- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tapping machines

Results for

Tapping machines - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Self-tapping insert installation tool for all types of self-tapping threaded inserts (with cutting slots Ensat 302, with cutting holes Ensat 307 and Ensat 308) and in different materials (galvanized steel, stainless steel, brass, plastic) For machine use Depth of grip adjustable with bushing Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for metric thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

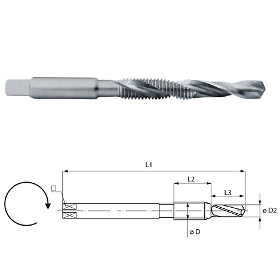

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

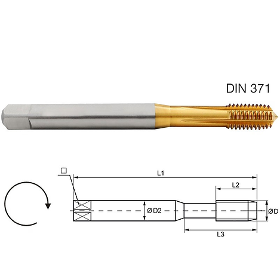

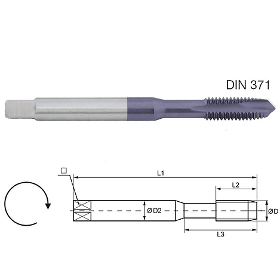

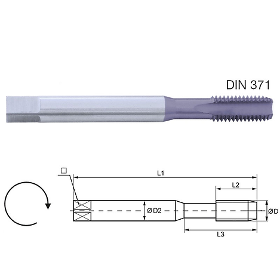

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: Oversized diameter 6GX Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6GX Tolerance ISO3/6GX – Thread with large clearance. The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

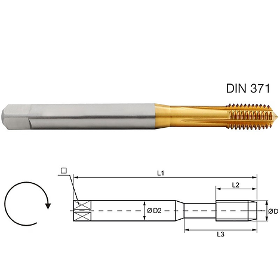

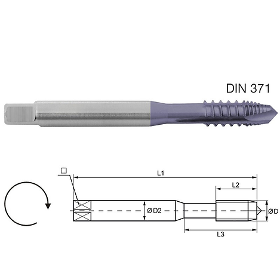

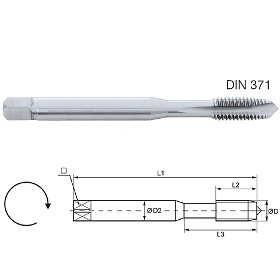

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: General use Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6HX The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

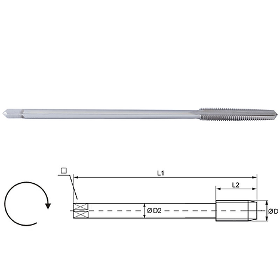

Thread standard: Metric, ISO DIN 13 Type: Machine nut tap Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 850 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Maschine Nut tap for through holes with long shank for taking some thread cutted nuts. For thread depth up to 1,0 times diameter. Also useable for thread cutting in awkward places. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

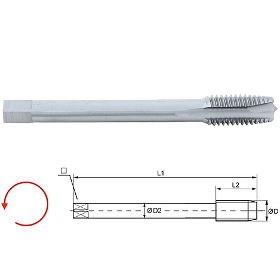

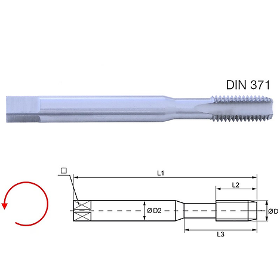

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

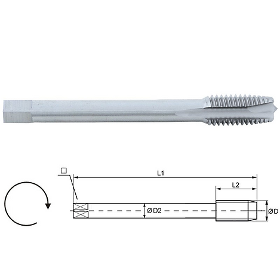

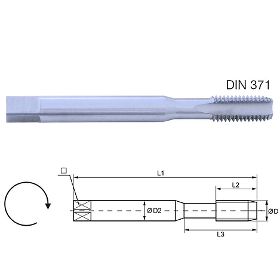

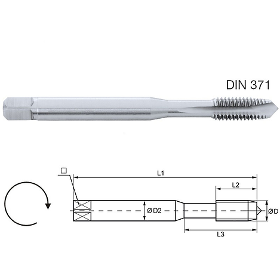

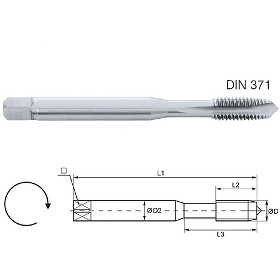

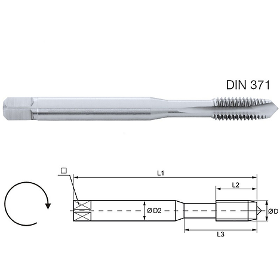

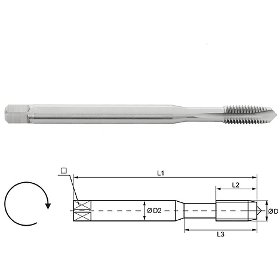

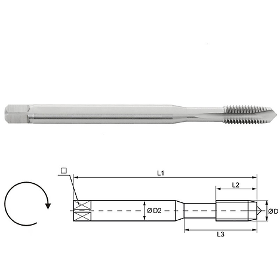

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materialsCorrect lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants. Brand: Baer Tools (Germany)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For brass Material of product: HSSE Surface treatment: TIN For materials: Brass (short chipping) Tensile strength up to: 600 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Due the cutting geometry specially recommended for applications in Copper-zinc alloy (Brass) - short-chipping. Tap for machine use in blind and through holes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Undersized diameter 4H Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO1/4H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Fine Tolerance 4H (ISO1) for close fit bolt connection. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Oversized diameter 6H+0.1mm Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H+0.1mm Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. + 0,1 mm oversize for electroplating allowance ≈ 25 µm thickness. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Oversized diameter 7G Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/7G Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Tolerance 7G – allowance for distortion caused by heat treatment. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants. We also have holding tools for taps and dies

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Oversized diameter 6G Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6G Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Tolerance ISO3/6G – Thread with large clearance. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=150 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=150 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=120 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=120 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Overlengthed (long shank) L=100 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Overlengthed (long shank), L=100 Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

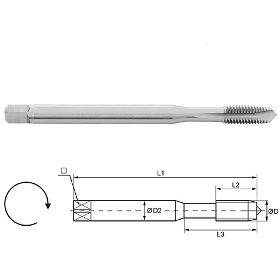

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quoteResults for

Tapping machines - Import exportNumber of results

63 ProductsCompany type

Category