in temperatures. They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement.The RHT wheels can be fitted into a specific series of brackets for high/low temperatures.

Request for a quote

DC DI CANDIA RUOTE

Italy

The MTW series has replaced the old “phenolic” wheels, and is manufactured in special Ditherm® compound, combined with special fibers and molded under an innovative DC developed high pressure + extreme temperature process which results in the highest quality wheel in its range of application. They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement. The MTW wheels can be fitted into a specific series of brackets for high/low temperatures, which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted in the world of uses in temperatures and bakery / food industry. Brackets are fully certified and manufactured with food and sanitary grade Stainless Steel in AISI 304, and are available in both metric and inches standard sizes, also available in double-layer galvanized steel.

Request for a quote

FDM - ENVIRONMENT MAKERS

Italy

Temperature from -25°C up to +70°C Configuration Volumes from 25 up to 2300 liters stillFACE Stability test performing controller revoFACE Dynamic performing programmer Shelves Included and variable in quantity according to the model Ventilation Forced ventilation fan Alarms High/Low temperature and humidity Electric Power 220-240V ~ /50 Hz different power available 100% Customizable solution

Request for a quote

FDM - ENVIRONMENT MAKERS

Italy

Temperature from -25°C up to +70°C Humidity from 10% up to 98% Configuration Volumes from 25 liters up to 2300 liters stillFACE Stability test performing controller revoFACE Dynamic performing programmer Ventilation Forced ventilation fan Rack 1* Height-adjustable Alarms High/Low temperature and humidity Electric Power 220-240V ~ /50 Hz different power available 100% customizable solution

Request for a quote

FDM - ENVIRONMENT MAKERS

Italy

Temperature from -40°C up to +180°C Humidity from 10% up to 98% Illumination Dimmable illumination with optional lamps Configuration Volumes from 25 up to 1500 liters stillFACE Stability test performing controller revoFACE Dynamic performing programmer Shelves Included and variable in quantity according to the model Ventilation Forced ventilation fan Alarms High/Low temperature and humidity Electric Power 220-240V ~ /50 Hz different power available 100% customizable solution

Request for a quote

E.T.I. S.R.L.

Italy

These temperature gauges are designed for use in chemical, petrolchemical processing industries. They are built to resist the most severe operating conditions created by the ambient environment and the process medium. An TIG welded case/bulb strengthens the whole construction. A leak tight fit is ensured if the instrument is filled with a dampening fluid to prevent damage due to vibration.

Request for a quoteResults for

Temperature - Import exportNumber of results

24 ProductsCountries

Category

- Applicators for adhesives and glues (5)

- Wheels, castors and rollers (4)

- Package sealing machinery (4)

- Measurement and regulation equipment and instruments - temperature (3)

- Testing equipment (3)

- Pumps (2)

- Bakery - machinery and equipment (2)

- Temperature sensing devices (1)

- Refrigeration plants and equipment, commercial and industrial (1)

- Bakery - machinery and equipment (1)