- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- increasing hardness

Results for

Increasing hardness - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

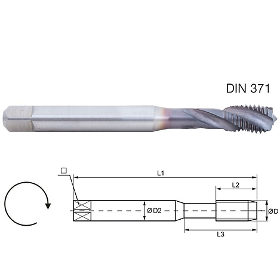

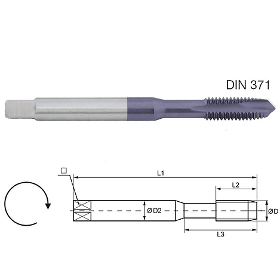

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

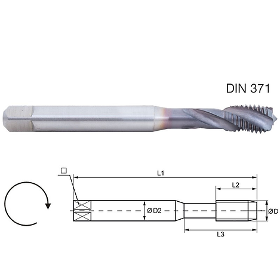

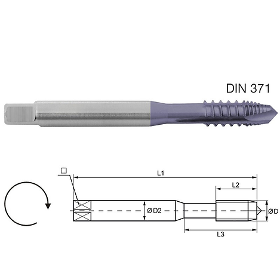

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

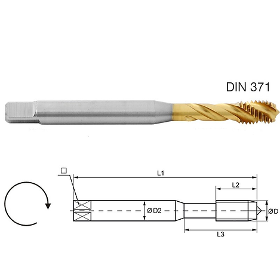

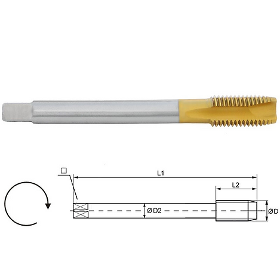

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

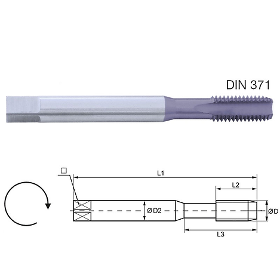

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quoteResults for

Increasing hardness - Import exportNumber of results

12 ProductsCountries

Company type

Category