- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating components

Results for

Heating components - Import export

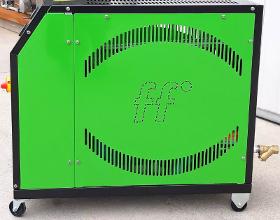

FRIGOFLUID S.R.L.

Italy

Most industrial process temperature control units work through the pressure exerted on the water of the process utilities: this is convenient in most “standard” cases, given the higher efficiency developed by the system. However, some critical process issues can make this type of operation difficult: this is the case of machines that leak fluids, or with leakage, and that it is not convenient to maintain on the spot. In such cases, it is therefore useful to work with a vacuum temperature control unit, which sucks in utility water. FTT PD water thermoregulators are flexible and effective systems, which can work under either pressure or vacuum depending on the peculiarities of the system. Any fluid losses are therefore minimized during operations. A simplicity of operation is also ensured by the touch-screen panel, also found on other Frigofluid temperature controllers. Models with an increased pump are also available for users characterized by high pressure drops.

Request for a quote

FRIGOFLUID S.R.L.

Italy

Often the main critical issue for molding industries is not achieving the temperatures needed for their processes, but maintaining them over time. Hence the usefulness of temperature control units that not only send the fluids needed to do the job up to temperature, but are capable of subsequent self-tuning. This is the way FTT DC water temperature controllers operate, which wrap direct cooling to stabilize fluid grades after the desired temperature has been reached. This requires integration with a source of cooled water: a simple well or a chiller or cooling system (chiller or dry cooler). Our engineers are available to determine which cooling solution is the most effective and economical. Not only that. The management of these successive heating-cooling steps is easier when done with a touch screen: a feature with which FTT DC temperature controllers are equipped. Units in the FTT category are specially designed to condition molds.

Request for a quote

FRIGOFLUID S.R.L.

Italy

FT water temperature controllers make it possible not only to cut down on the use of electrical power for heating (in fact, the heating elements remain off during steady-state operation), but they also make it possible to limit the cooling power spent on cooling by self-stabilizing through a process called Autotuning. This system also saves resources (water and energy) compared to units without them. They are designed to condition molds and cylinders for various industrial processes, including plastics and rubber molding and extrusion, and in the paper industry.

Request for a quote

S.C.E. COMPANY SRL

Italy

The heat exchanger is a component in which an exchange of thermal energy takes place between two fluids at different temperatures. In general, exchangers are open systems that operate without exchange of work, i.e. they present a constant flow of matter and a constant temperature distribution in steady state conditions. For this sector, our company deals with the production and sale of copper and iron pipes which can be semi-finished or assembled suitable for different purposes, including: Sensitive type exchanger, Cooler exchanger, Heater exchanger, Reboiler exchanger, Evaporator exchanger, Condenser exchanger

Request for a quote

SILGA SPA

Italy

IMS (Insulated metal substrate) technology allows the mounting of power components directly on a highly thermally conductive printed circuit board . The result is a compact and reliable solution which, thanks also to the reduced cost compared to systems with traditional heat sinks, is finding more and more application in sectors where effective dissipation of the heat generated by electronic components is required, such as of Lighting, Automotive and Power Supply . The devices can operate at lower temperatures with a guarantee of greater reliability and lifespan , avoiding the assembly phases of mechanical heat sinks. The assembly cycle is simplified and can in some cases be reduced to just the SMT assembly operation. The availability of dielectric layers of different nature and thickness offers many design possibilities from a thermal and electrical insulation point of view. It is possible to use different materials with both aluminum and

Request for a quote

UNISPECIAL S.R.L. - TURNING CENTER COMPANY

Italy

CNC machined parts and components made by milling and turning with machine centers and multi axix sliding head CNC lathes from alluminium, steel, plastics ecc. Application: heating, cooling and air conditioning systems and appliances

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Heating components - Import exportNumber of results

6 ProductsCountries