- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- increasing hardness

Results for

Increasing hardness - Import export

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

Calcium Formate 98% is used as an animal feed preservative. It acidifies the feed and by doing so, it prevents the growth of microbes and increases the shelf life of the feed. It prevents the growth of bacteria and fungi. It is used as a masking agent in chrome tanning of leather because it enhances the efficiency of leather penetration of the chrome. Calcium Formate is also used as a replacement of formic acid for the pickling process. It is also used as a grout and cement additive. It adds desirable properties to the final products. It helps increase hardness and decrease the setting time. It prevents the corrosion of metal substrates within cement or grout. It very effectively prevents efflorescence. Calcium Formate functions as a fire retardant in drywall. Its mixtures with urea are very effective deicers. These cause less corrosion of steel and cement surfaces.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our experts continually innovate and optimize our range of abrasives, making Tyrolit a trusted partner in the automotive industry and other sectors requiring precise gear grinding. We offer a comprehensive assortment of grinding wheels, cup wheels, and worm grinding wheels for generating, bevel gear, and profile grinding. Generating gear grinding uses a worm grinding wheel to continuously grind the desired profile into the workpiece. Unlike this, profile gear grinding machines each gear tooth individually, suitable for large gears. Tyrolit's vitrified-bonded profile grinding wheels have set industry standards, delivering exceptional cost-efficiency, process stability, and finish quality for gears of all sizes. With increased quality requirements, hard-fine machining of gears is essential. Tyrolit's special cup wheel line for bevel gears ensures exact topographies and pitches, offering high productivity, low thermal load, and maximum profile retention.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our files, bench stones, knife blade files and hollow chisel stones are available in different grit sizes from coarse to super fine depending on the desired application. Due to the large selection of different tools, the portfolio covers a wide variety of applications. The various files and stones can be used for machining tools in the woodworking and machine industries as well as for whetting knife blades. Tyrolit combination stones consist of two different grit sizes, allowing a wide variety of workpieces to be deburred. For improved ergonomics, certain products are equipped with handles to increase working comfort and make hard-to-reach places effortless to machine. One tool that no workshop should miss is the TYFIX hand rubbing brick, which allows you to effortlessly remove dirt, rust and paint from various surfaces. Tyrolit's tools are designed for different materials - from vitrified-bonded tools to resin- and electroplated diamond files for HSS and tungsten carbide.

Request for a quote

RONIX GMBH

Germany

How many times have you had problem fastening hart-to-reach bolts and nuts? No need to worry about them anymore. Ronix Ronix Extension Bar 25cm is in the market to help you fasten all sizes of bolts and nuts in any position. Ronix Extension Bar 25cm is just what you need to carry along with your socket set in order to be able to deal with all kinds of bolts and nuts. Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

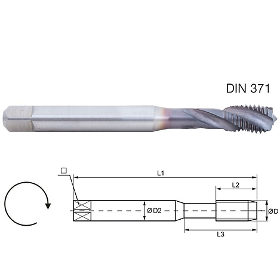

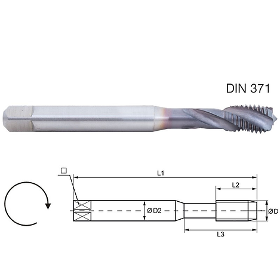

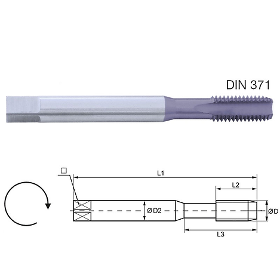

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

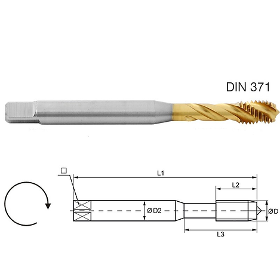

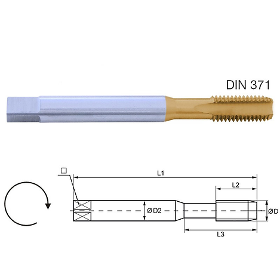

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

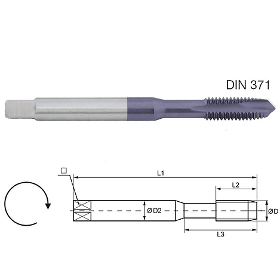

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: General use (long-life version) Material of product: HSSE Surface treatment: TIN For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

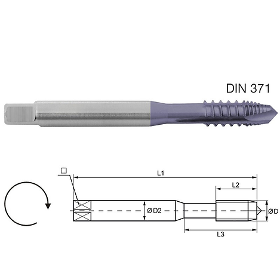

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For aluminium Material of product: HSSE Surface treatment: TiAlN For materials: Pure Aluminium, Aluminium cast and wrought alloys, Soft iron etc* Tensile strength up to: 700 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for light alloys (Aluminium, Copper, etc). The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Soft Iron Pure Aluminium, Aluminium cast and wrought alloys Si<5% (long-chipping) Pure Copper, Copper alloys and copper-zinc alloys (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RONIX GMBH

Germany

Ronix uses the best and highest-quality raw material in manufacturing hand tools. these extension bars are made of superior chrome-vanadium material to increase torque and unique hardness. This high-strength chrome vanadium steel extensions provide high torque for greater turning power. This extension bars are equipped with 3-layer chrome coating which protect the tool from corrosion and rusting. these extension bars are designed remain locked onto the drive until you push the quick-release disengage button.

Request for a quote

VIRMER

Netherlands

Lens D20 F50.8 is installed inside the laser head of the machine with a seat size (diameter) of 20 mm. Chamfered edges eliminate the risk of scratches and chips during installation. The average focal length of the lens is 2 inches, which allows processing non-metallic materials with high detail. Focus lenses made of zinc selenide. These are lenses of high quality and increased hardness. It require careful and careful handling, special measures during installation, replacement and operation.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Spinodal materials are custom-engineered for safety hand tools that are non-sparking, non-magnetic and highly corrosion resistant. They benefit from age hardening techniques that further increase their strength and hardness for high performance safety tools. Alloys AM 388™ (UNS C72650) is a copper based Spinodal alloy that offers non-sparking, non-magnetic and high strength properties. AM 388™ is accepted as a safe replacement material for Beryllium Copper alloy. Safety Tool Applications Engineered for an array of hand-held non-sparking safety tools including: Corrosion resistant wrenches Hammers, axes and picks Corrosion resistant screwdrivers, pliers and spatulas

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our Spinodal strip materials in Copper-Nickel-Tin alloys offer high ductility for forming into shaped charge liner material for the perforation of oil and gas well liners. Shaped Charge Liner Material Advantages The Spinodal material is produced through our wrought powder compaction process which imparts properties allowing the material to virtually ‘disappear’ upon activating the charge. The material is well suited to “big hole” applications for perforating charges and leaves little residue (commonly referred to as ‘carrots’ or ‘slugs’). Pfinodal® (C72900) and AM-388™ (UNS C72650) We produce two spinodal alloys for these shaped charge applications - Pfinodal® (C72900) copper alloy and AM-388™ (UNS C72650). They benefit from age hardening techniques that further increase their strength and hardness required for deep hole penetration applications. These spinodal materials deliver superior mechanical and physical properties in comparison

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Materials used in Mining and Drilling are subject to some of the harshest environmental conditions in the world. We’re committed to manufacturing durable, high strength and corrosion resistant Spinodal products for vital drilling and downhole components. Unrivaled Resistance to The Harshest Environments Our Spinodal alloys are highly specialized and possess excellent corrosion resistance. They benefit from age hardening techniques that further increase their strength and hardness while offering superior mechanical and physical properties for demanding applications including: Pfinodal® (C72900) Drill Bit Material for Bearing Components such as Sleeves, Bushings, Washers and Caps Pfinodal® (C72900) and AM-388™ (UNS C72650) Shaped Charge Liner Material for Wall Perforation Pfinodal ® (C72900) Bar and Tube for Downhole Housings, Centralizers, Joints

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

SpeedCore is a newly developed substrate for hobs. The increased hot hardness of the intermetallic cutting material allows for cutting speeds of at least 30 % higher compared with HSSPM4/ 14 hobs, resulting in shorter production times without sacrificing tool live and ocmplies with the demand of customers for easy handling and easier recycling. Combining the new SpeedCore substrate with a custom coating achieves top performance with easy implementation and high reliability. Advantages - Improved productivity of up to 70 % - Process reliability (like HSS-PM) - Easy to implement; also on older or unstable machines - Regrinding and coating possible without problems

Request for a quote

SANHA GMBH & CO. KG

Germany

Threaded brass fittings (material no. CW617N, composition CuZn40Pb2) are well-suited for the use in a wide range of applications such as heating, rain water or water /glycole mixtures (or similar water with frost protection additives). Threaded brass fittings are durable and easy to install and have a high Brinell hardness for increased corrosion protection. Our programme of threaded brass fittings also includes brass extensions. The wide range of different threaded brass fitting dimensions from ¼“ up to 2 1/2“ as well as several different chromed versions off installers the option of finding the right fitting for the application in question. Even though brass fittings are allowed for drinking water installations in many countries, we recommend the use of our lead-free series for this application.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

ELITE roller chains with sawtooth plates are extremely wearresistant and designed for optimum fatigue strength. They are used mainly in the wood processing industry for transporting raw timber and sawn planks. ELITE highlights: • Our chains are based on the minimum requirements set out in standard ISO 606. • The steel alloys used are case-hardened and tempered. • Heat treatment of all chain parts is optimized to suit size and application • All roller chains are prestretched to >40% of breaking load as standard • The high quality assurance standard fulfils the requirements of ISO 9001 • Plates 1 are shot-blasted for maximum fatigue strength • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights: • Wide range of products • Dimensions according to ISO 1275 • Versions with small rollers and transport rollers available • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high Product range: • Double pitch roller chains ISO 1275 • Double pitch roller chains with straight plates ISO 1275 • Double pitch hollow pin bushed chains • Double pitch hollow pin roller chains contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

Softcontrol Data offers individual setting options and a clear presentation of the information on the display. The device is a comprehensive alarm system for upstream water softening systems with high safety requirements for the soft water quality. The limit values for the water hardness can be set in the range from 1 ppm to 18 ppm based on the input water hardness. The measurement data and service messages are automatically saved in the readable, integrated USB stick and transmitted via a current loop and LAN interface with MODBUS / TCP. For increased operational and process reliability with the best user friendliness. A continuous measurement takes place approx. 2 times per minute as long as water is flowing. indicators are not used and an ion-selective sensor is used instead. This monitors itself and indicates the required exchange itself. This is usually the only maintenance on the device that has to be carried out around twice a year.

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

Softcontrol RM monitors the soft water produced by the softener for increased hardness concentrations and also triggers the regeneration of the softener in terms of quality. The monitoring of variable water hardness limit values from 1 ppm to 18 ppm takes place as well as the quality-controlled triggering of the regeneration of two columns of the softener. A continuous measurement takes place as long as water flows. Indicators are dispensed with and low-maintenance ion-selective sensors are used instead. The device has self-monitoring so that, in the event of service, information is provided automatically for less maintenance. The measured values are output on the display, via a 4 to 20 mA current loop and via a LAN data interface with Modbus / TCP. The data is also saved in the electronic operating log (USB stick). Installation and parameterization is easy to carry out on the device.

Request for a quote

PET TECHNOLOGIES

Austria

We manufacture blow molds for PET blow molding machines of our own production as well as for linear and rotary equipment of other manufactures. For the high quality blow molds we use: - full range of processing equipment to produce blow molds of any complexity for all types of blow molding machines; - only certified raw materials: blow mold is made of special German duraluminium homogenized alloys with unique mechanical properties; - electrochemical molds surface coating to increase corrosion resistance, surface hardness and wear-resistance that extend blow mold operation time.

Request for a quoteResults for

Increasing hardness - Import exportNumber of results

31 ProductsCompany type

Category

- Tools & Hardware (12)

- Tools, pneumatic (4)

- Steel & Metals (3)

- Grinding - machine tools (2)

- Mechanical transmission systems and components (2)

- Water softeners (2)

- Blow moulding of rubber and plastic (1)

- Chemical catalysts (1)

- Industrial tools (1)

- Laser apparatus and instruments (1)

- Natural abrasives (1)

- Pipe and tube fittings - non-ferrous metal (1)