- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cast iron and castings

Results for

Cast iron and castings - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

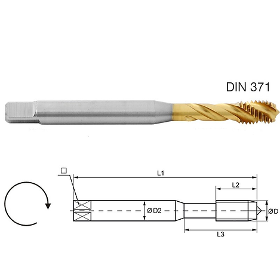

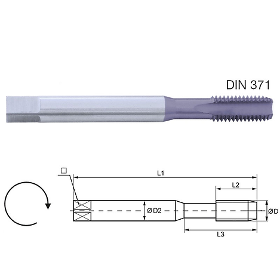

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

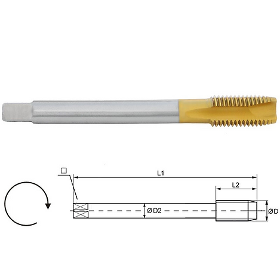

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

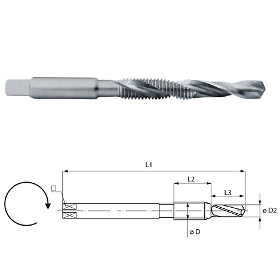

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

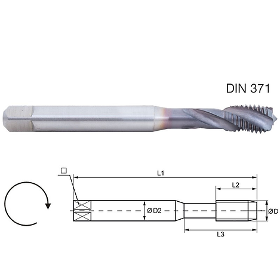

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For cast materials Material of product: HSSE Surface treatment: TiCN For materials: Grey cast iron, Aluminium casting alloy, Copper base alloys etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for short-chipping casting material. The TiCN surface treatment (titanium carbon nitride - grey violet) increases the surface hardness (approx. 3000 HV) and the sliding properties (coefficient of friction: 0,3). It provides a better cutting performance and increased tool life time. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Materials: Grey cast iron < 1000 N/mm² Aluminium casting alloy Si > 5% (short-chipping) up to 600 N/mm²

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Long version with three cutting holes, Ensat 308 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Similar to Ensat 307 but longer, so can be applied in thicker materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance Short version with three cutting holes, Ensat 307 standard Particularly designed for materials resistant to cutting and where you want to exclude any slight self-locking effect on the screw. With the same insertion torque, they exert a higher and better distributed cutting force compared to Ensat 302 inserts, having three cutting points instead of two. Also Ensat 307 inserts are shorter than Ensat 308 and therefore ideal on thinner materials These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.).

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality brass self-tapping ensat thread inserts. Particularly suitable for light metals and all types of plastics, both thermoplastics and thermosets This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality self-tapping ensat thread inserts. Made of ASIS 304 stainless steel This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality zinc plated steel self-tapping ensat thread inserts. Made of galvanized steel, conforming to RoHS, this ensures excellent wear and corrosion resistance This is the most popular model of self-tapping inserts with two cutting slots in the conical end part of the insert. Due to the cutting slots, the thread inserts remain anchored in the material even under strong shocks or vibrations. Suitable for most applications. Ensat 302 standard These inserts are self-tapping and do not require pre-threading. They can be easily installed by screwing them into the appropriately sized hole using the installation tool They are usually used to enforce or repair threads in metallic materials with low shear resistance (metal alloys, aluminum, cast iron, plastic, castings, etc.). These self-threading bushes have an internal thread for the screw and an external thread with cutting slots to insert itself into the material Made in the EU.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SARTEX S.R.L.

Italy

Pulley with cast iron wheel. Steel pin, hook and frame.

Request for a quote

DONATIF DI DONATI FILIP

Italy

Created from a cast iron body coated with thick, high-density rubber. Has 3 gripping handles. High relief weight. Tolerance +/- 1%. Made of top-quality materials.

Request for a quote

MORELLI STYLE

Italy

Catalogue dedicated to noaccess posts for car parks, pedestrian areas, parks and town squares in cast iron or metal and cast iron.

Request for a quote

REBEC SRL

Italy

Rebec supplies both flame lamination non-stop lines, with large production capacity and flame lamination lines with small and medium production capacity. Flame bonding machines can be simple, with manual adjustments or automatic adjustments of the working parameters by servo controls, PLC and PC. Our burners are made of cast iron made from solid bars. Cast iron burners have a longer life than aluminum burners especially if you process corrosive foams (some flame-retardant foams used for the automotive industry). In addition, the perforated ribbon to shape the flame slides on one side and therefore it can be easily and quickly removed for cleaning.

Request for a quoteResults for

Cast iron and castings - Import exportNumber of results

22 ProductsCountries

Company type