- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper alloys

Results for

Copper alloys - Import export

M.E.G.A. SPA

Italy

M.E.G.A. S.p.A. has always stood out for its multitechnological capabilities and highperformance manufacturing, efficiently and flexibly carrying out the entire production cycle of each fitting, starting from forging through to the final testing phase and any relevant certifications. STANDARD FITTINGS and UNIONS are high quality products that can be supplied both threaded (according to ASME B1.20.1) and socketweld, as well as SWAGE NIPPLES that are available in all standardised variants threaded, BW, plainend, eccentric. This family of standard products is available in carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and others. The material can be certified NSF 61, NACE, PED, and Norsok.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

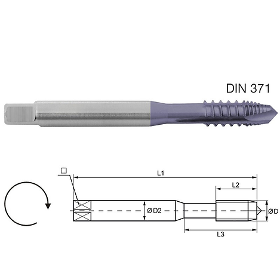

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For stainless steel Material of product: HSSE Surface treatment: VAP For materials: Stainless steels, Copper alloys and copper-zinc alloys etc* Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry and surface treatment for Stainless steel. The oxide surface (vaporized) improves the adhesion of the cutting oil and provides a stabil lubricant film. Cold welding in the tap flanks is reduced. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: Stainless Steels, Inoxable Steels, V2A (AISI 304), V4A (AISI 316), Steels up to 900 N/mm² Copper alloys and copper-zinc alloys (long-chipping) Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

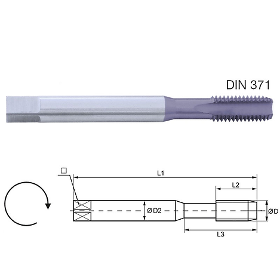

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

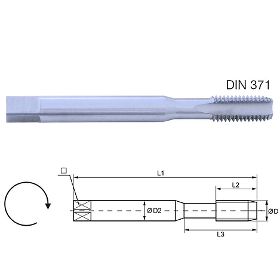

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

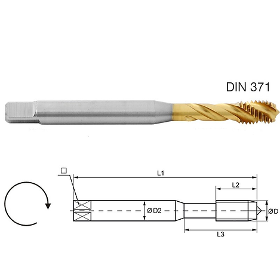

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For brass Material of product: HSSE Surface treatment: TIN For materials: Brass (short chipping) Tensile strength up to: 600 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Due the cutting geometry specially recommended for applications in Copper-zinc alloy (Brass) - short-chipping. Tap for machine use in blind and through holes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

Materials: Body: Copper-Nickel alloy, with 80% of Copper and 20% of Nickel - ISO429 Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quote

M.E.G.A. SPA

Italy

The SPECIAL PRODUCTS section includes all FITTINGS, NOZZLES and SPECIAL FLANGES made to specific customer requirements in the following materials carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and other metals. HEAVY WALL FITTINGS are manufactured from customer specifications, or from accurate design according to the requirements of international codes, including ASME B31.1, B31.3, B31.4, B31.8, ASME B&PV Code Section I, Section III, Section VIII Division 1 and Division 2, PED, RCCM, EN 13480, EN 10253 or others, and is supported by finite element analysis or calculation reports. In this product category, we have special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements.

Request for a quoteResults for

Copper alloys - Import exportNumber of results

12 ProductsCompany type